Flash in injection molding refers to excess material that flows outside the intended part cavity, typically along the parting line,…

Blogs

Avoiding air bubbles in injection molding is essential to ensure the quality and integrity of the molded parts. Air bubbles…

The duration of an injection molding cycle, often referred to as the cycle time, can vary widely depending on several…

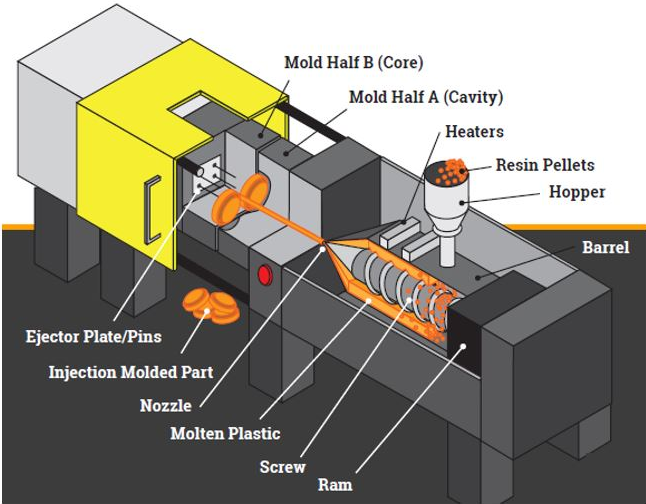

Injection molding involves various components and pieces of plastic at different stages of the process. Each of these pieces has…

Maintaining an injection mold machine involves various costs that can be categorized into routine maintenance, preventive maintenance, and unexpected repairs….

Injection molding is a versatile manufacturing process used to produce a wide range of plastic products. The choice of plastic…

Injection molding is a highly versatile and widely used manufacturing process for producing complex plastic parts. Here are the main…

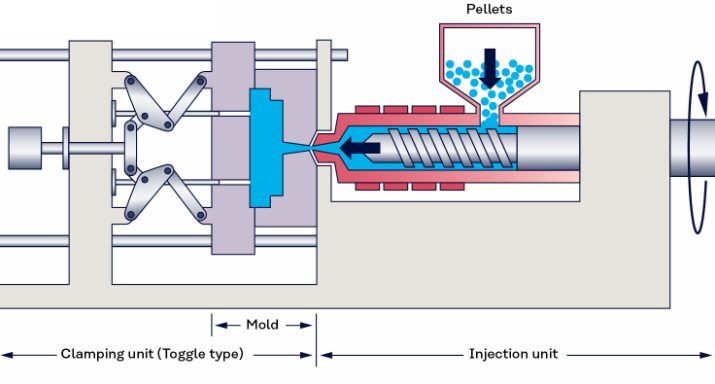

Injection molding is a widely used manufacturing process for producing plastic parts. The process can be broadly divided into two…

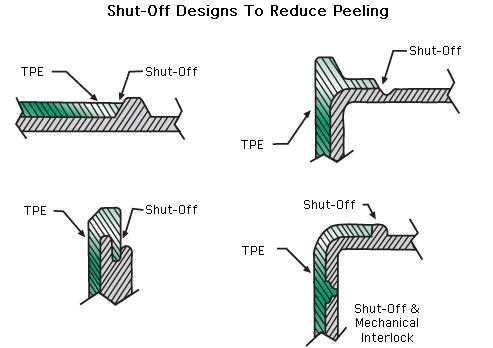

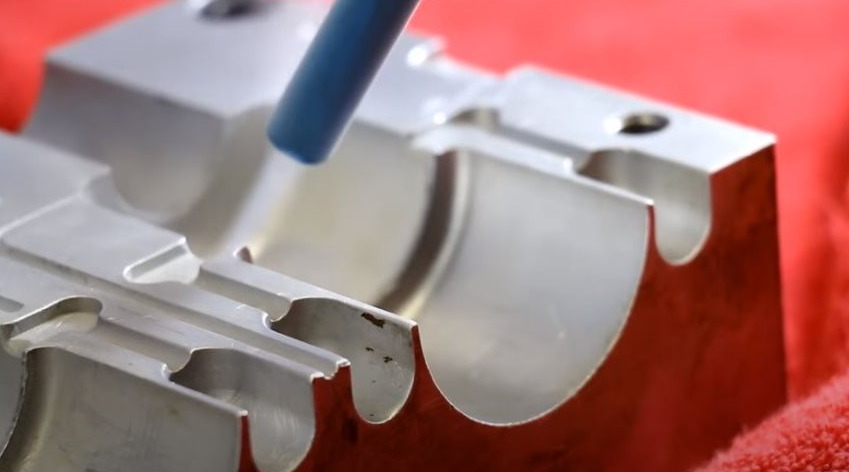

Shutoffs in injection molding refer to areas within a mold where two mold components come together to create a seal,…

Cleaning a plastic injection mold is essential for maintaining product quality, extending mold life, and ensuring consistent production performance. Proper…