Stainless steel cannot be injection molded in the same way that thermoplastics are. However, there is a process known as Metal Injection Molding (MIM) that allows for the production of stainless steel parts. MIM combines the technologies of plastic injection molding and powdered metallurgy to produce complex, high-strength metal parts.

Key Considerations for Metal Injection Molding (MIM) with Stainless Steel

1. Material Preparation

- Feedstock: The feedstock used in MIM is a mixture of fine stainless steel powder and a thermoplastic binder. This mixture allows the metal powder to be shaped using injection molding techniques.

- Binder Removal: After molding, the binder is removed through a process called debinding, typically using solvents or thermal processes.

2. Molding Process

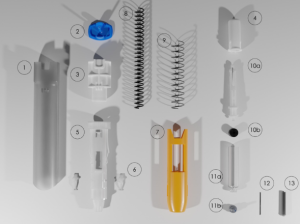

- Injection Molding: The feedstock is heated and injected into a mold cavity, similar to plastic injection molding. The mold shapes the material into the desired part geometry.

- Complex Geometries: MIM allows for the creation of complex shapes that would be difficult or impossible to achieve with traditional metalworking methods.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

3. Sintering

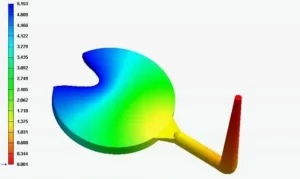

- High-Temperature Sintering: After debinding, the molded part, known as a “green part,” is sintered at high temperatures. Sintering fuses the metal particles together, resulting in a dense and strong final part.

- Shrinkage: Sintering typically causes shrinkage of about 15-20%, which must be accounted for in the initial design.

4. Post-Processing

- Finishing Operations: Depending on the application, parts may require additional finishing operations, such as machining, heat treatment, or surface finishing.

Advantages of Metal Injection Molding for Stainless Steel

1. Design Flexibility

- Complex Parts: MIM can produce parts with complex geometries, thin walls, and fine details that are difficult to achieve with traditional manufacturing processes.

- High Precision: The process offers high dimensional accuracy and repeatability.

2. Material Properties

- Mechanical Strength: Stainless steel parts produced by MIM have excellent mechanical properties, including high strength and hardness.

- Corrosion Resistance: Stainless steel is known for its corrosion resistance, making MIM parts suitable for harsh environments.

3. Cost-Effectiveness

- Mass Production: MIM is well-suited for high-volume production, offering economies of scale.

- Material Utilization: The process generates minimal waste compared to traditional metalworking methods.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Applications of Metal Injection Molded Stainless Steel

1. Automotive

- Engine Components: Used for manufacturing complex, high-strength components in automotive engines and transmissions.

- Fuel System Parts: Suitable for precision parts in fuel injection systems.

2. Medical Devices

- Surgical Instruments: MIM is used to produce high-precision surgical instruments and implants.

- Orthodontic Brackets: Stainless steel orthodontic brackets are commonly made using MIM.

3. Consumer Electronics

- Connectors and Housings: MIM allows for the production of small, intricate parts used in electronic devices.

4. Industrial Applications

- Gears and Bearings: Used for producing high-strength gears, bearings, and other mechanical components.

References

- Metal Injection Molding Association (MIMA): Provides detailed information on the MIM process and its applications.

- Advanced Powder Products (APP): Offers insights into the advantages and applications of MIM.

- GKN Powder Metallurgy: Discusses the benefits and uses of MIM for stainless steel parts.

Metal Injection Molding is an advanced manufacturing technique that enables the production of complex stainless steel parts with excellent properties, suitable for a wide range of applications across various industries.

Related Conten: Quick Turn Injection Molding