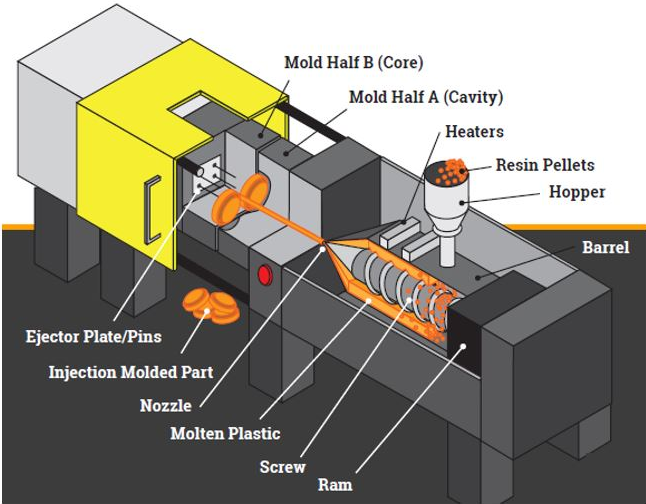

Injection molding involves various components and pieces of plastic at different stages of the process. Each of these pieces has specific names that are commonly used in the industry. Here are the key terms:

1. Resin/Pellets

Description:

- The raw plastic material used in the injection molding process. These are usually in the form of small granules or pellets.

Importance:

- The quality and type of resin determine the properties of the final molded part.

[elementor-template id=”4330″]

2. Melt

Description:

- The molten plastic that has been heated and is ready to be injected into the mold.

Importance:

- Proper melting of the resin is crucial for ensuring the material flows correctly into the mold cavities and fills them completely.

3. Sprue

Description:

- The channel through which the molten plastic travels from the injection nozzle to the runner system of the mold.

Importance:

- Ensures that the molten plastic reaches the runners and subsequently the mold cavities.

4. Runner

Description:

- A system of channels within the mold that guides the molten plastic from the sprue to the mold cavities.

Importance:

- Distributes the molten plastic evenly to all cavities in the mold, ensuring consistent part quality.

5. Gate

Description:

- The small opening through which the molten plastic enters the mold cavity from the runner system.

Importance:

- The design and placement of the gate affect the flow of plastic into the cavity and the quality of the final part.

[elementor-template id=”4331″]

6. Cavity

Description:

- The hollow space within the mold that gives the molten plastic its shape as it cools and solidifies.

Importance:

- Determines the final shape and features of the molded part. Multiple cavities can be used to produce several parts simultaneously.

7. Core

Description:

- The mold component that forms the internal features of the part. It works with the cavity to define the part’s geometry.

Importance:

- Creates internal shapes, holes, and other features within the molded part.

8. Part/Component

Description:

- The final molded piece that results from the injection molding process.

Importance:

- This is the usable product or part that meets the specified design and functional requirements.

9. Ejector Pin Marks

Description:

- Marks left on the part where the ejector pins pushed the part out of the mold.

Importance:

- Proper design and placement of ejector pins minimize visible marks and ensure smooth ejection of the part from the mold.

10. Flash

Description:

- Excess plastic that escapes from the mold cavity and forms a thin layer on the part, typically along the parting line.

Importance:

- Indicates issues with mold clamping or improper pressure settings. Needs to be trimmed off to meet part specifications.

11. Sprue Puller

Description:

- A feature or component that helps remove the sprue from the mold during the ejection phase.

Importance:

- Ensures smooth removal of the sprue and prevents damage to the molded part or the mold itself.

12. Cold Slug Well

Description:

- A small well in the runner system designed to trap the initial cold slug of plastic that enters the mold.

Importance:

- Prevents the cold slug from entering the cavity and causing defects in the part.

13. Vents

Description:

- Small channels that allow air to escape from the mold cavity as the molten plastic fills it.

Importance:

- Prevents air traps and voids in the final part, ensuring better surface quality and structural integrity.

Conclusion

Understanding the terminology of the various pieces of plastic and components involved in injection molding is essential for anyone working in or with the injection molding industry. Each piece, from the raw resin pellets to the final molded part, plays a critical role in ensuring the success of the injection molding process. Proper management and design of these elements lead to high-quality, consistent, and efficient production of plastic parts.

Related Conten: Injection Molding Factory

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|