Introduction to Low-Volume Injection Molding

In the world of plastic manufacturing, small-scale injection molding is an increasingly popular choice for businesses seeking a balance between production costs, speed, and flexibility. Low-volume plastic injection molding (Low-Volume Plastic Injection Molding) refers to the production of smaller quantities of plastic parts, typically ranging from a few dozen to several thousand units. This method is ideal for projects that require fewer parts but still demand high precision and quality.

In this article, we will explore what small injection molding is, its working principles, the benefits it offers, and how it is applied in various industries. Additionally, we’ll present a real-world case study showcasing how low-volume injection molding is used in the consumer product sector.

What is Low-Volume Injection Molding?

Low-Volume Injection Molding is a manufacturing process where plastic is injected into a mold to create parts in smaller quantities than the typical large-scale injection molding. While traditional injection molding processes are designed for mass production, low-volume molding is used when fewer parts are required. This is especially beneficial in prototyping, custom parts, or testing market demand before committing to mass production.

This method involves using simpler molds that are less expensive to produce, making it an ideal option for companies that need a limited number of parts at a lower upfront cost. The production time for low-volume injection molding is also significantly faster than large-scale molding, making it an attractive option for time-sensitive projects.

Working Principle of Low-Volume Injection Molding

The core process of small-scale injection molding follows the same basic principles as traditional injection molding:

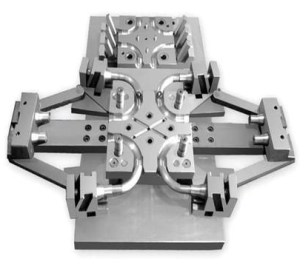

- Mold Design and Fabrication:

Molds are designed based on the specific shape and material requirements of the part. Unlike mass production molds, those used for low-volume injection molding can be simpler and made from less expensive materials. - Heating and Melting Plastic:

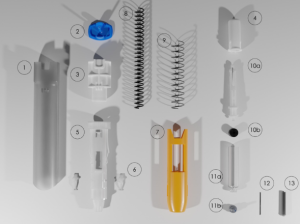

Plastic pellets are heated in an injection molding machine until they become molten and can flow easily into the mold. - Injection into the Mold:

The molten plastic is injected under pressure into the mold cavity. The mold’s design determines the final shape of the part. - Cooling and Solidification:

The plastic is cooled quickly within the mold, solidifying into the final shape. - Demolding and Finishing:

After cooling, the molded parts are removed from the mold and may undergo additional finishing processes such as trimming, surface cleaning, and quality checks.

The simplicity and cost-efficiency of the molds used in low-volume injection molding make this method well-suited for customized or prototype parts that don’t require mass production.

Benefits of Low-Volume Injection Molding

- Cost-Effective Production:

One of the most significant benefits of small injection molding is its cost-effectiveness. Since the molds are less complex and require less expensive materials, the initial investment is lower compared to large-scale production. Additionally, low-volume production reduces the risk of overproduction, making it a suitable solution for budget-conscious projects. - Faster Turnaround Time:

Compared to large-scale manufacturing, low-volume injection molding has a faster production cycle. This speed is essential for businesses that need to quickly prototype products, validate designs, or meet tight market deadlines. - Flexibility and Customization:

Small-scale injection molding offers great flexibility in terms of customization. This is particularly important for industries that require unique designs or specific material properties. Whether it’s testing a new design or producing a limited run of a custom product, low-volume molding can meet the needs of these specialized applications. - Low-Risk Testing and Market Validation:

With small batch injection molding, companies can produce small quantities of products to test the market or assess the design’s functionality. This minimizes the risk associated with large-scale manufacturing and allows for adjustments before committing to larger production runs. - High Precision and Quality:

Low-volume injection molding typically uses high-precision molds, ensuring that each part meets tight tolerances. This is especially important for industries like medical devices, automotive parts, and consumer electronics, where accuracy is crucial.

Applications of Low-Volume Injection Molding in Consumer Industries

Low-volume plastic injection molding is widely used across various industries, particularly in applications where flexibility, speed, and customization are needed. Some common areas include:

- Consumer Electronics:

Products such as custom phone cases, headphone shells, and remote control housings can be produced using low-volume injection molding. These parts require precision and a quick turnaround, both of which are achieved through small-scale injection molding. - Household Items:

Plastic components used in home appliances like refrigerator handles, microwave buttons, and vacuum cleaner housings are often produced in small batches to meet specific customer requirements. - Medical Devices:

In the medical field, small-scale injection molding is used to produce parts such as insulin pen components, hearing aid casings, and other specialized equipment, where precision and material integrity are paramount. - Automotive Components:

Small plastic components such as interior trim, dashboard parts, and custom car accessories can be efficiently produced in low quantities to meet demand without incurring the costs of mass production.

Real-World Case Study: Low-Volume Injection Molding for Dinosaur Toy Company in the UK

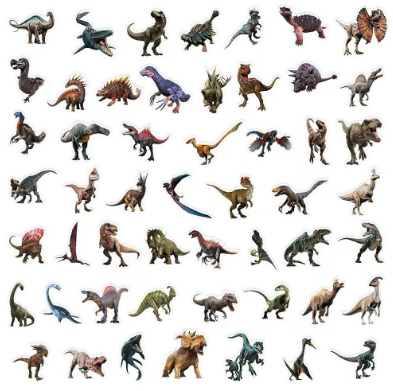

A recent collaboration with a UK-based company, “Dinosaur Toys Ltd,” highlights the efficiency and benefits of low-volume injection molding. Dinosaur Toys needed to produce a limited run of highly detailed, custom plastic dinosaur toys for a new educational product line. Their procurement team approached us with the challenge of meeting strict design requirements, ensuring product durability, and maintaining a fast production timeline to meet the upcoming product launch.

The collaboration involved designing unique molds tailored to their product’s intricate details. The team worked closely with Dinosaur Toys Ltd. to ensure the mold design was optimized for cost-effectiveness while maintaining the highest standards of precision. By utilizing small injection molding, we were able to complete the entire production process in just three weeks, much faster than typical mass production timelines.

The results exceeded expectations. The toy parts were produced in small quantities, with impeccable detail, and met the required safety standards for children’s toys. The company reported significant savings in production costs, as well as a reduced risk of overstocking inventory. Most importantly, the customer was able to assess the market’s response to the toy quickly, allowing for agile production adjustments.

FAQ Section

Q1: What are the cost advantages of low-volume injection molding?

A1: Small-scale injection molding offers cost benefits by reducing the complexity and material costs of molds. It’s a highly efficient option for companies needing custom parts in smaller quantities, without the large upfront costs of mass production.

Q2: How fast can I get my products produced using low-volume injection molding?

A2: The production timeline for small batch injection molding is significantly shorter than for mass production. Typically, prototypes and small runs can be delivered within a few weeks, depending on design complexity.

Q3: Can low-volume injection molding accommodate custom designs?

A3: Yes, one of the primary advantages of low-volume injection molding is its ability to produce highly customized products. Whether it’s a specific part design or using specialized materials, this process is perfect for unique or experimental projects.

Conclusion: The Value of Low-Volume Injection Molding for Custom and Small-Batch Production

Low-volume plastic injection molding is an excellent choice for companies looking to reduce costs, speed up product development, and achieve precise, high-quality results. Whether you need prototypes, limited runs, or custom components, small injection molding can provide a reliable and cost-efficient solution. By leveraging the benefits of this method, businesses can test new designs, validate markets, and meet specific production demands with greater flexibility.

For businesses looking to partner with an experienced manufacturer in small-scale injection molding, please visit our page on Plastic Injection Molding.