Custom injection molding is a specialized manufacturing process where injection molding is tailored to meet the specific requirements and specifications of a client’s unique design or application. This customization can involve a wide range of adjustments and special considerations to produce parts that meet precise functional, aesthetic, and performance criteria.

Key Aspects of Custom Injection Molding

- Tailored Design and Engineering

- Custom Mold Design: The molds (or tooling) are designed specifically for the client’s product, considering the unique dimensions, geometries, and features required.

- Material Selection: Custom injection molding often involves selecting the appropriate plastic materials that meet the specific mechanical, thermal, and chemical properties needed for the part.

- Specialized Process Parameters

- Injection Parameters: The injection molding machine settings, including temperature, pressure, and cycle time, are optimized for the specific material and part design.

- Quality Control: Customized quality assurance processes are implemented to ensure that the parts meet the client’s standards and specifications.

- Prototyping and Testing

- Prototype Development: Custom injection molding typically involves creating prototypes to validate the design, material choice, and manufacturing process.

- Testing and Validation: Rigorous testing is conducted to ensure the parts perform as required under expected conditions.

- Tooling and Mold Fabrication

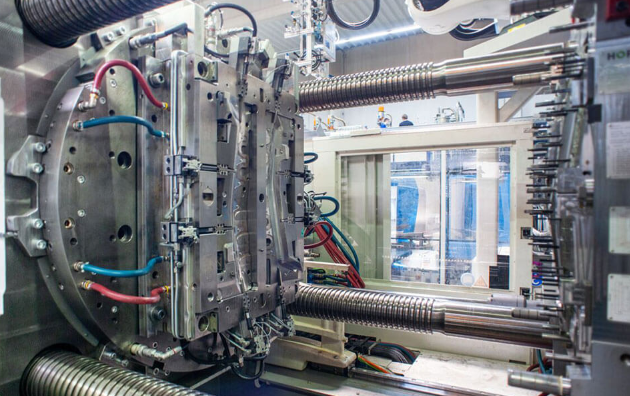

- Custom Tooling: The molds are often highly specialized and designed with specific features such as complex geometries, undercuts, or multi-material capabilities.

- Mold Fabrication: Advanced manufacturing techniques, including CNC machining, EDM (electrical discharge machining), and 3D printing for conformal cooling channels, are used to create high-precision molds.

- Production Flexibility

- Low to High Volume: Custom injection molding can be adapted for both low-volume prototyping and high-volume production runs, depending on the client’s needs.

- Post-Processing: Custom parts may require additional post-processing steps such as painting, coating, assembly, or secondary machining.

[elementor-template id=”4330″]

Benefits of Custom Injection Molding

- Design Flexibility

- Complex Geometries: Allows for the creation of complex and intricate part designs that standard molds and processes might not be able to produce.

- Specific Features: Customization enables the incorporation of specific features such as threaded inserts, overmolding, and multi-material components.

- Enhanced Performance

- Material Properties: Custom injection molding allows the selection of materials that provide the necessary strength, flexibility, resistance, or other properties required for the application.

- Precision: Ensures high precision and tight tolerances, which are critical for parts that need to fit together perfectly or perform specific functions.

- Cost Efficiency

- Reduced Waste: Optimized mold design and process parameters reduce material waste and increase efficiency.

- Long-Term Savings: Although initial tooling costs might be higher, custom molds designed for efficiency and longevity can lead to cost savings over time through improved cycle times and reduced defect rates.

- Competitive Advantage

- Unique Products: Custom injection molding allows companies to produce unique, differentiated products that meet specific market needs.

- Branding: Custom parts can incorporate branding elements such as logos or specific design aesthetics, enhancing product recognition and value.

[elementor-template id=”4331″]

Applications of Custom Injection Molding

- Automotive Industry

- Production of specialized components such as dashboards, lighting systems, and engine parts that meet stringent safety and performance standards.

- Medical Devices

- Manufacturing of medical components and devices that require biocompatibility, precision, and cleanliness, such as syringes, implants, and diagnostic equipment.

- Consumer Goods

- Custom parts for electronics, appliances, and household items that require unique designs, functional features, and aesthetic appeal.

- Industrial and Aerospace

- Production of durable and high-performance components used in machinery, aircraft, and other industrial applications that require specialized materials and precise engineering.

Conclusion

Custom injection molding is a versatile and highly specialized manufacturing process tailored to produce parts that meet specific client requirements. It involves customized mold design, material selection, process optimization, and rigorous testing to ensure high-quality, precise, and functional parts. This approach offers significant benefits in terms of design flexibility, performance, cost efficiency, and competitive advantage, making it ideal for a wide range of industries and applications.

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|