Introduction:

Choosing the right air vent for your RV is a key decision when upgrading or maintaining your vehicle’s air conditioning system. Whether you’re looking to enhance the airflow, improve the design, or reduce maintenance, selecting the correct materials and manufacturing techniques will significantly impact the quality and efficiency of your RV’s air vent system. In this article, we’ll dive into the plastic molding techniques, particularly plastic injection molding, and explore how they are used in manufacturing car air conditioning vents. This knowledge will help you make an informed decision for your RV’s needs.

What is Plastic Injection Molding?

Plastic injection molding is a popular manufacturing process where plastic material is melted and injected into a mold cavity to form a specific shape. The process is known for producing precise, high-quality parts with complex geometries at a low cost for high-volume production. For RV owners and automotive manufacturers, this method is especially beneficial for creating durable, lightweight, and cost-effective car air conditioning vents that require specific designs for optimal air distribution.

Why Plastic Injection Molding is Ideal for Car Air Conditioning Vents

Car air conditioning vents play a crucial role in providing efficient airflow while maintaining the aesthetic and functional needs of the vehicle interior. Plastic injection molding provides several benefits in the production of automotive parts like air vents, including:

- Precision and Customization: Injection molding allows for the production of complex parts with exact specifications, ensuring that the vents fit perfectly in the dashboard and deliver optimal airflow.

- Durability and Strength: The materials used in injection molding can be chosen for their resistance to heat, UV rays, and moisture—essential properties for parts that are exposed to extreme conditions like high temperatures or direct sunlight inside an RV or car.

- Cost Efficiency for Mass Production: Injection molding is especially cost-effective when producing large quantities of parts, making it a perfect choice for both manufacturers and consumers looking for affordable, reliable, and high-quality air vents.

Key Factors in Designing Car Air Conditioning Vents

When designing air vents for vehicles, especially RVs, there are several important factors to consider:

- Airflow Efficiency: The design should maximize the flow of cool air while minimizing energy consumption. The orientation and size of the vent blades can significantly affect air distribution.

- Material Selection: For durability, automotive plastic injection molding uses high-performance plastics, such as polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polycarbonate (PC). These materials resist heat, UV degradation, and are lightweight, making them ideal for vehicle interiors.

- Aesthetic Design: The design should also complement the vehicle’s interior. Customized finishes, such as matte or gloss coatings, can be applied to enhance the visual appeal of the vents.

Plastic Injection Molding Process for Automotive Air Vents

The process of producing car air conditioning vents typically involves several key steps:

- Prototype Development: This initial phase involves creating a prototype of the air vent to test its design and functionality. Prototypes are made using quick-turnaround injection molding to ensure a functional and aesthetic fit.

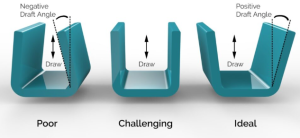

- Mold Design and Fabrication: The next step is to design a mold for mass production. The mold is meticulously crafted using precision machinery, ensuring it meets the exact specifications required for the air vent.

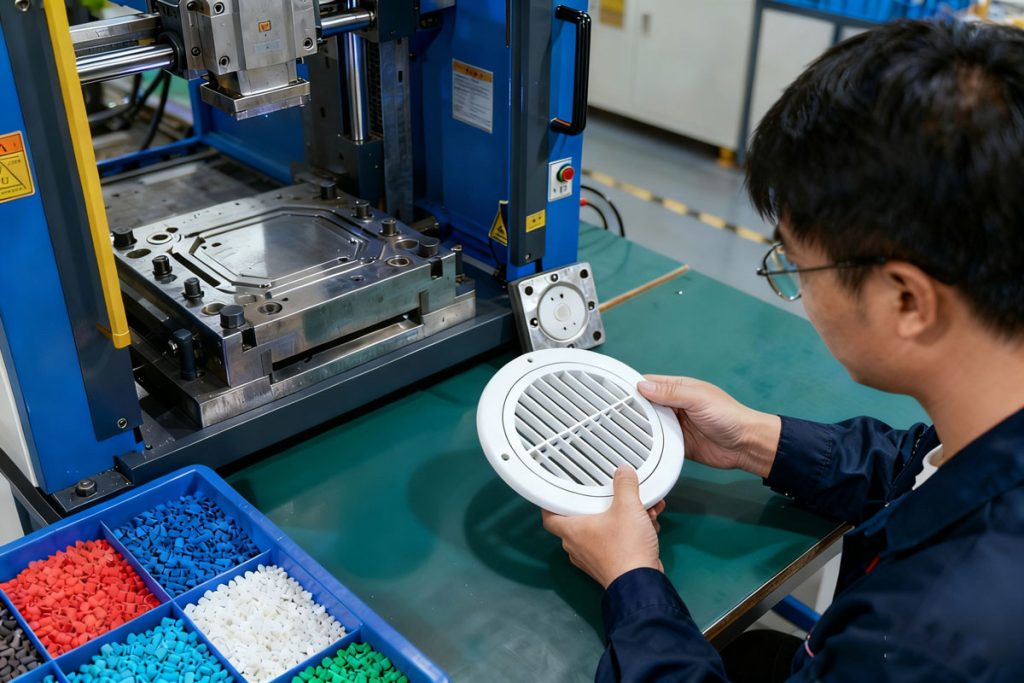

- Injection Molding Production: Once the mold is ready, plastic pellets are melted and injected into the mold under high pressure. The mold is then cooled, and the finished air vent is removed.

- Post-Processing and Quality Control: The air vent is carefully inspected for defects, and any excess plastic is trimmed off. It is then tested for functionality and durability.

How to Choose the Right Air Vent for Your RV?

When selecting an air vent for your RV, keep the following in mind:

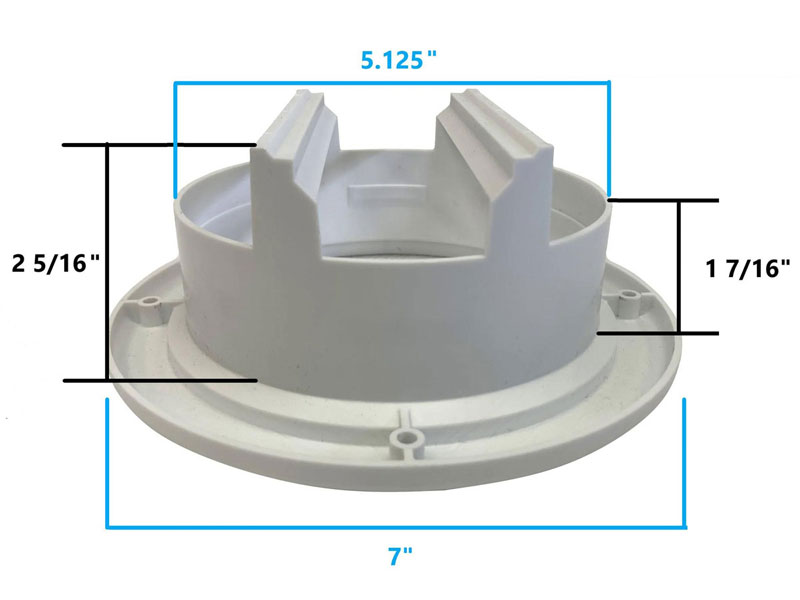

- Compatibility with Your RV’s AC System: Ensure that the air vent fits seamlessly into the existing air conditioning system. Check the dimensions and ensure the receiver size and mounting style match.

- Material Durability: Choose vents made from high-quality materials, such as those produced through plastic injection molding, to ensure they can withstand the rigors of travel, extreme temperatures, and humidity inside your RV.

- Ease of Adjustment: The design of the vent blades should allow for easy adjustment of the airflow direction. Some air vents feature flexible blades or adjustable louvers for customized airflow.

- Aesthetic Considerations: If the visual appeal of your RV interior is important, consider choosing vents that complement the overall interior design. Many injection-molded vents are available in various finishes and colors.

FAQs:

- What is the lifespan of plastic injection molded air vents?

Injection molded air vents can last for many years when made from high-quality materials like ABS or polypropylene. These materials are resistant to heat, UV rays, and wear, making them durable and long-lasting. - Can I customize my RV air vents using plastic injection molding?

Yes, plastic injection molding allows for high customization in terms of shape, size, material, and color. This makes it easy to tailor the air vent to your specific RV interior design and functional needs. - How do I maintain my RV air vents?

Regular cleaning is important to maintain airflow efficiency. Simply wipe the vents with a damp cloth to remove dust and debris. Additionally, inspect the vents for cracks or signs of wear over time.

Conclusion:

Selecting the right air vent for your RV can dramatically improve both comfort and energy efficiency. Plastic injection molding offers numerous advantages, from precise design to high durability, ensuring that the air vents can withstand the unique demands of automotive environments. Whether you’re looking for custom designs or mass-produced solutions, injection molding provides a reliable and cost-effective way to meet your needs. Contact a trusted manufacturer to explore the best air vent options for your RV, and start enjoying better airflow today!