OEM Plastic Injection Molding Car Parts PP Front Baffle – Injection Molding Automotive Parts Built for Consistent Fit

Product Overview

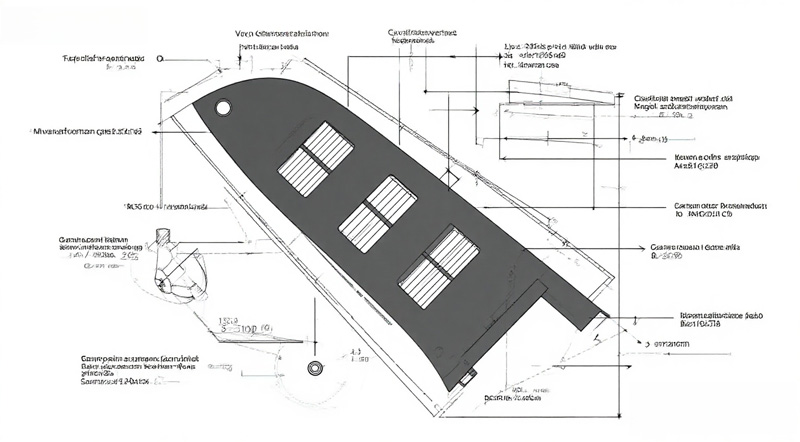

Our OEM Plastic Injection Molding Car Parts PP Front Baffle is a purpose-built component for modern vehicle platforms where lightweight design and reliable assembly matter significantly. This part is commonly used as a front baffle/air guide or protective panel within the front-end module, supporting airflow management, splash resistance, and structural integration around adjacent components.

It is clear that injection molding automotive parts must be engineered for repeatability. In our view, PP (polypropylene) is one of the most practical choices because it’s lightweight, durable, and typically cost-effective compared with many engineering plastics—especially when your program needs stable, high-volume output. Depending on your performance targets, we can use PP homopolymer, PP copolymer, or mineral/talc-filled PP to optimize stiffness, impact resistance, and heat performance.

If you’re sourcing injection molded car parts for OEM platforms, this PP front baffle is a proven, industry-standard solution engineered for fast assembly, consistent clip engagement, and reliable dimensional stability.

Pain Points

- Dimensional drift that causes assembly gaps, clip misalignment, or rattling in the vehicle front end

- Warping and sink marks from uneven wall thickness, poorly designed ribs, or suboptimal cooling

- Material inconsistency leading to brittle clips, stress whitening, or reduced impact performance

- Weak surface appearance from unstable process settings, flow lines, or inconsistent texture

- Supplier communication issues where DFM feedback is vague and changes happen too late

From our perspective, many buyers don’t just need a molded part—they need a predictable system. This indicates that strong DFM and process control are essential, especially when the part interfaces with multiple upstream and downstream assemblies.

Our Solutions

- DFM-first engineering: We advise that you validate wall thickness, rib ratios, and boss design early to reduce warpage and sink marks.

- Material guidance for PP baffles: We recommend impact-modified PP for cold-weather programs, and talc-filled PP when higher stiffness is needed.

- Optimized tooling strategy: Balanced gating, robust venting, and engineered cooling channels for stable cycle time and uniform shrink control.

- Process validation: T1 sampling with dimensional reports and fit checks, then parameter locking for repeatability.

- Quality control you can trust: CMM/fixture checks, appearance standards, and consistent traceability across lots.

In our experience, the best results happen when we treat the part as a functional interface, not just a plastic panel. Consequently, we focus on mounting features, clip retention, and datum strategy so assembly becomes simple and reliable.

Manufacturing Capabilities

- Plastic injection molding for interior and exterior automotive components

- Mold design & fabrication with in-house engineering support

- Insert molding / overmolding (when baffles require metal inserts or soft-touch interfaces)

- Assembly support including ultrasonic welding and mechanical fastening, if needed

- Surface finishing options such as texture, polishing, painting, and laser marking

Notably, when customers ask how to design injection molded parts that remain stable in production, we typically start with DFM simulations and practical tooling rules—because that’s where predictable quality is born. This highlights that strong front-end engineering saves time and cost later.

And yes—buyers often compare regional supply options like plastic injection molding Kansas City, injection molding Long Island, or injection molding North Carolina when building a supplier list. In our view, location is helpful, but process capability, QC discipline, and tooling expertise ultimately matter more for long-term program success.

Industries Served

- Automotive front-end modules and vehicle interior/exterior trim

- Consumer electronics housings and structural brackets

- Home appliances panels, ducts, and functional covers

- Industrial enclosures and protective components

- Medical non-critical housings (material dependent)

As a general observation, automotive programs demand consistent quality across large volumes. Therefore, our systems are optimized for repeatability, on-time delivery, and clear documentation that procurement teams can rely on.

Technical Specifications

Recommended Materials (PP-Focused)

- PP Homopolymer / PP Copolymer (impact-modified options available)

- Talc-filled PP (higher stiffness), glass/mineral-filled PP (application-dependent)

- Optional alternatives: ABS, PC/ABS, PA6/PA66 for higher heat or stiffness needs

Surface Finishing

- Matte / Texture (MT-style), Polishing, Painting (as required), Laser Marking

Mold Steel Options

- P20, 718H, NAK80, S136H, H13 (selected based on volume and resin)

Drawing Formats Accepted

- .stp / .step / .igs / .stl / .dwg / .pdf

Color Options

- Black/gray common for baffles; all PMS colors available for cosmetic variants

Tolerance Guidance

- Typically ±0.05 mm for general features; critical features can reach ±0.02 mm depending on geometry and measurement method

Mold Life

- 100,000 – 500,000 shots (depending on material, maintenance plan, and cavity design)

Packaging

- Bulk / Poly Bag / Bubble Bag / Carton / Custom Packaging with part protection for clips and edges

Why Choose Us

- 20+ years of mold manufacturing and injection molding experience

- ISO 9001:2015 quality management system

- In-house mold making for faster iteration and tighter control

- Strict QC: IQC → IPQC → FQC → OQC, with clear inspection records

- Fast lead time: samples in 7–10 days, mass production in 15–25 days (project-dependent)

- Flexible manufacturing: supports low MOQ, high-mix, and scaling programs

Customer feedback suggests that what buyers really want is peace of mind—clear timelines, reliable quality, and engineering support that actually responds. We believe that’s exactly what turns a supplier into a long-term partner.

Also, if you’re coordinating fixtures, inserts, or secondary operations, we can help you align with injection molding accessories suppliers so the full production ecosystem runs smoothly.

Production Flow

- Quote & Discussion (requirements, volume, resin, appearance standards)

- DFM Analysis (warpage risk, gate strategy, rib/boss optimization)

- Mold Design (cooling, venting, ejection, parting strategy)

- Mold Manufacturing (CNC/EDM, polishing/texture, assembly)

- T1 Sample & Testing (dimensional report, fit check, appearance review)

- Mold Optimization (parameter refinement, minor tooling adjustments if needed)

- Mass Production (locked process, consistent monitoring)

- QC Inspection (lot checks, critical feature control, traceability)

- Packing & Delivery (protective packaging, shipping per customer preference)

Internal Links

Related service: Plastic Injection Molding

Explore materials: Materials Library

See project examples: Case Studies

Learn the cooperation steps: Trade Process

Call to Action

Ready to Move Forward with a PP Front Baffle Program?

If you’re evaluating injection molding automotive parts suppliers, it is advisable to choose a team that can guide DFM decisions, control warpage, and deliver stable quality at scale. Send us your drawing and requirements—then we’ll respond with a practical quote and a clear manufacturing plan.

FAQ

What PP grade is best for an automotive front baffle?

Typically, impact-modified PP copolymer is a great starting point because it offers balanced toughness and moldability. However, for higher stiffness, talc-filled PP can be ideal. We recommend selecting the grade based on impact needs, heat exposure, and structural requirements.

How do you control warpage and shrinkage on large PP panels?

We focus on consistent wall thickness, rib design rules, balanced gating, and optimized cooling. In addition, we validate parameters during T1 and lock the process window. This demonstrates that good design plus stable processing is the real secret sauce.

What lead time should I expect for tooling and samples?

Tooling commonly takes 25–35 days depending on complexity. Samples are typically available in 7–10 days after tooling reaches the trial stage, and then we iterate quickly if adjustments are needed.

Can you support low-volume trials before mass production?

Yes—low MOQ and pilot runs are available. From our perspective, early validation significantly reduces risk, especially when you’re launching new injection molded car parts into a tight production schedule.

Do you help optimize the part design before tool build?

Absolutely. If you want to design injection molded parts that assemble reliably and look great, we’ll provide DFM feedback on ribs, bosses, draft angles, gating, and texture strategy. Ultimately, this saves cost and avoids unpleasant surprises.

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|