In the fast-paced world of product development, an idea is only as good as its execution. Before committing to the high costs of mass production, businesses need a tangible, functional way to test, validate, and refine their designs. This is where prototype manufacturing becomes indispensable. It is the critical bridge between a digital concept and a market-ready product.

So, what exactly is it? Prototype manufacturing is the process of creating a preliminary model or sample of a product to evaluate its design, functionality, and production feasibility. These early-stage models can range from simple, non-functional visual mock-ups to fully functional units that are identical to the final product.

Understanding how prototype manufacturing works is crucial for anyone involved in bringing a new product to life. This guide will walk you through the process, its applications, and the undeniable advantages it offers.

The Prototype Manufacturing Process: A Step-by-Step Guide

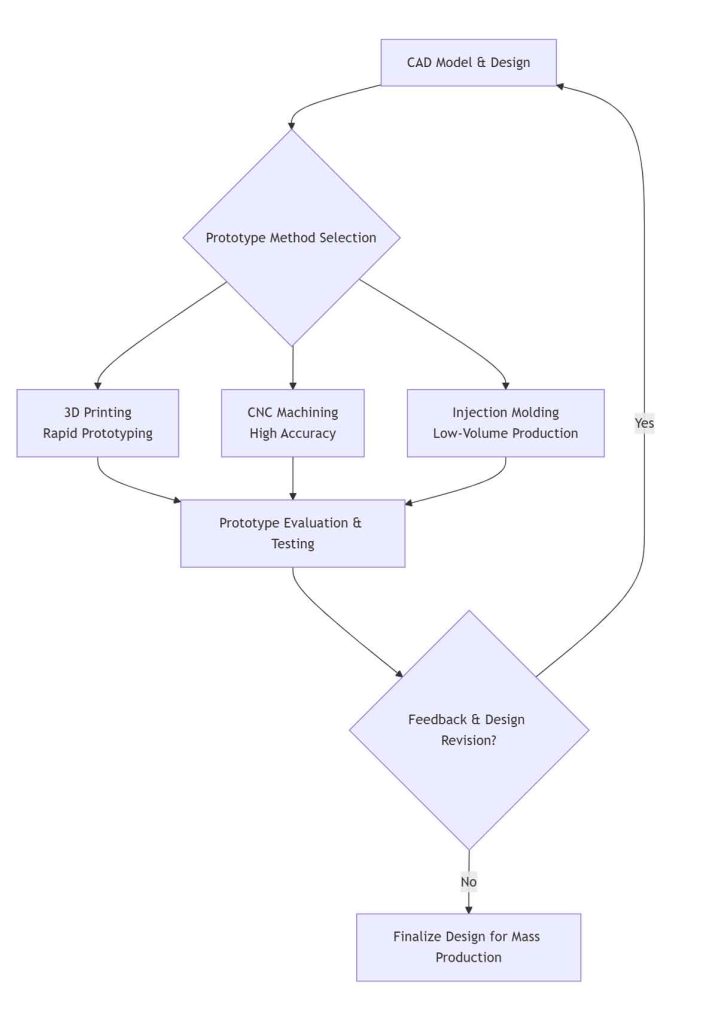

The journey from a CAD file to a physical prototype is methodical and iterative. While the specifics can vary based on the project, the core workflow generally follows these steps:

1. Concept and Design (CAD Modeling):

It all starts with an idea. Engineers and designers use Computer-Aided Design (CAD) software to create a detailed 3D model of the part. This digital blueprint defines every dimension, feature, and tolerance. A well-crafted CAD model is the foundation for everything that follows.

2. Method Selection:

Once the design is finalized, the most suitable prototype manufacturing method is chosen. This decision is based on the prototype’s purpose (e.g., visual check, functional test), required material, lead time, and budget. Key methods include:

- 3D Printing (Additive Manufacturing): Ideal for rapid turnaround of complex geometries. It’s perfect for form and fit testing, concept models, and even some functional prototypes.

- CNC Machining (Subtractive Manufacturing): Uses precision tools to carve a solid block of material (like aluminum or ABS plastic) into the desired shape. It produces high-strength, durable prototypes with excellent surface finish, suitable for functional testing and pre-production validation.

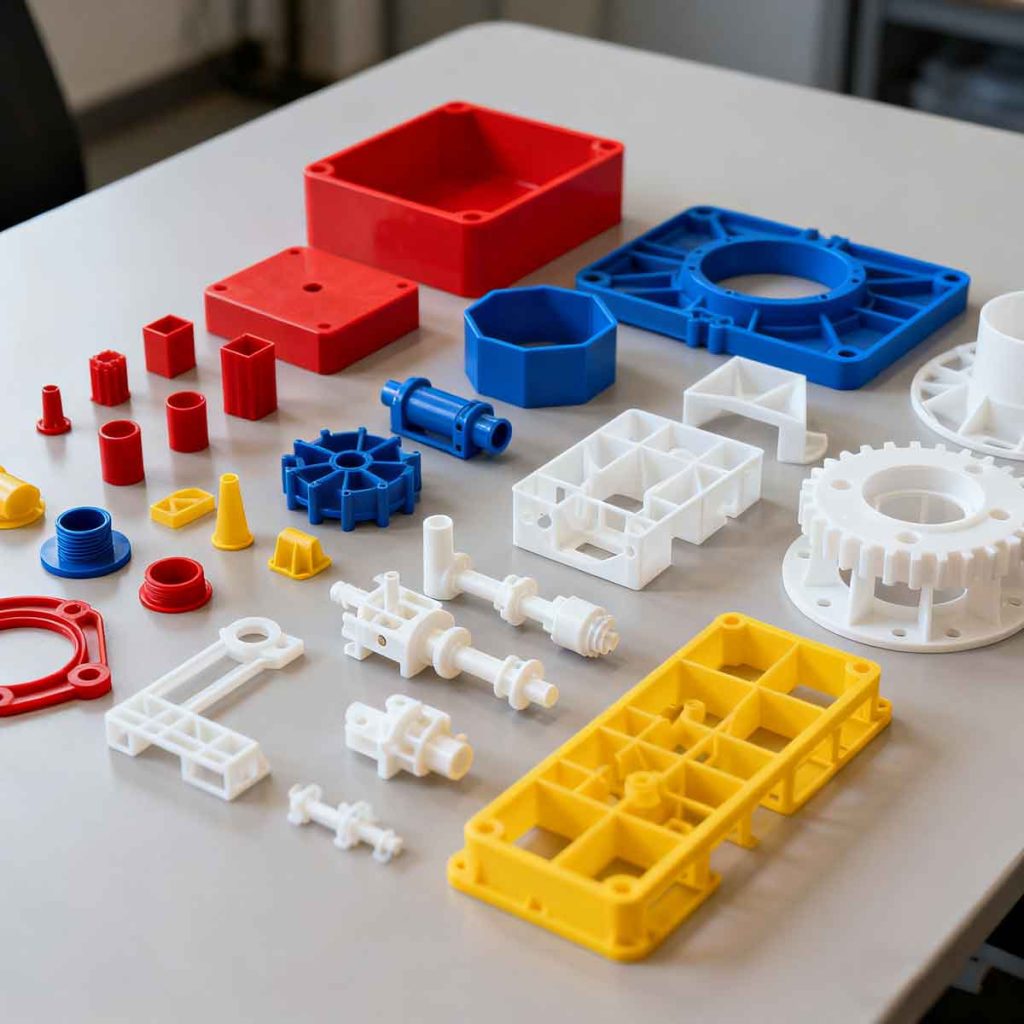

- Rapid Tooling & Low-Volume Injection Molding: This is where our expertise at DTG shines. For plastic parts, we create a simplified, cost-effective mold. This allows for the production of 10s to 1000s of prototype parts using the same manufacturing process as mass production (injection molding), ensuring they are truly representative of the final product.

The following chart illustrates this streamlined, iterative process:

3. Prototyping and Evaluation:

The physical prototype is built using the selected method. The team then rigorously evaluates it for:

- Form and Fit: Does it look and feel right? Does it assemble with other components?

- Function: Does it work as intended? Can it withstand real-world conditions?

- Manufacturability: Are there any design flaws that would make mass production difficult or expensive?

4. Feedback and Iteration:

The insights gained from testing are fed back into the CAD model. The design is refined, and a new prototype may be created to validate the changes. This loop continues until the design is perfected.

Key Applications of Prototype Manufacturing

Prototypes are not just for engineers; they serve a vital role across the entire product development lifecycle.

- Design and Concept Validation: Quickly bring ideas to life to visualize the product and gather early feedback from stakeholders.

- Functional Testing: Test the prototype under real-world stresses, temperatures, and usage scenarios to identify weaknesses before full-scale production.

- Market Research and Funding: A working prototype is a powerful tool for demonstrating your product to potential investors, partners, or at trade shows to gauge market interest.

- Regulatory Approval: Many industries (medical, automotive, aerospace) require physical prototypes for safety and compliance certification.

- Production Validation: Low-volume injection molded prototypes help verify that the final mass-production tooling and process will yield high-quality parts.

The Critical Advantages of Professional Prototype Manufacturing

Investing in a professional prototype manufacturing process yields substantial returns, far outweighing the initial cost.

- De-risk Mass Production: Identify and solve design flaws early, preventing costly mold modifications and production delays down the line.

- Accelerate Time-to-Market: By streamlining the design and testing phases, you can get your product to market faster than your competitors.

- Reduce Overall Costs: Catching a $1,000 problem during prototyping can save you from a $100,000 disaster during mass production.

- Enhance Product Quality: Iterative testing and refinement lead to a superior, more reliable, and better-designed final product.

- Improve Communication: A physical model eliminates ambiguity, ensuring everyone—from designers to marketers—is aligned on the final product vision.

FAQ: Your Prototype Manufacturing Questions Answered

Q1: What is the typical lead time for a prototype?

Lead times can vary dramatically based on complexity and method. Simple 3D printed parts can be ready in 1-3 days, while CNC machined or low-volume molded prototypes may take 1-4 weeks. At DTG, we specialize in rapid turnaround without compromising quality.

Q2: How do I choose between 3D printing and CNC machining for my prototype?

The choice depends on your goal. Use 3D Printing for speed, complex geometries, and lower costs for form/fit models. Choose CNC Machining for high strength, tight tolerances, and testing with end-use materials. For plastic parts that need to be identical to the mass-produced version, low-volume injection molding is the gold standard.

Q3: Can you create a prototype that uses the same material as our final production part?

Absolutely. This is a major advantage of working with a full-service manufacturer like DTG. Whether you need a specific engineering-grade plastic for injection molding or a particular metal alloy for CNC machining, we can source the material to ensure your prototype performs like the real thing.

Q4: My design is complex. Can you help with design for manufacturability (DFM) analysis?

Yes, and we highly recommend it. Our engineering team provides comprehensive DFM analysis as part of our prototype manufacturing service. We identify potential production issues, suggest design optimizations for cost and performance, and work with you to ensure your design is not only innovative but also manufacturable.

Conclusion: From Prototype to Production with Confidence

Prototype manufacturing is not an expense; it’s a strategic investment in your product’s success. It de-risks development, saves money in the long run, and ultimately results in a better product for your customers.

As you move from a validated prototype to full-scale production, partnering with a manufacturer that can seamlessly scale with you is vital. At DTG, we specialize in bridging that gap. Our expertise in custom mold and injection molding production means your project can transition smoothly from prototype development to low-volume injection molding and finally to high-volume mass production injection molding, all under one roof.

Ready to bring your idea to life? Contact us today for a free project review and quotation. Let our team of experts help you navigate the prototype manufacturing process and build a better product, faster.