The cost of injection molds can vary widely depending on various factors such as complexity, size, material, and production volume. Here’s a breakdown of the primary cost factors and an estimation of the range of costs for injection molds:

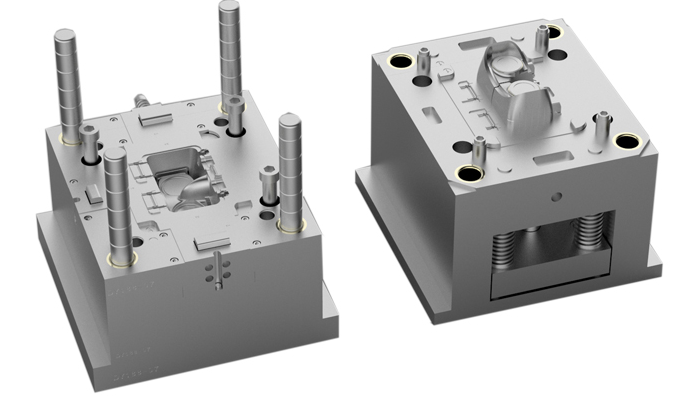

1. Complexity of the Design

Simple Molds

- Cost: $3,000 to $10,000

- Description: Basic designs with minimal features and fewer cavities.

- Cost: $25,000 to over $100,000

- Description: Intricate designs with multiple cavities, complex geometries, or moving parts (e.g., sliders or lifters).

[elementor-template id=”4330″]

2. Size of the Mold

Small Molds

- Cost: $3,000 to $15,000

- Description: Molds for small parts like caps, small toys, or simple components.

Large Molds

- Cost: $50,000 to $150,000 or more

- Description: Molds for bigger parts like automotive components or large housings.

3. Type of Material

Aluminum Molds

- Cost: $3,000 to $20,000

- Description: Easier to machine and suitable for low to medium production volumes.

Steel Molds

- Cost: $20,000 to $100,000 or more

- Description: More durable and ideal for high-volume production but more expensive.

4. Production Volume

Low Volume (1,000-10,000 units)

- Cost: $1,000 to $5,000

- Description: Prototype molds or short-run molds for low production volumes.

Medium Volume (10,000-100,000 units)

- Cost: $10,000 to $50,000

- Description: Molds suitable for small to medium-sized production runs.

High Volume (100,000+ units)

- Cost: $50,000 to $150,000 or more

- Description: Molds designed for mass production and large-scale manufacturing.

Additional Features

Multiple Cavities

- Cost: $50,000 to $200,000

- Description: Molds with more cavities to reduce the cost per part but increase the initial mold cost.

Hot Runner Systems

- Cost: 30-50% more than equivalent cold runner molds

- Description: More efficient for high-volume production, but add to the cost.

High Precision and Special Finishes

- Cost: 20-30% more expensive than standard molds

- Description: Molds requiring high precision, mirror finishes, or textured surfaces.

[elementor-template id=”4331″]

Example Cost Breakdown

For a mid-sized, moderately complex part with a production volume of 50,000 units:

Initial Costs

- Mold Design and Engineering: $5,000

- Single-Cavity Aluminum Mold: $15,000

Total Initial Mold Costs: $20,000

Conclusion

The cost of an injection mold depends on multiple factors, including complexity, size, material, and production volume. While the initial investment for molds can be substantial, especially for high-volume and complex molds, the per-unit cost decreases significantly with larger production runs. By carefully considering these factors, businesses can better estimate and manage the costs associated with injection molding.

Related Conten: https://www.m-dtg.com/landing-page/custom-molders-corp/

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|