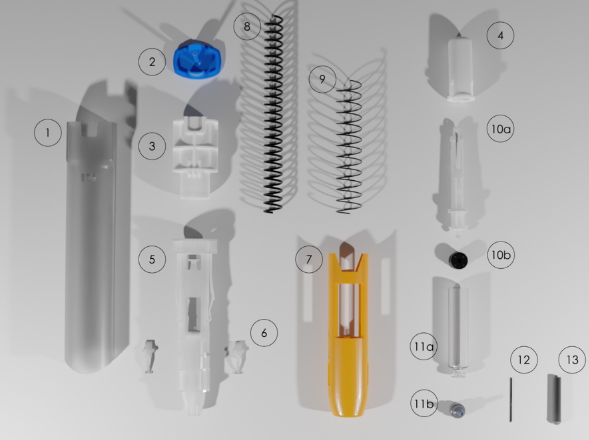

1. Outer Casing and Cap

- Material: Typically made from high-strength plastics like polycarbonate (PC) or acrylonitrile butadiene styrene (ABS).

- Process: Injection molding is used to create the outer casing and protective cap of the EpiPen. This ensures a durable and precise fit for the critical components inside.

2. Internal Components

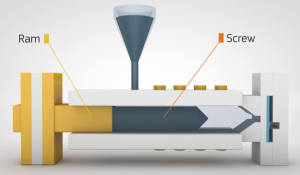

- Needle Shield and Plunger: Parts like the needle shield and plunger are also made using injection molding. These components require precise dimensions and smooth surfaces to function correctly.

- Spring Housing: The housing that contains the spring mechanism is injection molded to provide the necessary structural integrity and precision.

Why Injection Molding is Used for EpiPen Components

1. Precision and Consistency

- Tight Tolerances: Injection molding allows for the production of parts with very tight tolerances, which is crucial for the proper functioning of the auto-injector mechanism.

- Consistent Quality: The process ensures that each part is consistently produced to the same specifications, which is vital for medical devices.

2. Material Properties

- Durability: Materials used in injection molding, like polycarbonate and ABS, offer high strength and impact resistance, ensuring the EpiPen can withstand rough handling.

- Biocompatibility: The plastics used are often chosen for their biocompatibility, ensuring they are safe for use in medical applications.

Your Partner in Custom Injection Molding

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

3. Efficiency

- High-Volume Production: Injection molding is highly efficient for producing large quantities of parts quickly and cost-effectively, meeting the high demand for EpiPens.

- Cost-Effective: Once the molds are created, the cost per part is relatively low, making it an economical choice for manufacturing.

4. Design Flexibility

- Complex Geometries: Injection molding allows for the creation of complex part geometries, which can integrate multiple features into a single part, reducing assembly time and increasing reliability.

Conclusion

Yes, several components of EpiPens are produced using injection molding. This manufacturing method is ideal for creating the precise, durable, and high-quality plastic parts required for the reliable operation of these critical medical devices. Injection molding ensures that each EpiPen meets stringent safety and performance standards, providing patients with a dependable emergency treatment option.

Related Conten: Plastic Blow Molding