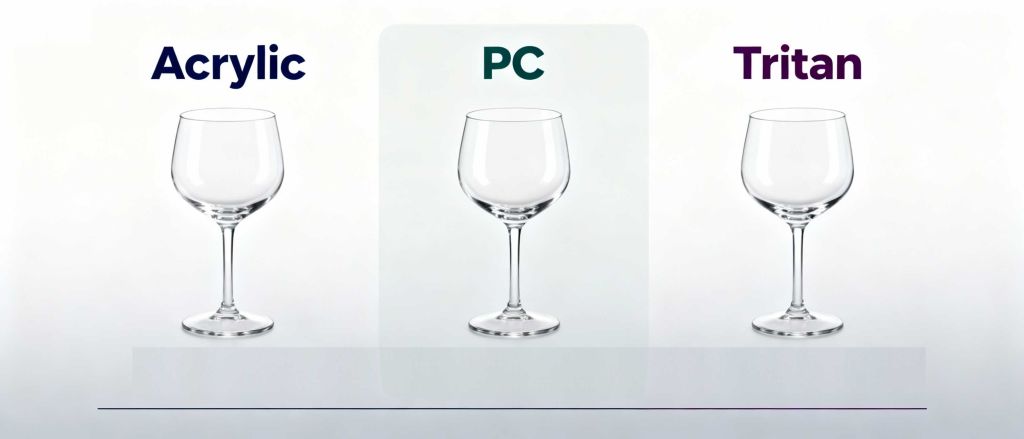

Choosing the right material for your wine glasses is essential for hospitality buyers, event planners and OEM brands. Acrylic (PMMA), Polycarbonate (PC) and Tritan (copolyester) each offer distinct benefits—clarity, impact resistance, or premium BPA-free safety. This guide explains material differences, the manufacturing flow from mold to finished product, decoration and OEM/custom options so you can confidently source the best solution for your project.

Key Highlights

- Ultra-clear, glass-like transparency (Acrylic & Tritan)

- Shatterproof options ideal for hospitality, outdoor events and high-traffic venues (PC)

- Multiple decoration methods—pad printing, UV, laser engraving, metallic rims

- Custom OEM/ODM services: molds, prototypes, low-volume runs and mass production

- Quality & compliance support: ISO 9001:2015, FDA, LFGB options

Specifications Overview

| Item | Acrylic (PMMA) | Polycarbonate (PC) | Tritan (Copolyester) |

|---|---|---|---|

| Clarity / Appearance | ★★★★★ Highly transparent, glass-like | ★★★★☆ Slight bluish tint | ★★★★★ Crystal-clear, colorless |

| Impact Resistance | ★★☆☆☆ | ★★★★★ Extremely impact-resistant | ★★★★☆ High-strength |

| Scratch Resistance | ★★★☆☆ | ★★☆☆☆ | ★★★★☆ |

| BPA | Optional | Specify BPA-Free | ✔ 100% BPA-Free |

| Dishwasher | Hand wash recommended | Commercial dishwasher-safe | Dishwasher-safe |

| Typical Uses | Outdoor events, wedding, promotional | Bars, hotels, catering | Premium hotels, gift sets |

| Cost Level | Low | Medium | High |

How Acrylic / PC / Tritan Wine Glasses Are Made

Wine Glasses Mold Design

The core to high-quality plastic drinkware is mold engineering. Engineers deliver CAD models optimized for wall thickness, draft angles, cooling paths and gate locations to preserve optical clarity and structural strength. Proper mold design reduces cycle time and material waste while enabling predictable mass production.

Wine Glasses Prototype Development

Prototypes validate balance, capacity and feel before mold fabrication. We offer soft tooling and low-volume prototypes to reduce risk and accelerate approval for OEM/ODM clients.

Wine Glasses Rapid 3D Printing

High-resolution 3D prints facilitate quick checks of ergonomics and proportions using EOS, HP or SLS systems. This allows rapid design iteration and stakeholder approvals.

Wine Glasses Mold Fabrication

Mold fabrication uses CNC machining, EDM, high-precision polishing and cavity texturing to replicate vertical patterns and ensure optical surfaces for Acrylic, PC or Tritan.

Wine Glasses Injection Molding Production

Our injection machines (80T–800T) are tuned by experienced technicians to control temperature, pressure and cooling, ensuring minimal flash and consistent part clarity.

Wine Glasses Surface Decoration & Finishing

We provide pad printing, screen printing, UV full-color printing, laser engraving and metallic finishes (PVD, hot foil) for logo and rim decoration. Molded textures are created directly in-cavity for durable tactile details.

OEM / Customization

We support full OEM/ODM workflows: custom shape, material selection, logo options, color tints, rim finishes and retail packaging. Our typical MOQ depends on whether you choose stock shapes or custom molds.

- Stock shapes: Low MOQ options to test market demand.

- Custom molds: Custom molds: Minimum order quantity to be confirmed with our sales team.

- Logo & Packaging: Laser, pad, UV printing; custom gift boxes and retail-ready packaging available.

Process: Share your drawing/CAD → design & quoting → prototype → mold → sample approval → mass production → delivery.

Quality Control & Certifications

Our QC follows ISO 9001:2015 standards. Key checks include raw material verification, first-shot tests, optical clarity inspection, drop and dishwasher tests, and surface finish control.

- Available certifications: FDA, LFGB, EU 10/2011, Prop 65 declarations

- Documentation: Material test reports, BPA-free declarations (for PC/Tritan), inspection reports

Application Scenarios

Acrylic, PC and Tritan wine glasses serve broad markets:

- Hospitality: Hotels, bars, catering and banquet halls

- Events: Weddings, outdoor parties, festivals

- Outdoor Lifestyle: Camping, poolside, beach resorts

- Retail & Gifts: Premium homeware collections and corporate gifts

Wine Glasses Drop Test Demonstration

Frequently Asked Questions (FAQ)

- Q1: Are Acrylic / PC / Tritan wine glasses dishwasher-safe?

- Acrylic: hand wash recommended. PC: typically commercial dishwasher-safe (confirm BPA-free grade). Tritan: generally dishwasher-safe and retains clarity after cycles.

- Q2: Can I add my logo or packaging?

- Yes — we support laser engraving, pad/UV printing, hot foil and custom retail packaging. We advise protective packing for PC to avoid surface scratches during transit.

- Q3: What is the lead time?

- Sample: 7–10 days. Mass production: typical 25–30 days after mold approval (dependent on order size & decoration complexity).

- Q4: What MOQ do you require for custom molds?

- Custom molds typically require MOQ in the 3,000–5,000 pcs range. Stock shapes are available with lower MOQs.

- Q5: Are your materials food-safe and certified?

- We can supply material certificates and test reports to meet FDA, LFGB and EU food contact requirements. Tritan carries the strongest BPA-free claims and is preferred for premium export markets.

Ready to Start Your Project?

DTG Tech offers end-to-end solutions—from design and prototyping to mold manufacturing and mass injection molding. Whether you need cost-effective Acrylic units for events, heavy-duty PC for hospitality, or premium Tritan for branded collections, we can tailor a solution.

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|