Introduction to Low-Volume Injection Molding

In today’s fast-paced manufacturing world, businesses often seek cost-effective and efficient methods for producing small quantities of parts. Small-scale injection molding is a powerful technique designed to meet the needs of projects that require fewer parts, reduced costs, and quicker turnaround times. This manufacturing method has become increasingly popular for prototype development, custom parts, and limited production runs.

In this article, we will explore what low-volume injection molding is, how it works, its benefits, and the diverse applications it has in the consumer industry. Additionally, we will delve into a real-life example, highlighting how this molding method benefited a UK-based automotive parts company.

What is Low-Volume Injection Molding?

Low-Volume Injection Molding (LVIM) is the process of manufacturing plastic parts in small quantities, typically ranging from a few dozen to several thousand pieces. This method is particularly useful when a business needs to produce small batches for prototyping, product testing, or custom orders. It is also ideal for projects with a lower production volume, where the cost of traditional mass production would be prohibitive.

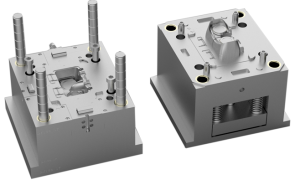

Unlike mass production injection molding, which requires complex molds and long setup times, small injection molding allows businesses to create high-quality parts at a much lower cost. The molds used in LVIM are simpler and cheaper to produce, which makes the process more accessible for smaller companies or those working with tight budgets.

How Does Low-Volume Injection Molding Work?

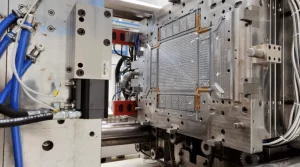

The principle behind low-volume injection molding is similar to traditional injection molding, with a few key differences to accommodate smaller quantities:

- Mold Design and Production:

The first step involves designing a mold based on the product’s requirements. Unlike mass production, where molds are typically made from expensive materials, molds for low-volume injection molding can be simplified, reducing production costs. - Heating and Melting the Material:

Plastic pellets are loaded into an injection machine, where they are heated to their melting point. The molten plastic is then injected into the mold under high pressure. - Injection into the Mold:

The mold is filled with the molten plastic, which takes the shape of the mold cavity. The pressure and speed at which the plastic is injected are carefully controlled to ensure precision and quality. - Cooling and Solidifying:

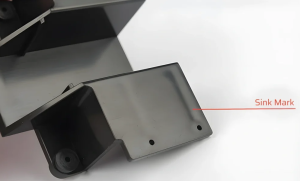

The plastic in the mold is allowed to cool, solidifying into the desired shape. Cooling time is reduced in low-volume molding due to the smaller quantity and simpler design of the molds. - Demolding and Finishing:

Once the plastic has cooled and solidified, the mold is opened, and the parts are removed. These parts are then cleaned and undergo any necessary finishing processes, such as trimming or polishing.

By using simpler molds and producing smaller quantities, low-volume injection molding ensures both cost efficiency and fast production cycles, making it an attractive option for companies with limited production runs.

Key Benefits of Low-Volume Injection Molding

Low-volume injection molding provides a range of benefits for businesses looking to produce small quantities of high-quality plastic parts. These benefits include:

- Cost Efficiency:

One of the major advantages of small-scale injection molding is its cost-effectiveness. The molds used are simpler, which reduces their cost compared to large-scale production molds. This is especially beneficial for businesses with limited budgets or those needing smaller runs of custom parts. - Faster Production and Delivery:

Low-volume molding typically offers faster production times. Since fewer parts are made and the molds are simpler, businesses can expect quicker turnaround times, which is especially useful for product testing and prototype development. - Flexibility in Production:

Small batch injection molding is highly flexible, making it ideal for custom projects, whether it’s a unique product design or a special material requirement. The ability to produce smaller quantities of customized parts allows businesses to adapt quickly to changing market demands. - Reduced Risk:

Low-volume production offers a way to test designs and products before committing to large-scale production. This reduces the risk of mass-producing a product that may not perform well in the market or meet consumer expectations. - High Precision and Quality:

The molds used in low-volume molding are often designed with high precision, which ensures that the final product meets strict quality standards. This is crucial for industries like medical devices, automotive, and electronics, where quality control is paramount.

Application of Low-Volume Injection Molding in the Consumer Industry

Low-volume plastic injection molding is widely used across several consumer industries, offering solutions for companies that require smaller production runs or customized parts. Here are some common applications:

- Consumer Electronics:

Small quantities of customized parts, such as phone cases, headphone shells, or remote control housings, can be produced using small injection molding. This helps manufacturers meet specific market demands without investing in large-scale production. - Automotive Parts:

In the automotive industry, low-volume molding is used to produce specialized parts, such as custom dashboard components or vehicle lighting. It’s also perfect for small aftermarket production runs, where the demand is limited. - Medical Devices:

The medical industry often requires custom, high-precision components in small quantities. Low-volume injection molding helps produce these specialized parts quickly and cost-effectively, ensuring they meet strict regulatory standards. - Home Goods and Appliances:

Low-volume molding can be used for parts in household items such as vacuum cleaners, kitchen gadgets, or furniture components. This process allows manufacturers to produce high-quality parts that cater to niche markets.

Real-World Case Study: Automotive Headlight Covers for a UK-Based Tuning Company

One of our recent collaborations involved a UK-based automotive tuning company, “AutoMods Ltd,” which required small quantities of custom plastic headlight covers for a new product line aimed at car enthusiasts. The company sought a solution to produce these parts in limited quantities, with high precision and a fast turnaround time to meet an upcoming trade show deadline.

Through our small-scale injection molding process, we were able to produce the headlight covers in less than two weeks, ensuring they were delivered on time for the event. The molds used were simple yet highly effective, reducing the overall production costs. The customer was highly satisfied with the finished product, which exceeded their quality expectations. The project not only met the client’s design and functionality requirements but also resulted in significant cost savings compared to traditional mass production methods.

FAQ Section

Q1: How does small-scale injection molding reduce production costs?

A1: Small-scale injection molding reduces costs by using simpler molds that are less expensive to produce and maintain compared to mass production molds. Additionally, smaller production runs reduce material waste and the need for large inventories.

Q2: Can low-volume injection molding be used for custom parts?

A2: Yes, small injection molding is ideal for producing custom parts. The flexibility of the process allows for high precision and customization, making it perfect for unique product designs or limited-edition runs.

Q3: How fast can I get my custom parts produced?

A3: Low-volume injection molding offers faster production times compared to large-scale production. Depending on the complexity of the design, parts can be produced and delivered in a few weeks, which is ideal for rapid prototyping and market testing.

Conclusion: Why Choose Low-Volume Injection Molding?

Low-volume injection molding offers numerous advantages for companies seeking cost-effective, flexible, and high-quality solutions for small-scale production. From quick turnarounds to customization, it provides an efficient manufacturing option for prototype development, custom parts, and niche markets.

If you are looking to produce high-quality custom parts in small quantities, explore our Plastic Injection Molding services and discover how we can support your next project.