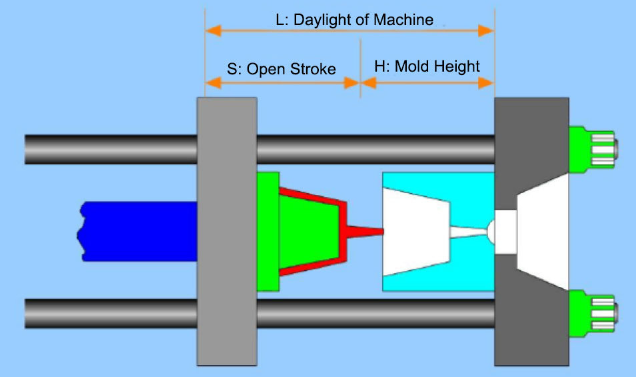

In an injection molding machine, “daylight” refers to the maximum distance between the two platens when the mold is fully open. It is a critical specification that determines the size of the mold that can be accommodated by the machine and the range of part sizes that can be produced.

Key Aspects of Daylight in Injection Molding

- Definition

- Daylight: The term “daylight” is used to describe the maximum open distance between the stationary platen and the moving platen of an injection molding machine. This distance is measured when the mold is completely open.

- Components Related to Daylight

- Stationary Platen: The fixed part of the machine to which one half of the mold is attached.

- Moving Platen: The movable part of the machine to which the other half of the mold is attached. It moves to open and close the mold during the molding cycle.

- Importance of Daylight

- Mold Accommodation: The daylight measurement determines the maximum mold height (including both halves of the mold and any necessary support structures) that the machine can handle.

- Part Ejection: Adequate daylight is necessary to allow for the ejection of the molded part. If the part is tall or requires complex ejection mechanisms, sufficient daylight ensures that the part can be removed without damage.

- Mold Installation and Removal: Adequate daylight facilitates the easy installation and removal of molds, which is important for maintenance and mold changes.

- Factors Influencing Daylight

- Machine Size: Larger injection molding machines typically have greater daylight distances, allowing for the use of larger molds and the production of larger parts.

- Tie Bar Spacing: The spacing between the tie bars, which are the structural supports of the machine, also affects the maximum mold size that can be accommodated.

- Adjustability

- Hydraulic Systems: Many modern injection molding machines use hydraulic systems that allow for the adjustment of the platen positions and, consequently, the daylight distance.

- Machine Settings: The daylight distance can be adjusted within certain limits to accommodate different mold sizes and to optimize the molding process.

Applications and Considerations

- Selection of Injection Molding Machine

- When selecting an injection molding machine, manufacturers consider the daylight distance to ensure that it can accommodate the specific molds required for their production needs. This involves taking into account the height of the mold halves and any additional space needed for ejector systems or mold inserts.

- Optimizing Production

- Adequate daylight allows for flexibility in production, enabling the use of a variety of molds with different sizes and configurations. This flexibility is especially important for manufacturers that produce a range of parts with different dimensions.

- Safety and Efficiency

- Proper daylight settings ensure that there is enough space for safe and efficient operation, including part ejection and mold changes. Insufficient daylight can lead to operational difficulties and potential damage to the mold or machine.

[elementor-template id=”4330″]

Example Calculation

If a mold consists of two halves, each 200 mm in height, and requires an additional 50 mm for the ejection mechanism, the total height of the mold setup would be 450 mm. Therefore, the machine’s daylight must be at least 450 mm to accommodate this mold.

Daylight=Height of Mold Half 1+Height of Mold Half 2+Height for Ejection Mechanism

Daylight=200mm+200mm+50mm=450mm

In this example, the injection molding machine must have a minimum daylight of 450 mm to properly fit and operate with this specific mold setup.

Conclusion

Daylight in an injection molding machine is a crucial specification that defines the maximum open distance between the platens. It is essential for accommodating molds of various sizes, ensuring proper part ejection, and facilitating mold installation and removal. When selecting and setting up an injection molding machine, adequate daylight ensures safe, efficient, and flexible production capabilities.

Related Conten: Injection Molding Factory / Plastic Parts Manufacturer

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|