Milk jugs are not made using injection molding. Instead, they are typically produced using a process called blow molding. Here’s an overview of why blow molding is the preferred method for manufacturing milk jugs:

Why Milk Jugs Are Blow Molded

1. Blow Molding Process

- Efficiency: Blow molding is an efficient process for creating hollow plastic containers, such as milk jugs, in large quantities.

- Process Steps:

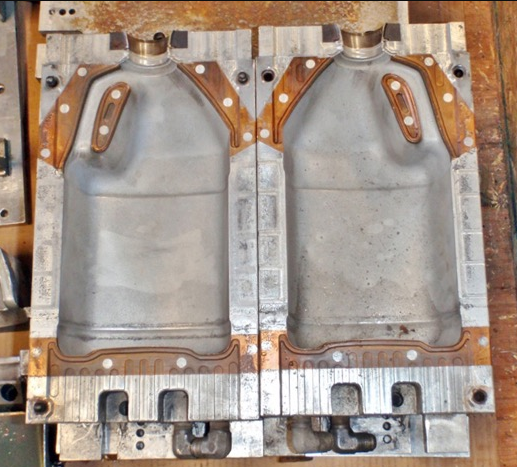

- Extrusion Blow Molding: This involves extruding a parison (a tube-like piece of plastic) which is then clamped into a mold. Air is blown into the parison, expanding it to fit the mold cavity and form the desired shape.

- Injection Blow Molding: This process involves creating a preform using injection molding, which is then heated and placed into a blow mold where air is blown into it to form the final shape.

- Stretch Blow Molding: Commonly used for PET bottles, where a preform is stretched and blown into the final shape.

[elementor-template id=”4330″]

2. Advantages of Blow Molding for Milk Jugs

- Hollow Shapes: Blow molding is ideal for creating hollow shapes, making it perfect for bottles and jugs.

- Uniform Wall Thickness: It ensures uniform wall thickness and structural integrity, important for maintaining the shape and strength of milk jugs.

- Material Efficiency: The process is material-efficient, minimizing waste, which is beneficial for high-volume production of milk containers.

3. Material Used

- High-Density Polyethylene (HDPE): Milk jugs are commonly made from HDPE, a durable and food-safe plastic that can withstand the rigors of transportation and storage.

Comparison with Injection Molding

1. Injection Molding Characteristics

- Solid Parts: Injection molding is typically used for producing solid parts or components with more complex geometries.

- Limited to Smaller Containers: While it can create detailed parts, it is not efficient for producing large hollow objects like milk jugs.

2. Why Injection Molding is Not Used for Milk Jugs

- Hollow Parts Production: Injection molding is not suitable for creating the large, hollow shapes required for milk jugs. The blow molding process is specifically designed to handle this type of product.

- Cost and Efficiency: Blow molding is more cost-effective and efficient for producing high volumes of containers like milk jugs.

[elementor-template id=”4331″]

Conclusion

Milk jugs are produced using blow molding due to its suitability for creating large, hollow containers efficiently and cost-effectively. This process ensures the durability and uniformity needed for milk jugs, which is not achievable with injection molding. For these reasons, blow molding remains the preferred method for manufacturing milk jugs.

Related Conten: Plastic Blow Molding

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|