Understanding Injection Points

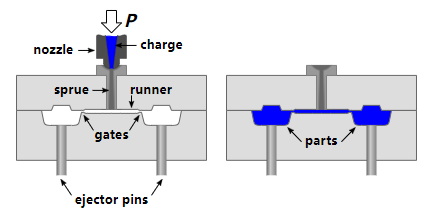

In injection molding, the point where molten plastic enters the mold cavity is crucial for ensuring the proper flow and distribution of the material. These entry points are known as gates. Gates are essential components of the mold’s runner system, which channels the plastic from the machine’s nozzle to the mold cavities.

Types of Gates

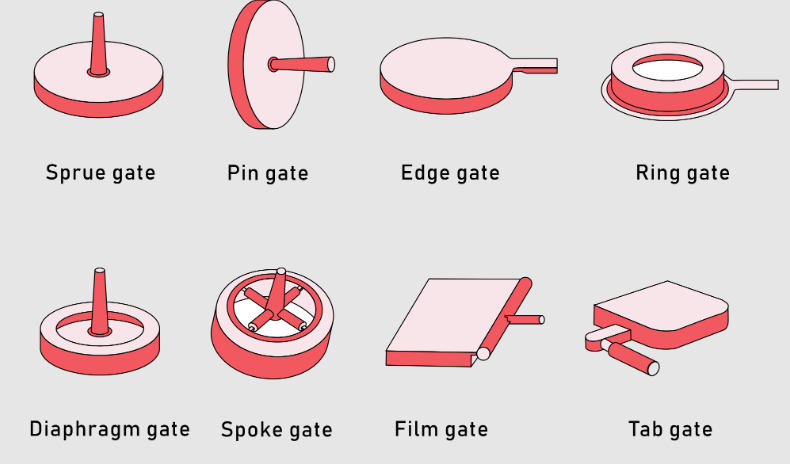

There are several types of gates used in injection molding, each with specific characteristics and suitable applications:

1. Edge Gate

- Description: Located on the edge of the part.

- Applications: Commonly used for simple parts with consistent wall thickness.

- Advantages: Easy to machine and maintain.

2. Submarine (Tunnel) Gate

- Description: Located beneath the part surface and enters at an angle.

- Applications: Used for parts requiring automatic degating.

- Advantages: Leaves a clean surface with minimal gate vestige.

[elementor-template id=”4330″]

3. Pin Gate

- Description: A small, cylindrical gate usually located at the center of the part.

- Applications: Suitable for symmetrical parts like caps and lids.

- Advantages: Provides balanced flow and minimizes weld lines.

4. Fan Gate

- Description: A wide, tapered gate that spreads the flow of plastic.

- Applications: Used for large, flat parts to ensure even filling.

- Advantages: Reduces warping and stress in the part.

5. Diaphragm Gate

- Description: Encircles the core of the part.

- Applications: Ideal for cylindrical parts like tubes and containers.

- Advantages: Ensures even filling and reduces internal stresses.

[elementor-template id=”4331″]

6. Cashew (Banana) Gate

- Description: A curved gate that enters the part from underneath.

- Applications: Used for parts with complex geometries.

- Advantages: Allows for hidden gate marks and easy automation.

7. Tab Gate

- Description: A rectangular gate attached to the part edge.

- Applications: Suitable for large parts or those requiring a large volume of material.

- Advantages: Ensures a strong and consistent flow of plastic.

8. Hot Runner Gate

- Description: Uses heated channels to keep the plastic molten until it reaches the cavity.

- Applications: High-volume production and complex parts.

- Advantages: Reduces waste and improves cycle time.

Considerations for Gate Selection

Choosing the right type of gate is crucial for optimizing the injection molding process. Factors to consider include:

- Part Geometry: Complex shapes may require specific gating to ensure complete filling and avoid defects.

- Material Properties: Different plastics flow and cool differently, influencing gate design.

- Aesthetic Requirements: Some applications require gates that leave minimal marks or can be hidden.

- Mechanical Requirements: The gate type can affect the strength and durability of the final part.

- Production Efficiency: Some gates are better suited for automated processes and high-volume production.

Conclusion

Injection points, or gates, play a vital role in the injection molding process by controlling how molten plastic enters the mold cavity. The choice of gate type affects the quality, efficiency, and aesthetics of the final product. Understanding the various gate types and their applications helps manufacturers optimize their injection molding processes to produce high-quality parts efficiently.

Related Conten: Plastic Parts Manufacturer

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|