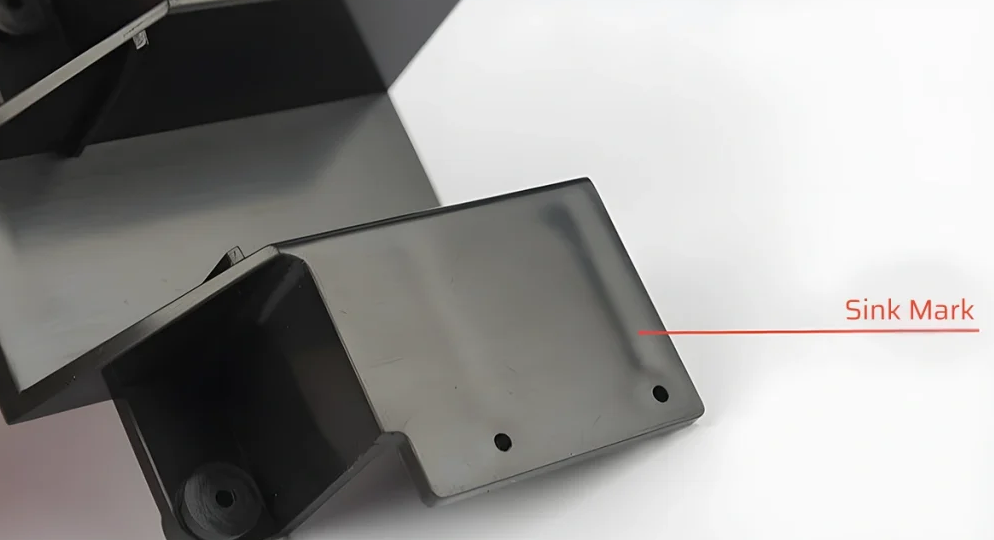

Avoiding sink marks in injection molding is crucial for achieving high-quality plastic parts with uniform surface appearance and dimensional accuracy. Sink marks typically occur due to uneven cooling and shrinkage of molten plastic inside the mold cavity. Here’s a detailed guide on how to avoid sink marks in injection molding:

1. Design Considerations

- Uniform Wall Thickness:

- Maintain consistent wall thickness throughout the part design. Variations in thickness lead to uneven cooling rates and differential shrinkage, causing sink marks.

- Use design guidelines that recommend adequate thickness to ensure proper flow and cooling of the plastic material.

- Avoid Sharp Corners and Edges:

- Round or fillet sharp corners and edges in the part design. Sharp features can create stress concentrations and uneven cooling, leading to sink marks.

- Incorporate generous radiuses or chamfers at transitions between thick and thin sections to promote uniform shrinkage.

- Rib Design:

- Use ribs or internal features to reinforce sections where thicker walls are required. Properly designed ribs can distribute stresses and reduce the likelihood of sink marks.

- Gating and Runner System:

- Optimize gate and runner design to facilitate uniform flow of molten plastic into the mold cavity.

- Properly position gates to minimize flow restrictions and ensure balanced filling of the cavity, reducing the risk of sink marks.

2. Mold Design and Tooling

- Cooling System:

- Design molds with an effective cooling system that evenly dissipates heat throughout the mold cavity.

- Ensure adequate cooling channels and proper placement to maintain consistent temperature and reduce uneven cooling that causes sink marks.

- Surface Finish:

- Use a textured mold surface finish or matte finish to reduce surface tension and promote uniform cooling.

- Avoid highly polished mold surfaces, which can increase the likelihood of sink marks due to slower cooling rates.

- Venting:

- Incorporate venting channels in the mold to allow trapped air to escape during the injection process.

- Proper venting prevents air pockets from forming, which can cause localized shrinkage and sink marks.

[elementor-template id=”4330″]

3. Injection Molding Process Optimization

- Injection Parameters:

- Optimize injection speed, pressure, and temperature settings to achieve uniform filling and packing of the mold cavity.

- Avoid overly high injection pressures that can induce internal stresses and contribute to sink marks.

- Gate Size and Location:

- Use appropriately sized gates to facilitate smooth flow of molten plastic into the cavity.

- Position gates to minimize flow length and pressure drop, ensuring uniform pressure distribution and reducing sink mark formation.

- Cooling Time and Pressure Holding:

- Set adequate cooling times to allow the part to solidify uniformly without premature ejection.

- Implement pressure holding to compensate for material shrinkage during cooling, reducing the formation of sink marks.

4. Material Selection

- Shrinkage Characteristics:

- Select plastic materials with lower shrinkage rates or materials that exhibit uniform shrinkage properties across the part.

- Consider using materials with additives or fillers that minimize shrinkage and improve dimensional stability.

5. Post-Molding Considerations

- Part Orientation and Ejection:

- Orient parts within the mold to minimize stress concentrations and uneven cooling.

- Use ejector pins and systems that apply uniform force to eject parts without causing deformation or sink marks.

- Inspection and Quality Control:

- Inspect molded parts for sink marks immediately after ejection.

- Implement quality control measures to monitor sink mark formation and identify potential causes for corrective action.

[elementor-template id=”4331″]

Conclusion

By integrating these design considerations, mold design strategies, process optimization techniques, and material selection criteria, manufacturers can effectively prevent sink marks in injection-molded parts. Addressing potential issues early in the design and development stages and continuously optimizing the injection molding process are key to achieving high-quality parts with minimal defects and consistent surface finish.

Related Conten: Expert Large Plastic Molds Manufacturing

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|