In the world of RV customization, every detail matters, from comfort features to the aesthetics of the interior. One critical component that is often overlooked is the air vent system. Air vents are integral to a motorhome’s air conditioning system, and understanding how they are made can help you choose the best options for your RV. A growing trend in RV customization is the use of plastic injection molding for creating durable, functional, and customized air vents. In this article, we will explore the process of plastic injection molding, its role in RV air vent systems, and how customized motorhomes feature plastic air vents to enhance both functionality and design.

What is Plastic Injection Molding?

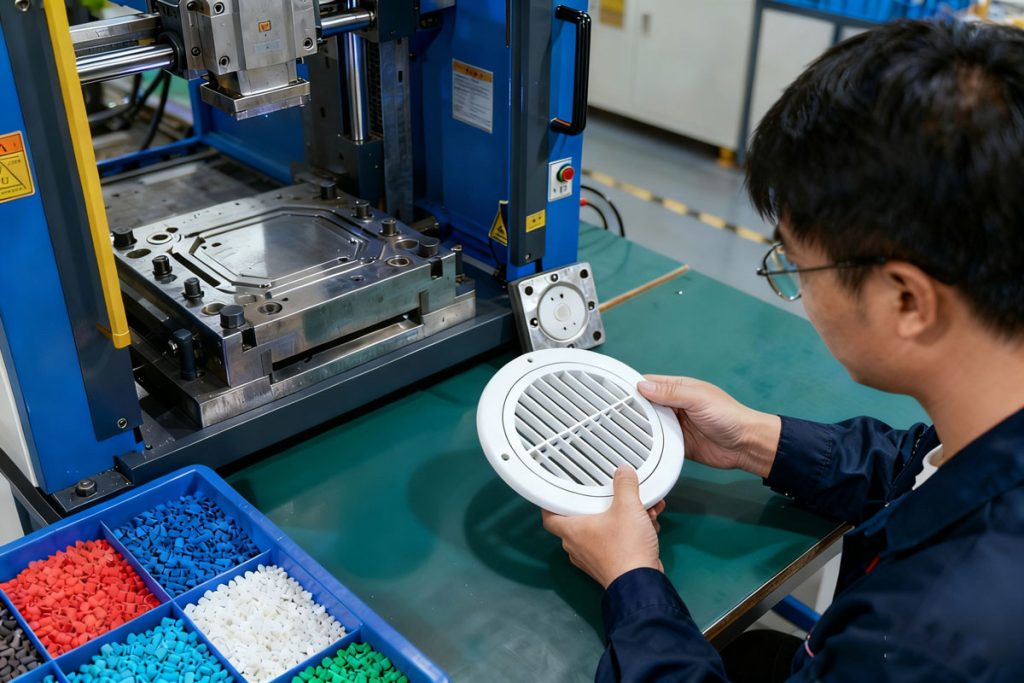

Plastic injection molding is a manufacturing process used to produce parts by injecting molten plastic material into a mold. The mold is then cooled and the solidified part is removed. This technique is highly efficient for creating complex, precise shapes and is widely used in automotive, electronics, and even RV industries. For RV air vents, plastic injection molding offers several benefits, including design flexibility, cost-effectiveness, and durability.

The injection molding process is especially valuable for RV manufacturers and customization experts. With the ability to produce high-quality, customized components in a consistent and repeatable manner, this process ensures that each air vent fits seamlessly into the design and functional needs of the motorhome.

How Plastic Injection Molding Benefits Customized Motorhomes’ Air Vents

In RV customization, plastic air vents are a key feature of the vehicle’s interior. The primary role of air vents is to direct airflow, ensuring that the climate control system works efficiently. However, beyond their basic function, air vents also contribute to the overall aesthetics and comfort of the motorhome. By using plastic injection molding, RV manufacturers and customizers can achieve:

- Precision and Consistency: Plastic injection molding allows for the creation of air vents with intricate designs, ensuring that each vent is made to the same high standard. This consistency is important for both form and function, as vents need to fit seamlessly into the dashboard or ceiling.

- Customization: With this molding process, you can design air vents that fit your unique RV style. From the shape and size to the color and finish, plastic injection molding offers high levels of design flexibility to match your custom motorhome theme.

- Durability: RVs are exposed to a variety of environmental conditions, including sunlight, moisture, and extreme temperatures. Plastic injection molding uses materials like polypropylene (PP) and acrylonitrile butadiene styrene (ABS), which are known for their strength, resistance to heat, and ability to withstand wear and tear, making them ideal for long-term use in motorhomes.

- Cost-Effectiveness: The high-volume production capabilities of plastic injection molding make it a cost-effective solution for manufacturing air vents. This allows for the production of durable and customizable parts without breaking the budget.

The Role of Prototype Manufacturing in RV Air Vent Customization

Before mass-producing air vents for a customized motorhome, prototype manufacturing is essential. Prototyping allows you to test the design and functionality of the air vents to ensure they meet the desired specifications. This phase of production involves the following steps:

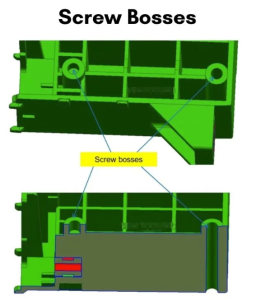

- Design and Engineering: Using computer-aided design (CAD) software, the air vent’s design is created, taking into account factors such as airflow dynamics, material choice, and ease of installation.

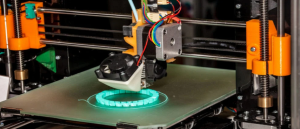

- Prototype Fabrication: A prototype is then created using plastic injection molding techniques to give a physical representation of the final product. This prototype allows for testing and refinement before mass production begins.

- Functionality Testing: The prototype is tested to ensure that it functions properly within the RV’s air conditioning system. This includes checking airflow, ease of adjustment, and durability under typical usage conditions.

- Design Refinement: Based on testing feedback, adjustments can be made to the design of the air vent to ensure it meets all functional and aesthetic requirements.

How Plastic Injection Molding Enhances Air Vent Aesthetics in Customized Motorhomes

When customizing your motorhome, the air vents play a more significant role than just functionality. Air vents, like other interior features, contribute to the visual appeal of the RV. Here’s how plastic injection molding enhances air vent aesthetics:

- Smooth Finish and Custom Color Options: Plastic injection molding can be used to achieve smooth, flawless finishes on air vents. Additionally, custom colors can be applied, allowing the vents to match the interior design of your motorhome. Whether you prefer a glossy black, matte finish, or even a metallic hue, plastic injection molding can bring your vision to life.

- Design Versatility: The complexity of the designs is virtually limitless with plastic injection molding. From sleek, modern air vents to more traditional, textured options, this process can produce various styles to suit your RV’s unique look.

- Integration with Other Features: In custom motorhomes, air vents can be seamlessly integrated with other features, such as control knobs, light fixtures, and entertainment systems. The ability to mold complex components means that vents can be designed to align perfectly with these other elements.

FAQs:

- How long do plastic injection molded air vents last in my RV?

Plastic injection molded air vents made from high-quality materials like ABS or polypropylene are built to last for many years. These materials are resistant to UV rays, heat, and moisture, which makes them ideal for automotive and RV applications. - Can I customize the air vents in my RV?

Yes! Using plastic injection molding, RV manufacturers and customization services can create air vents that are tailored to your specific design preferences. From the shape and size to the color and finish, customization options are endless. - How do I ensure the right fit for my RV air vents?

When choosing customized air vents for your RV, ensure that the dimensions and mounting system match your vehicle’s existing air conditioning system. Prototype testing is also essential to ensure a perfect fit before mass production. - What are the main benefits of choosing plastic injection molding for air vents?

The key benefits of using plastic injection molding for RV air vents include design flexibility, cost-efficiency, durability, and precise production, all of which contribute to a high-quality, long-lasting air vent system.

Conclusion:

Plastic injection molding plays a crucial role in the customization of RV air vents. By offering the ability to produce high-quality, durable, and aesthetically pleasing parts, this manufacturing technique has become a popular choice for RV owners looking to enhance their motorhome’s interior. Whether you are interested in customizing the air vents for functional or design reasons, plastic injection molding ensures you get the perfect balance of performance and style. If you’re ready to upgrade your RV’s air vent system, consider working with a manufacturer that specializes in custom plastic injection molding for the best results.