1. Production Efficiency

- Speed and Cost: Thermoforming and extrusion processes are much faster and more cost-effective for producing large quantities of disposable cups compared to injection molding.

2. Material Suitability

- Plastic Sheets: Thermoforming uses plastic sheets, which are heated and then formed into cups. This is more efficient than the injection molding process, which requires heating and injecting plastic into a mold.

- Thin Walls: Thermoforming is particularly suited to creating the thin walls of disposable cups, which is challenging to achieve consistently with injection molding.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Common Manufacturing Processes for Disposable Cups

1. Thermoforming

- Process:

- Plastic sheets are heated until pliable.

- The heated sheet is then formed into the shape of a cup using a mold and vacuum or pressure.

- The formed cups are trimmed to their final shape.

- Advantages:

- High production speeds.

- Lower material costs.

- Ideal for producing lightweight and thin-walled items.

2. Extrusion and Forming

- Extrusion:

- Plastic material is extruded into a continuous sheet.

- The sheet is then fed into a forming machine where it is heated and formed into cups.

- Forming:

- Similar to thermoforming but starts directly from extruded plastic instead of pre-formed sheets.

- Advantages:

- High efficiency and speed.

- Suitable for high-volume production.

- Can produce consistent and uniform products.

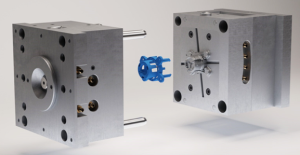

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Materials Used in Disposable Cups

- Polystyrene (PS): Commonly used for its clarity and rigidity, suitable for cold drinks.

- Polypropylene (PP): More flexible and can withstand higher temperatures, suitable for hot drinks.

- Polyethylene Terephthalate (PET): Used for its strength and clarity, often for clear cups.

Conclusion

Disposable cups are primarily made using thermoforming or extrusion and forming processes, not injection molding. These methods are more suitable for producing the thin-walled, lightweight, and high-volume characteristics required for disposable cups. The choice of material and manufacturing method ensures that the cups are produced efficiently and cost-effectively.

Related Conten: Plastic Injection Molding