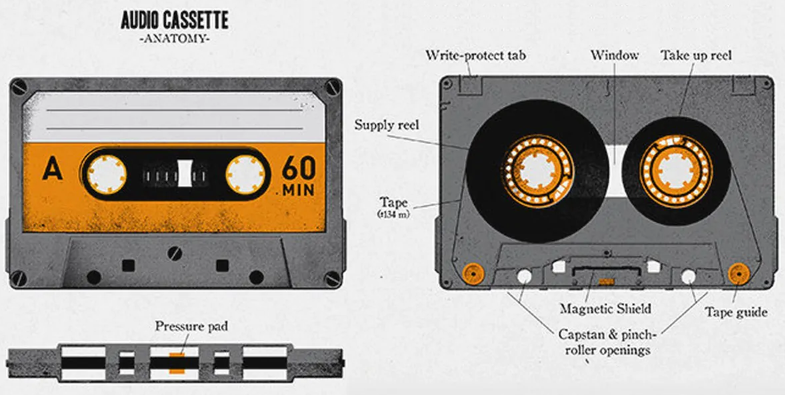

1. Cassette Shell (Case)

- Material: Typically made from high-impact polystyrene (HIPS) or acrylonitrile butadiene styrene (ABS) for durability.

- Process: Injection molding is used to create the two halves of the cassette shell, which house the tape and other internal components. The mold is designed to include precise details such as the openings for the tape spools, windows, and the notches for screws.

2. Spools (Reels)

- Material: Often made from the same plastic as the shell, such as HIPS or ABS.

- Process: Injection molding creates the spools that hold the magnetic tape. These need to be precisely molded to ensure smooth rotation and consistent tape tension.

3. Other Plastic Parts

- Guides and Rollers: These small components that guide the tape within the shell are also typically injection molded.

- Screws and Fasteners: While not always injection molded, some of the small clips or fasteners inside the cassette might be produced this way.

Advantages of Injection Molding for Cassette Tapes

1. Precision and Consistency

- Injection molding allows for the production of highly precise and consistent parts, which is critical for the proper functioning of cassette tapes. The components must fit together perfectly to ensure smooth operation and avoid damage to the magnetic tape.

2. Efficiency

- Injection molding is ideal for high-volume production, which was essential during the peak years of cassette tape popularity. The process allows for rapid manufacturing of large quantities of parts with minimal variation.

3. Cost-Effectiveness

- Once the molds are created, the cost per part in injection molding is relatively low, making it a cost-effective method for producing the millions of cassette tapes that were sold.

4. Material Versatility

- Injection molding supports a variety of plastics, allowing manufacturers to choose materials that offer the desired balance of strength, durability, and cost.

[elementor-template id=”4330″]

Conclusion

Cassette tapes involve several components that are produced using injection molding, such as the shell and spools. Injection molding is well-suited for manufacturing these parts due to its ability to produce high-precision, consistent, and cost-effective components in large volumes. This manufacturing process was integral to the widespread adoption and use of cassette tapes.

Related Conten: Prototype Manufacturing

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|