Avoiding undercuts in injection molding is crucial to ensure that parts can be ejected from the mold without damaging either the part or the mold itself. Undercuts are features on the part that prevent it from being pulled straight out of the mold cavity. Here’s a comprehensive guide on how to avoid undercuts in injection molding:

1. Design Considerations

- Draft Angles:

- Design parts with sufficient draft angles on all vertical surfaces. Draft angles allow the part to release from the mold without getting stuck.

- Typically, a draft angle of 1-2 degrees per side is recommended for most materials. However, deeper or more complex undercuts may require larger draft angles or additional design considerations.

- Parting Line Design:

- Carefully plan the location of the parting line where the mold splits into two halves. Minimize undercuts near the parting line to simplify mold design and part ejection.

- Use parting lines strategically to separate sections of the mold that might otherwise create undercuts.

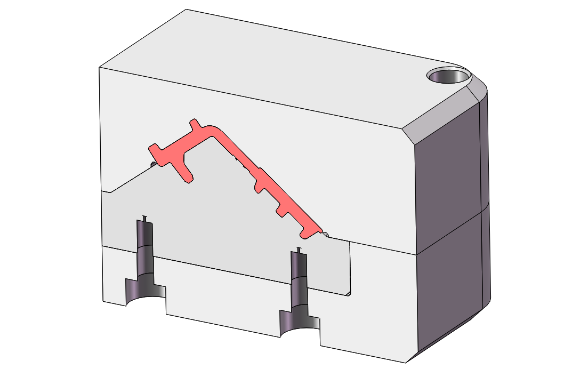

- Core Pullers and Slides:

- Incorporate mechanical features like core pullers or slides into the mold design to retract sections of the mold that would otherwise create undercuts.

- Core pullers are pins or slides that move perpendicular to the mold opening direction to release undercut features.

- Avoid Sharp Corners and Overhangs:

- Design parts with rounded edges and avoid sharp corners and overhangs that can create undercuts.

- Use fillets and radii to transition between different features and reduce stress concentrations that can lead to mold deformation or part sticking.

2. Mold Design

- Split Lines:

- Optimize the placement of mold split lines to avoid creating undercuts. Align split lines with parting lines and features that facilitate easy mold release.

- Minimize the complexity of the mold design around undercuts to simplify manufacturing and reduce costs.

- Core and Cavity Alignment:

- Ensure proper alignment between the core and cavity of the mold to prevent misalignment that could lead to undercuts.

- Use precision machining techniques to achieve tight tolerances and maintain alignment throughout the molding process.

- Use of Lifters or Inserts:

- Employ lifters or inserts in the mold design to create additional features that can release undercuts. Lifters are mechanical components that lift or rotate to release the part from the mold.

[elementor-template id=”4330″]

3. Material and Process Selection

- Material Flexibility:

- Choose materials with sufficient flexibility and elasticity to facilitate part release from the mold without causing damage.

- Some materials, such as certain types of thermoplastics and elastomers, are more suitable for molding intricate geometries with undercuts.

- Injection Molding Process Parameters:

- Optimize injection molding parameters such as temperature, pressure, and cooling time to minimize stress and distortion that could affect part ejection.

- Fine-tune the process to achieve uniform filling of the mold cavity and reduce the risk of defects near undercuts.

4. Post-Molding Considerations

- Manual or Automated Ejection:

- Plan for manual or automated ejection systems that safely remove parts from the mold without damaging undercuts.

- Ensure that ejection systems are aligned with the part design and mold features to prevent deformation or breakage.

- Quality Control and Inspection:

- Inspect molded parts for any signs of sticking or damage related to undercuts.

- Implement quality control measures to monitor part dimensions, surface finish, and overall quality to identify and address issues early in production.

[elementor-template id=”4331″]

Conclusion

By integrating these design considerations, mold design strategies, material selection criteria, and process optimization techniques, manufacturers can effectively avoid undercuts in injection-molded parts. Early collaboration between design engineers and mold designers, along with thorough prototyping and testing, are key to achieving high-quality parts with complex geometries and minimal production challenges.

Related Conten: Custom Plastic Fabrication

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|