Plastic Prototype Manufacturing – Process, Materials, and Cost

In today’s fast-paced manufacturing world, plastic prototype manufacturing plays a vital role in helping companies turn their ideas into tangible products. Whether you are developing a new consumer product, an automotive component, or a medical device, prototypes bridge the gap between concept and mass production. They allow designers, engineers, and procurement teams to test functionality, verify form, and refine designs before investing in full-scale tooling.

In this guide, we’ll explore the process, materials, and cost factors of plastic prototype manufacturing — and show how working with a professional mold and injection molding company like DTG ensures efficiency, precision, and cost control.

What Is Plastic Prototype Manufacturing?

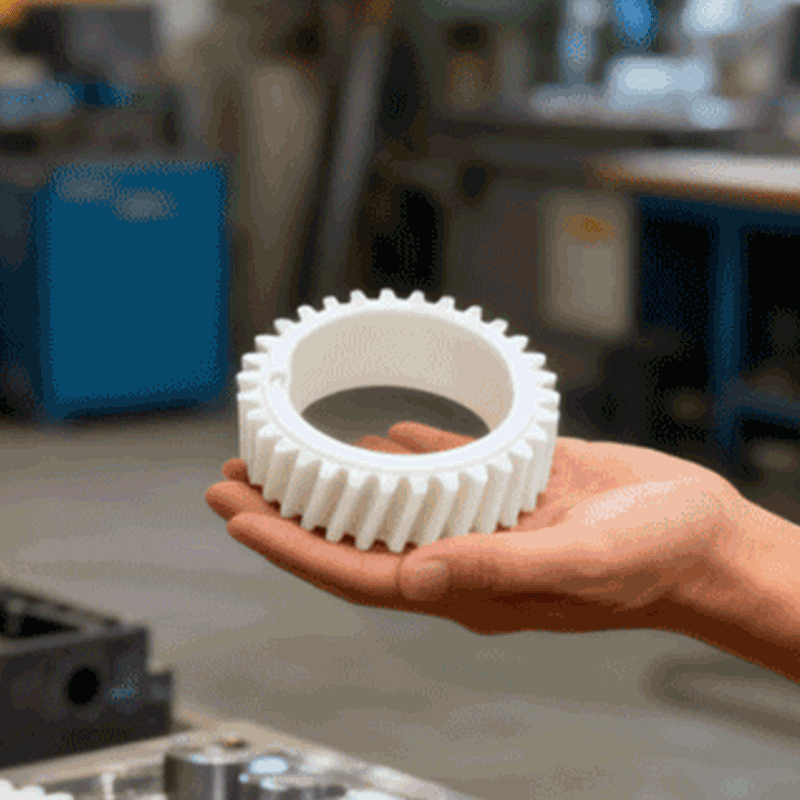

Plastic prototype manufacturing refers to the process of creating a sample or trial version of a plastic part or product before mass production. This prototype serves as a functional and aesthetic model that helps validate design, material choice, and production methods.

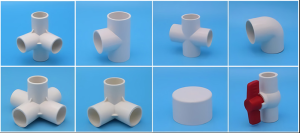

Prototypes can range from simple visual models to fully functional units capable of mechanical testing. Depending on the project’s goals, they may be made using CNC machining, 3D printing, or injection molding.

The Process of Plastic Prototype Manufacturing

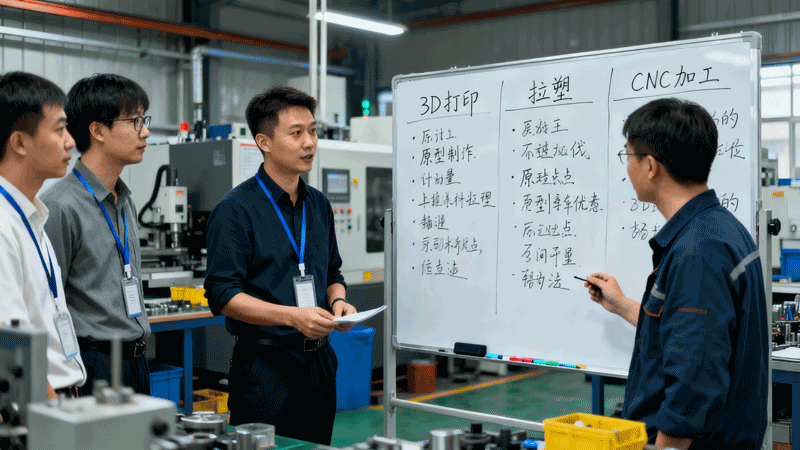

The plastic prototyping process generally includes six main stages.

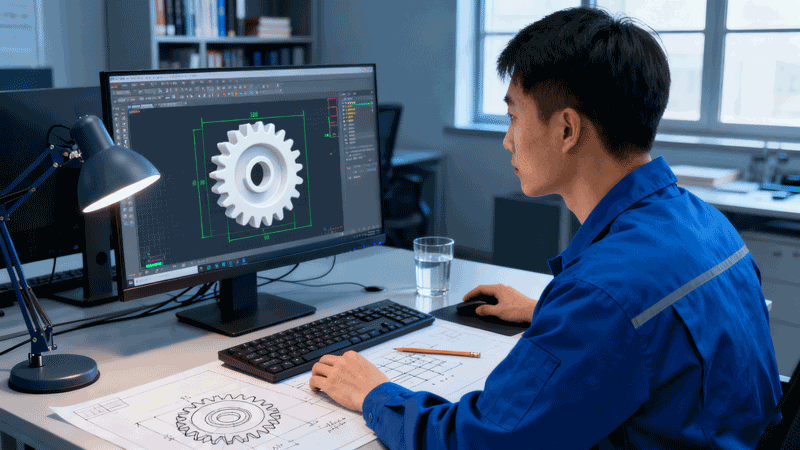

- Concept & Design

The process starts with the creation of a 3D CAD model, which defines dimensions, tolerances, and assembly interfaces. At this stage, design engineers evaluate manufacturability and suggest improvements for tooling and molding feasibility. - Material Selection

Choosing the right material is critical. Plastic prototypes can be made using ABS, PC, PA, PMMA, or other resins that mimic the mechanical and visual properties of the final part. The selected material affects the prototype’s strength, flexibility, and finish. - Prototyping Method Selection

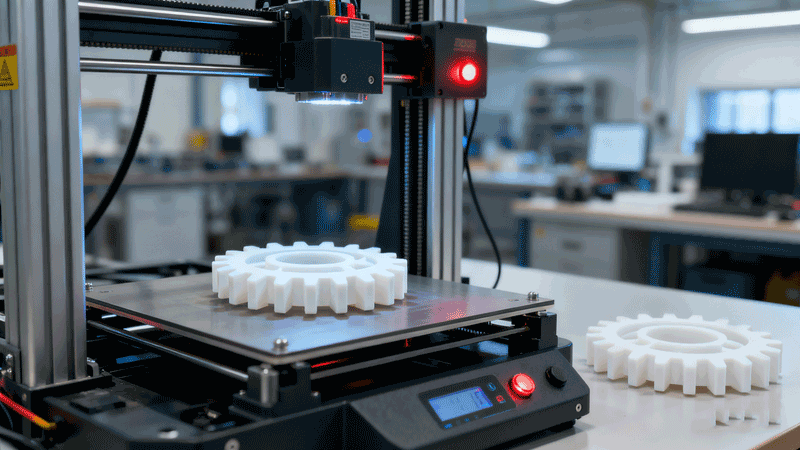

Based on design complexity, production quantity, and required precision, one or more of the following methods may be used:- 3D Printing (SLA, SLS, FDM) – Ideal for quick visual models and low-cost prototypes.

- CNC Machining – Offers high precision and surface finish suitable for engineering verification.

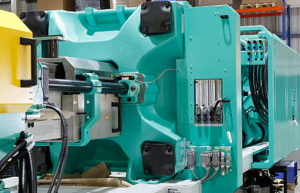

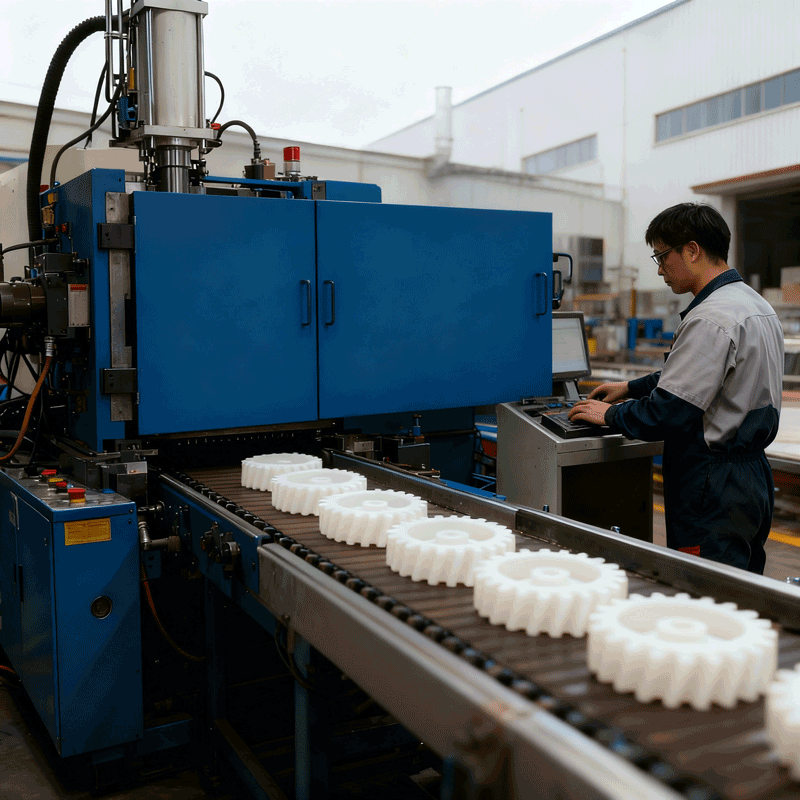

- Injection Molding – Provides the closest representation to mass production results, including identical materials and finishes.

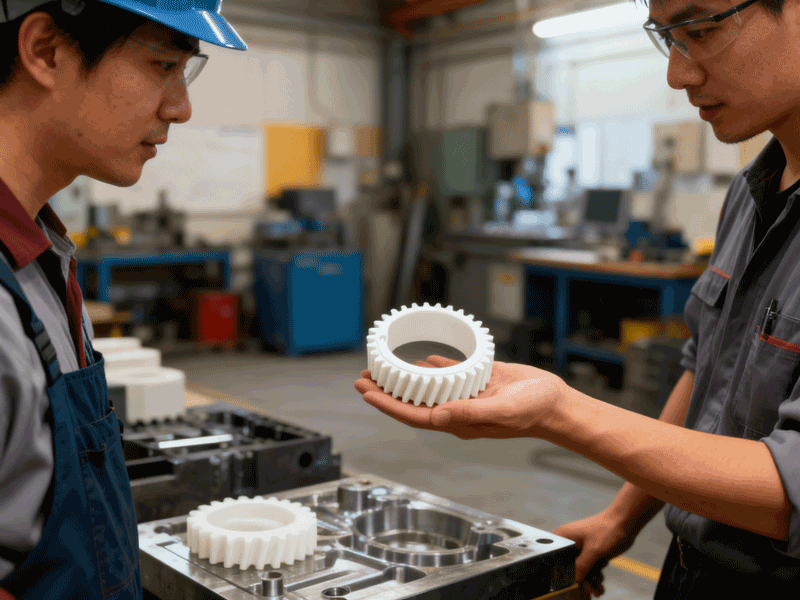

- Prototype Fabrication

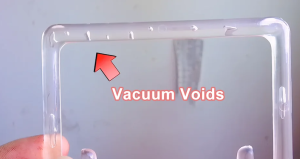

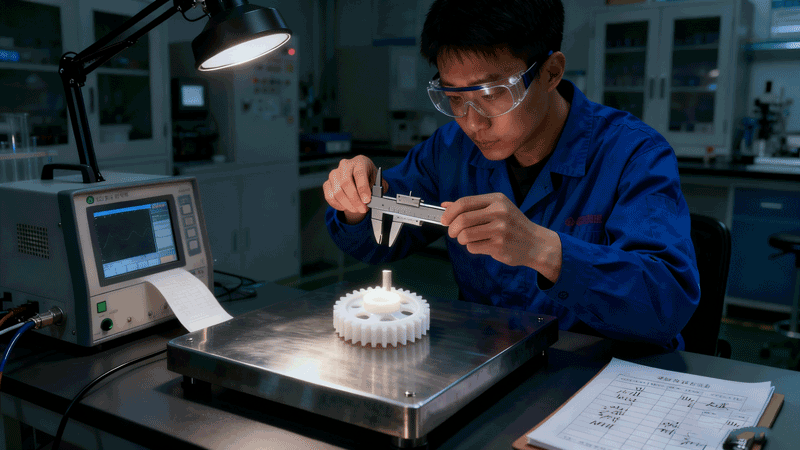

The design is fabricated using the chosen method. During this step, multiple iterations may be created to evaluate different versions, tolerances, or design modifications. - Testing & Validation

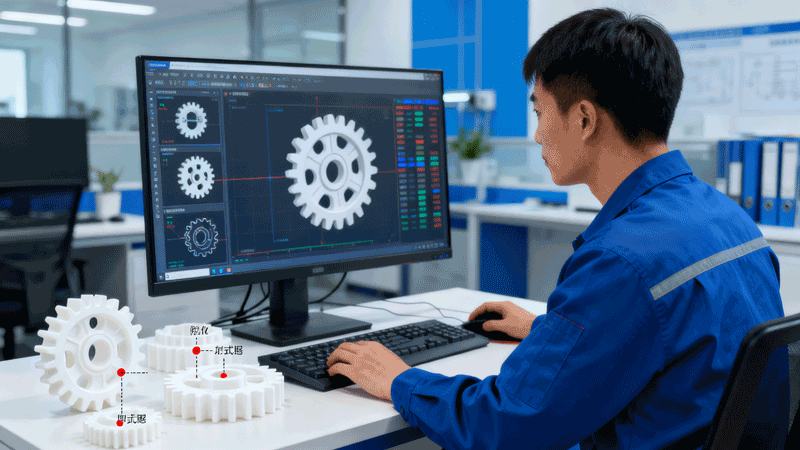

The prototype undergoes physical testing to verify performance, assembly compatibility, and durability. This helps identify any issues that could affect large-scale production. - Design Refinement

Feedback from testing is used to adjust the CAD model, refine geometry, and improve manufacturability. Once finalized, the design is ready for mold manufacturing and mass production.

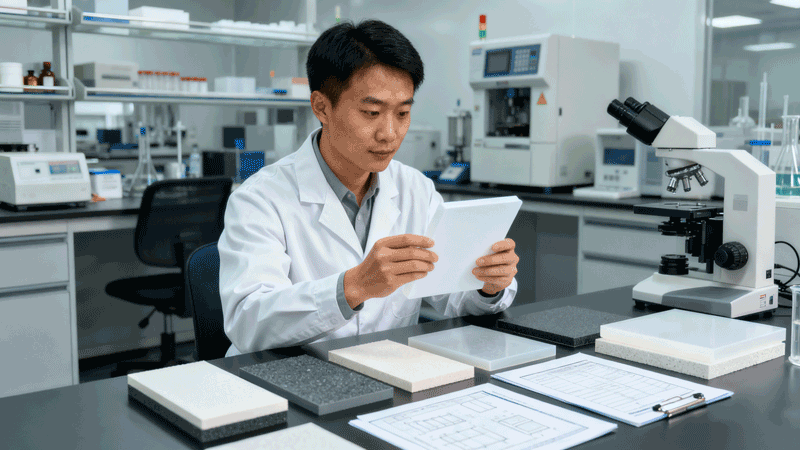

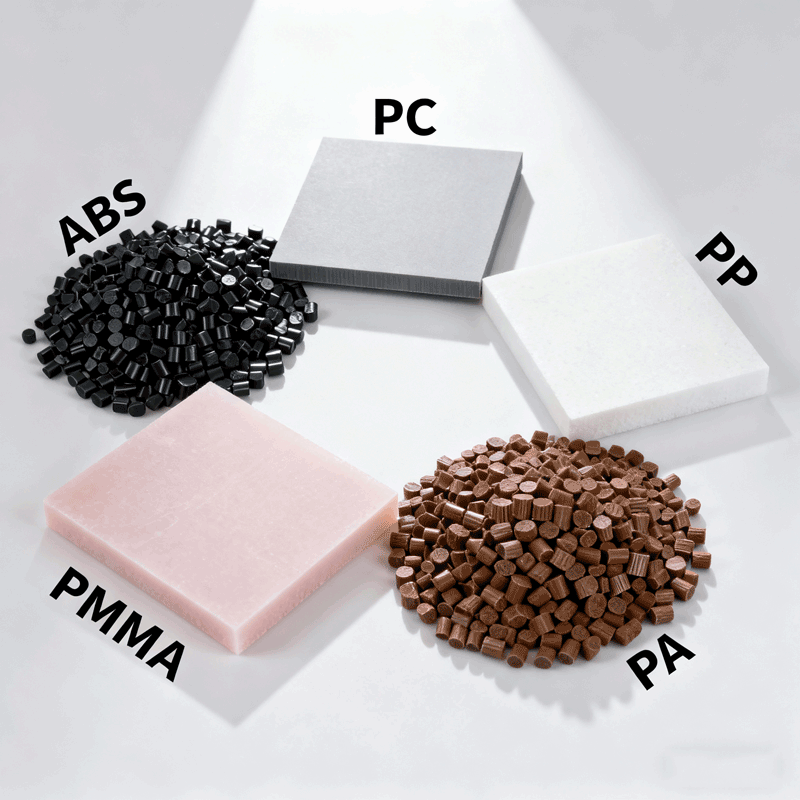

Common Materials Used in Plastic Prototypes

Selecting the right material ensures your prototype behaves similarly to the final production part. Below are commonly used materials in plastic prototype manufacturing:

| Material | Key Properties | Common Applications |

|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Impact-resistant, easily machined, cost-effective | Consumer electronics, enclosures |

| PC (Polycarbonate) | Transparent, heat-resistant, high strength | Automotive lenses, medical housings |

| PA (Nylon) | Wear-resistant, flexible, good chemical resistance | Gears, bushings, mechanical parts |

| PMMA (Acrylic) | High transparency, glossy finish, good optical clarity | Lighting components, displays |

| PP (Polypropylene) | Lightweight, fatigue-resistant, low moisture absorption | Packaging, caps, automotive parts |

Choosing between these materials depends on several factors: mechanical requirements, cosmetic preferences, production scale, and budget.

Cost and Lead Time in Plastic Prototype Manufacturing

One of the most common questions from procurement teams is: “How much does plastic prototype manufacturing cost?” The answer depends on multiple variables, including design complexity, material type, and production method.

1. Prototyping Method

- 3D Printing: $50–$500 per part, lead time 1–3 days.

- CNC Machining: $200–$1,500 per part, lead time 5–10 days.

- Injection Molding: $1,000–$10,000 for mold setup, $2–$50 per part depending on volume.

2. Material Choice

Premium materials like PC or reinforced nylon cost more than standard ABS or PP.

3. Quantity

Low-volume runs are more expensive per piece due to setup and programming costs.

4. Tolerance & Finish Requirements

Tighter tolerances and polished or textured finishes increase labor and tooling costs.

5. Location and Service Provider

Partnering with a professional manufacturer like DTG, which integrates design, mold-making, and production, can reduce overall cost and turnaround time by streamlining the process.

Why Choose DTG for Plastic Prototype Manufacturing

At DTG, we combine mold manufacturing, plastic injection molding, and prototype development to provide a seamless solution from concept to mass production. Our in-house engineers and advanced equipment ensure precision, speed, and quality in every project.

- End-to-End Service: From CAD design to tooling and production.

- Fast Turnaround: Rapid prototyping within days, not weeks.

- High Precision: CNC-machined molds and tight tolerance control.

- Material Expertise: Wide range of engineering plastics and finishes.

- Flexible Production: Low-volume runs or high-volume manufacturing.

Our clients span automotive, medical, consumer electronics, and industrial equipment sectors. Whether you need a single prototype or a full-scale molding solution, DTG ensures every step meets your quality and timeline expectations.

FAQs About Plastic Prototype Manufacturing

Q1: What is the typical lead time for a plastic prototype?

Depending on the complexity and method, prototypes can be produced within 2 to 10 days. 3D printing offers the fastest turnaround, while injection-molded prototypes may require longer due to tooling.

Q2: How do I choose the right material for my prototype?

Consider the part’s intended use — if it needs heat resistance, choose PC; for flexibility, use PP; for general durability and affordability, ABS is ideal. Our engineers can help you select the most cost-effective option.

Q3: Can I use prototype molds for small production runs?

Yes. Prototype molds (also called bridge molds) are perfect for low-volume production — typically up to a few thousand parts — providing a balance between cost and production realism.

Q4: How can I reduce prototype manufacturing costs?

Simplify design features, use standard materials, and work with an integrated provider like DTG that handles both prototyping and mass production under one roof.

Conclusion: Turning Ideas into Plastic Reality

Plastic prototype manufacturing is the foundation of successful product development. It minimizes risks, speeds up time-to-market, and ensures that the final product performs as intended.

By partnering with DTG, you gain access to professional mold and injection molding expertise, advanced equipment, and a team that understands the balance between cost, quality, and delivery. From rapid prototyping to mass production, DTG provides end-to-end solutions tailored to your business needs.

Call to Action:

📩 Ready to bring your concept to life?

Contact DTG today for a customized quote on plastic prototype manufacturing or full-scale injection molding services. Let’s turn your design into a real, functional product with precision and efficiency.