Yes, PET (Polyethylene Terephthalate) can be injection molded. PET is a widely used thermoplastic polymer known for its excellent strength, clarity, and barrier properties. It is commonly used in the packaging industry, especially for making bottles and containers, but also finds applications in automotive, electronics, and other industries. Here’s a detailed look at PET injection molding:

Properties of PET

- High Strength and Stiffness:

- PET offers good mechanical strength and stiffness, making it suitable for various structural applications.

- Clarity:

- PET has excellent optical clarity, which is why it is commonly used for clear containers and bottles.

- Chemical Resistance:

- It is resistant to many chemicals, including oils, acids, and alcohols, but can be affected by alkalis.

- Barrier Properties:

- PET has good barrier properties against gases and moisture, making it ideal for food and beverage packaging.

- Recyclability:

- PET is highly recyclable, which makes it an environmentally friendly material.

Applications of PET Injection Molding

- Packaging:

- Bottles for beverages, containers for food, and cosmetic packaging.

- Automotive:

- Components such as headlamp reflectors and other parts requiring good chemical resistance and strength.

- Electronics:

- Electrical insulators, housings, and components due to its dielectric properties.

- Consumer Goods:

- Items such as kitchenware, toys, and household products.

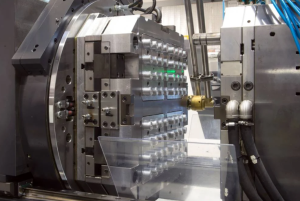

Injection Molding Process for PET

- Material Preparation:

- PET must be thoroughly dried before processing to prevent moisture-related defects. Typical drying conditions are 150°C to 160°C (302°F to 320°F) for 4-6 hours.

- Injection Molding Machine Setup:

- Temperature Settings: Barrel temperatures are usually set between 250°C to 280°C (482°F to 536°F), with mold temperatures between 80°C to 120°C (176°F to 248°F).

- Injection Pressure: Typically ranges from 600 to 1300 psi, depending on part geometry and material viscosity.

- Cooling Time: Adequate cooling time is essential to ensure part stability and prevent warpage.

- Molding Cycle:

- Injection: The molten PET is injected into the mold cavity under high pressure.

- Cooling: The part cools and solidifies in the mold. Cooling time depends on part thickness and mold temperature.

- Ejection: Once solidified, the part is ejected from the mold.

- Post-Processing:

- Parts may require trimming to remove excess material or flash.

- Additional finishing processes, such as annealing or surface treatment, may be applied to enhance properties and appearance.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Benefits of Using PET in Injection Molding

- Clarity and Aesthetics: Ideal for clear and transparent parts.

- Strength and Durability: Suitable for high-stress applications.

- Chemical Resistance: Effective for packaging and industrial applications.

- Barrier Properties: Excellent for preserving the contents of packaging.

- Recyclability: Environmentally friendly and widely recycled.

Considerations

- Moisture Sensitivity:

- PET is hygroscopic and must be dried properly before processing to avoid hydrolysis, which can degrade the polymer.

- Processing Conditions:

- Precise control of temperature and pressure is necessary to achieve high-quality parts and prevent defects such as voids, warpage, or crystallization.

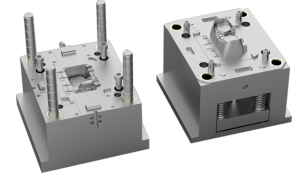

- Mold Design:

- Proper mold design, including adequate cooling and venting systems, is essential to ensure part quality and efficient production.

- Shrinkage:

- PET exhibits some shrinkage during cooling. Design considerations must account for this to ensure dimensional accuracy.

Conclusion

PET is an excellent material for injection molding, offering a combination of clarity, strength, and chemical resistance. It is widely used in packaging, automotive, electronics, and consumer goods industries. Proper material preparation, machine setup, and mold design are critical to achieving high-quality PET injection-molded parts. By carefully managing these factors, manufacturers can fully exploit PET’s benefits to produce durable, aesthetically pleasing, and functional components.

Related Conten: Quick Turn Injection Molding