Resin is a versatile material with applications that span from jewelry making and art to construction and industrial manufacturing. Resins come in various forms, each with distinct properties and ideal uses. This article will explore the different types of resin, highlight the distinctions between resin and plastic, and provide a comprehensive guide on working with materials like plastic resin, epoxy plastic, and polymer resin.

What is Resin?

Resin is a natural or synthetic substance that starts as a liquid and hardens over time. Traditionally, resins were harvested from plants and trees, but today, they are primarily synthetic, designed for durability, flexibility, and a broad range of applications.

Resin vs. Plastic: What’s the Difference?

Resin and plastic are often used interchangeably, but they have distinct differences:

| Aspect | Resin | Plastic |

|---|---|---|

| Definition: | Natural or synthetic substance, sticky when first formed, hardens over time. Often from plant or synthetic sources. | Synthetic material, mostly derived from petroleum or natural gas, used widely in manufacturing. |

| Types: | Natural (like amber, tree sap), synthetic (epoxy, polyester) | Thermoplastics, thermosetting plastics |

| Hardness: | Can range from soft to very hard; often more brittle | Typically more durable, flexible |

| Production: | Extracted from plants or synthesized, involves chemical curing | Produced mainly by polymerization of hydrocarbons |

| Applications: | Used in coatings, adhesives, jewelry, art, construction materials | Used in packaging, automotive parts, electronics, household items |

| Environmental Impact: | Biodegradable (natural resins); synthetic resins may not be eco-friendly | Often non-biodegradable; recyclable but with limitations |

Understanding Plastic Resin

Plastic resin is the base material for most plastics and comes in many forms, such as:

Polyethylene: Commonly used in packaging and consumer goods.

Polypropylene: Known for its durability, used in automotive and medical devices.

Polyvinyl Chloride (PVC): Often used in construction materials.

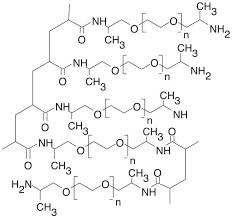

Polymer Resin: The Foundation of Modern Materials

Polymer resins are large molecules made up of repeated units, making them highly customizable. Types of polymer resin include:

- Thermoplastics: These soften when heated and can be reshaped, making them versatile for molding.

- Thermosets: Once hardened, they cannot be reshaped, which is ideal for high-strength applications.

Epoxy Plastic: Characteristics and Applications

Epoxy plastic is a type of polymer resin that becomes hard and durable when cured. Its strength, waterproof qualities, and resistance to chemicals make it ideal for:

- Adhesives: Used for strong bonds in construction and manufacturing.

- Coatings: Applied to protect floors, tables, and other surfaces.

- Electronics: Provides insulation and protection for electronic components.

[elementor-template id=”4330″]

Types of Resins: A Comprehensive Overview

Each resin type has unique properties suitable for specific uses:

- Epoxy Resin: Known for strength and adhesion, used in construction and art.

- Polyester Resin: Less expensive, often used in fiberglass applications.

- Polyurethane Resin: Flexible and impact-resistant, used in foam and rubber applications.

- Silicone Resin: Resistant to heat, often used in molds and sealants.

Applications of Resin Across Industries

Resin’s unique properties make it invaluable in various industries:

- Art and Crafts: Popular for creating jewelry, sculptures, and coatings.

- Construction: Used for adhesives, coatings, and sealing materials.

- Automotive: Provides durability in parts, seals, and coatings.

- Electronics: Acts as insulation and protection for components.

Benefits of Using Resin

- Durability: Offers long-lasting results, especially in high-wear applications.

- Waterproofing: Resins are often resistant to water, ideal for sealing.

- Versatility: Resins can be molded, cast, or layered for various effects.

How Resin is Manufactured

Resin production varies depending on the type, but typically involves polymerization—a process where small molecules join to form long chains. This process allows resins to be tailored for specific needs, like flexibility or durability.

Step-by-Step Guide to Using Epoxy Plastic

- Prepare the Surface: Ensure the area is clean and dry.

- Mix Resin and Hardener: Follow instructions for the correct ratio.

- Apply the Mixture: Pour or spread onto the surface.

- Allow to Cure: Leave undisturbed until fully hardened.

Customizing Resin Projects

Resin is highly customizable, allowing for:

- Coloring: Mix in dyes or pigments.

- Adding Texture: Embed materials like glitter or fabric.

- Finishing Touches: Sand or polish after curing for a glossy look.

Resin in Art and DIY Projects

Popular in creative fields, resin can be used for:

- Casting: Making molds for jewelry or figurines.

- Coating: Sealing artwork or countertops for durability.

- Layering: Creating depth in pieces like river tables or wall art.

Environmental Impact of Resin

While synthetic resins are durable, they aren’t biodegradable, which raises environmental concerns. Using eco-friendly, plant-based resins is one way to mitigate the impact.

[elementor-template id=”4331″]

Frequently Asked Questions About Resin

Q1: Can resin be recycled?

A: Some resins can be recycled, but many, especially thermosetting resins, cannot. Thermoplastics, on the other hand, are recyclable.

Q2: How long does it take for epoxy resin to cure?

A: Epoxy resins typically cure within 24-48 hours, depending on temperature and humidity.

Q3: Can I mix different types of resins?

A: Mixing different resins is not recommended as it can lead to chemical incompatibility.

Q4: Is resin safe for food contact?

A: Certain food-safe resins are available, but always check the product label to confirm.

Q5: What is the difference between casting resin and coating resin?

A: Casting resin is meant for molds and larger pours, while coating resin is designed for surface applications.

Q6: Does resin yellow over time?

A: Many resins can yellow over time due to UV exposure; UV-resistant resins are available to minimize this effect.

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|