Making a fiberglass mold involves creating a sturdy and precise mold from which you can produce fiberglass parts. Here’s a step-by-step guide to help you through the process:

Materials and Tools Needed

- Fiberglass Cloth: Woven fiberglass fabric.

- Epoxy or Polyester Resin: Used to bond the fiberglass layers.

- Release Agent: To prevent the fiberglass from sticking to the mold.

- Gel Coat: Optional, for a smooth, glossy finish.

- Fiberglass Resin Brush or Roller: For applying the resin.

- Mixing Containers and Stir Sticks: For preparing the resin.

- Protective Gear: Gloves, goggles, and a respirator for safety.

- Sandpaper: For smoothing surfaces.

- Clay or Foam: For creating the original pattern (if needed).

- Mold Release Tape: For creating clean lines and edges.

Steps to Make a Fiberglass Mold

1. Create the Original Pattern

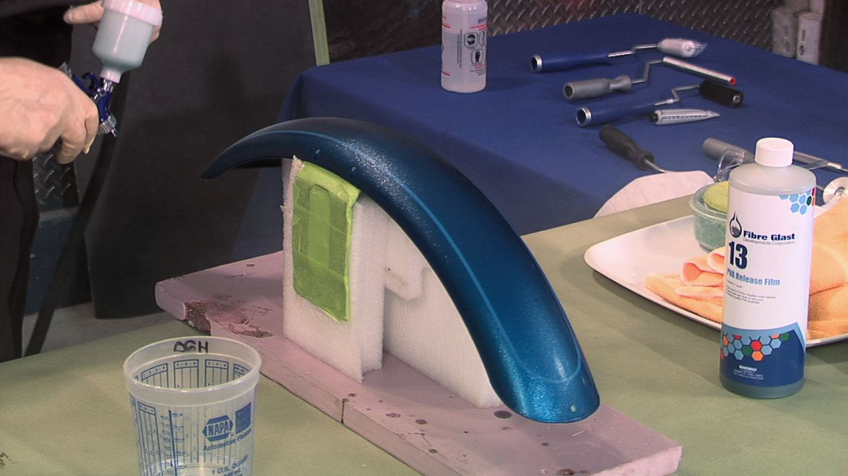

- Design Your Pattern: Decide on the shape and dimensions of the final product. You can use clay, foam, or any other material to create the original model.

- Refine the Pattern: Ensure the surface of the pattern is smooth and free of imperfections. Sand it if necessary and apply a primer if needed.

2. Apply a Release Agent

- Prepare the Surface: Clean the pattern thoroughly to remove dust and grease.

- Apply Release Agent: Use a brush or spray to apply a release agent evenly over the pattern. This will help in removing the mold from the pattern later. Allow it to dry completely before proceeding.

3. Apply the Gel Coat (Optional)

- Mix the Gel Coat: If you want a smooth, glossy surface, apply a gel coat before laying down the fiberglass.

- Apply Gel Coat: Use a brush or roller to apply an even coat of gel coat over the pattern. Allow it to cure as per the manufacturer’s instructions.

4. Lay Down the Fiberglass Layers

- Prepare the Resin: Mix the resin with the hardener according to the manufacturer’s instructions. Be sure to work in a well-ventilated area and wear protective gear.

- Cut Fiberglass Cloth: Cut the fiberglass cloth into manageable pieces or strips.

- Apply Resin: Brush a thin layer of resin onto the pattern.

- Lay the Fiberglass Cloth: Lay the cut pieces of fiberglass cloth onto the wet resin. Use a brush or roller to apply more resin over the cloth, ensuring it is fully saturated.

- Build Up Layers: Apply additional layers of resin and fiberglass cloth, allowing each layer to cure slightly before applying the next. Typically, 3-5 layers are sufficient for most molds.

5. Create a Support Shell

- Reinforce the Mold: Once the fiberglass layers have cured, add a support shell to reinforce the mold. This can be done using additional fiberglass layers or a rigid backing material like plywood or foam.

- Apply Additional Layers: If needed, apply more layers of resin and fiberglass to strengthen the mold.

6. Remove the Mold

- Check for Curing: Ensure the mold has fully cured before attempting to remove it from the pattern.

- Remove the Mold: Carefully peel the fiberglass mold away from the pattern. If it’s stuck, gently tap or use tools to help separate it.

7. Finish the Mold

- Clean and Sand: Sand any rough edges or imperfections on the mold. You may need to apply additional coats of resin to smooth out the surface.

- Apply Release Agent: Before using the mold for production, apply a release agent to prevent the fiberglass part from sticking to the mold.

8. Test the Mold

- Make a Test Part: To ensure everything is functioning correctly, make a test part using the mold. Check for fit and finish, and make any necessary adjustments to the mold.

Tips for Success

- Work in a Well-Ventilated Area: Resin fumes can be harmful. Always work in a well-ventilated space or use appropriate respiratory protection.

- Temperature Control: Resin curing times can be affected by temperature. Follow the manufacturer’s recommendations for optimal results.

- Keep Tools Clean: Clean brushes and other tools promptly to avoid hardened resin buildup.

By following these steps, you can create a durable and precise fiberglass mold suitable for various applications, from automotive parts to artistic projects.

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|