For procurement professionals in the automotive industry, selecting a Plastic Injection Molding partner is a critical decision that impacts your supply chain’s reliability, cost-efficiency, and product quality. Beyond just finding a supplier, you need a strategic partner who guarantees quality assurance (meeting strict EU/US standards), stable delivery, total cost advantage, provides verified case studies, and ensures flawless communication in English. This guide delves into how DTG’s comprehensive custom mold and injection molding production services are designed to meet these exacting procurement criteria, especially for plastic injection molding automotive parts.

The Critical Role of Plastic Injection Molding in Modern Automotive Design

The automotive industry’s shift towards plastics is driven by undeniable benefits. The average plastic content per vehicle has skyrocketed from 50 kg in the 1970s to approximately 150 kg today, a trend that continues to grow. This is largely due to the advantages offered by advanced Plastic Injection Molding processes. These include significant weight reduction for better fuel efficiency, superior corrosion resistance leading to longer part life, and unparalleled design freedom for complex, integrated components. For procurement, this translates into sourcing parts that are not only cost-effective to produce but also contribute to the vehicle’s overall performance, safety, and aesthetic appeal, all while complying with increasingly stringent global environmental and safety regulations.

Achieving Total Cost Advantage in Your Supply Chain

While unit price is a factor, strategic procurement focuses on the Total Cost of Ownership. A lower initial part cost can be misleading if it leads to tooling failures, production delays, or quality rejections. Our approach to Plastic Injection Molding is built on delivering long-term value. We achieve this through robust mold engineering that maximizes longevity, even for high-volume runs, and process optimization that minimizes scrap rates and secondary operations. Furthermore, our project management efficiency reduces your administrative overhead. By ensuring consistent quality and on-time delivery, we eliminate the hidden costs of line stoppages and air freight emergencies, providing you with a stable, predictable, and ultimately more cost-effective supply chain.

Quality Assured: Compliance with EU and US Automotive Standards

Quality in the automotive sector is non-negotiable. Parts must comply with rigorous international standards for safety, performance, and environmental impact (such as RoHS and REACH). Our quality management system is designed from the ground up to meet these demands. We implement rigorous First Article Inspection (FAI), utilize Statistical Process Control (SPC) during production, and provide complete documentation packages for full traceability. Our material expertise ensures that every plastic injection molding automotive part—whether an interior trim made from scratch-resistant PP or an under-hood component from heat-stabilized nylon—is produced to specification, batch after batch.

Case Study: Delivering a Complex HVAC Component for a Swedish OEM

Country: Sweden

Company: A Swedish manufacturer of premium commercial vehicles (identity protected under NDA).

Procurement Need: The client required a complex, low-volume HVAC (Heating, Ventilation, and Air Conditioning) duct for a new electric bus model. The part needed to withstand constant vibration, exposure to varying temperatures, and resist specific automotive fluids. A Class-A surface finish was also required for aesthetic reasons. The project was on an accelerated timeline to align with the vehicle’s launch.

The Solution & Outcome: DTG was tasked with the design for manufacturability, mold creation, and production of this component using our Plastic Injection Molding services. We developed a multi-cavity aluminum mold and selected a durable, glass-filled polypropylene material.

- Quality Exceeded Expectations: The first articles submitted passed all performance and durability tests on the first attempt. The client’s engineering team specifically commended the flawless surface finish, which was free from the sink marks and flow lines that often plague complex Plastic Injection Molding projects.

- Delivery Timeline Shortened: Through efficient project scheduling and parallel processing, we delivered the initial production batch of 1,000 parts ten days ahead of the contracted schedule.

- Client Endorsement: The Procurement Director from the Swedish company stated: “DTG demonstrated a profound understanding of automotive quality requirements. Their ability to deliver a complex part ahead of schedule, without compromising on quality, provided us with a critical buffer and de-risked our entire assembly line timeline. They are a highly recommended partner.”

Stable Delivery Through Proactive Project Management

In automotive manufacturing, a delayed component can halt an entire assembly line, incurring massive costs. We mitigate this risk through a transparent and proactive project management framework. Each client is assigned a dedicated Project Manager who serves as your single point of contact, providing regular updates in fluent English. We maintain a “no-surprises” communication policy, meaning you are immediately informed of any potential issues, along with a proposed solution. Our modern facility, equipped with a range of presses, allows for flexible scheduling to ensure your projects for plastic injection molding automotive parts remain on track from design to delivery.

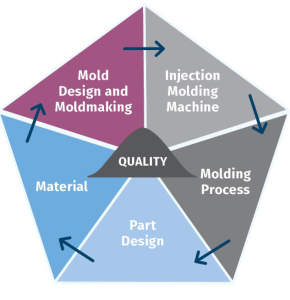

Leveraging Advanced Materials and Processes for Automotive Applications

The performance of plastic injection molding automotive parts is deeply tied to material science and manufacturing techniques. Our expertise covers the full spectrum of automotive requirements:

- Interior Parts: For components like dashboards and door panels, we work with materials like TPU and PP that offer superior haptics, low VOC emissions, and high abrasion resistance. Processes like low-pressure injection molding allow for perfect fabric integration without adhesives.

- Exterior Parts: For bumpers and grilles, we utilize modified PP and PC/PBT blends that provide excellent impact resistance, weatherability, and are ready for painting. Technologies like gas-assisted injection molding create strong, rigid parts with minimal weight and reduced sink marks.

- Under-the-Hood Functional Parts: We produce components like engine covers and fluid reservoirs using high-temperature, chemical-resistant plastics. This translates to parts that are lighter, more corrosion-resistant, and easier to assemble than their metal counterparts.

Frequently Asked Questions (FAQ)

Q1: What is the price range for a small plastic injection molding machine for prototyping?

A: While we are a service provider and not a machinery seller, the small plastic injection molding machine price for a desktop unit can start from $5,000, with industrial-grade machines costing $50,000+. For most businesses, outsourcing to a specialist like DTG is far more capital-efficient, giving you access to a full range of machines and expert operation without the upfront investment and maintenance.

Q2: Can you produce parts that meet both EU and US automotive standards?

A: Absolutely. Our quality systems and material selection processes are designed to meet and exceed the stringent requirements of both European (e.g., REACH, RoHS) and North American automotive markets. We ensure every part is compliant for its intended region.

Q3: What is the minimum order quantity for automotive plastic parts?

A: We are highly flexible. We support everything from low-volume prototyping and bridge production runs of a few hundred parts to full mass production. We tailor our tooling strategy (e.g., using aluminum molds for lower volumes) to make your project economically viable at any scale.

Conclusion: Partner for Your Next Automotive Project

Selecting a Plastic Injection Molding partner is a strategic decision that directly affects your product quality, supply chain resilience, and bottom line. It requires a balance of technical expertise, rigorous quality control, and commercial reliability.

At DTG, we bridge the gap between prototype shops and impersonal mass producers. We offer the technical depth and quality focus demanded by the global automotive industry, backed by a commitment to transparent communication and project management excellence. We don’t just supply parts; we deliver certainty and become a trusted extension of your supply chain.

Ready to streamline your sourcing for automotive plastic parts? Contact our team today for a detailed project review and quotation. Let us demonstrate how our focus on your core procurement needs—quality, delivery, total cost, and communication—makes us the ideal partner for your success.