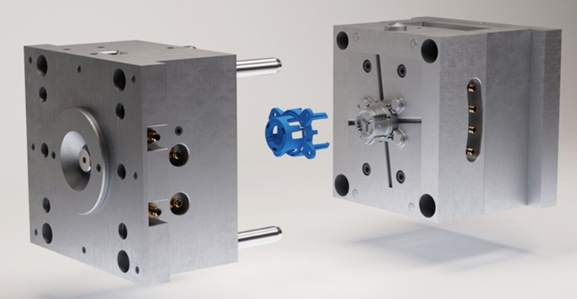

Plastic injection molds are made from a variety of materials, each chosen for its specific properties to ensure the mold’s durability, performance, and suitability for the intended application. The primary materials used for making injection molds are metals, particularly steel and aluminum, due to their strength, wear resistance, and thermal conductivity. Below is an overview of the common materials used in the construction of plastic injection molds:

1. Steel

Steel is the most commonly used material for injection molds due to its excellent mechanical properties and durability. Various types of steel are used, depending on the requirements of the molding process and the properties needed in the final product.

- P20 Steel

- Characteristics: Pre-hardened, medium carbon, low-alloy steel.

- Applications: Suitable for moderate production runs, offering good machinability and polishability.

- Advantages: Cost-effective, durable, and relatively easy to work with.

- H13 Steel

- Characteristics: Chromium hot-work steel.

- Applications: Used for high-volume production and high-temperature applications.

- Advantages: Excellent toughness, thermal stability, and resistance to wear and cracking.

- Stainless Steel

- Characteristics: Corrosion-resistant steel.

- Applications: Ideal for medical, food, and high-humidity environments.

- Advantages: Corrosion resistance, good mechanical properties, and ease of cleaning.

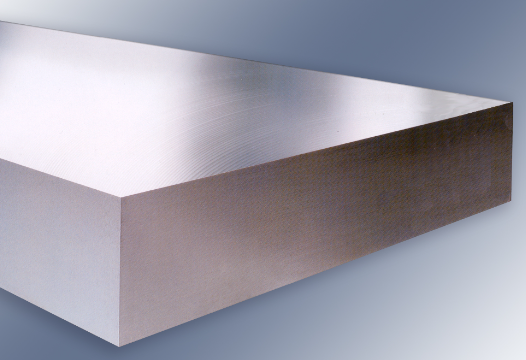

2. Aluminum

Aluminum molds are typically used for prototyping and low to medium-volume production runs. They are chosen for their ease of machining and cost-effectiveness.

- 7075 Aluminum

- Characteristics: High-strength aluminum alloy.

- Applications: Prototyping and low to medium-volume production runs.

- Advantages: Lightweight, excellent machinability, and good thermal conductivity.

- QC-10 Aluminum

- Characteristics: High-strength, high-hardness aluminum.

- Applications: Higher volume production than standard aluminum molds.

- Advantages: Comparable strength to steel molds with reduced weight and cost.

[elementor-template id=”4330″]

3. Beryllium-Copper Alloy

This alloy is used in specific applications where excellent thermal conductivity is required.

- Characteristics: Combines copper’s thermal conductivity with beryllium’s strength.

- Applications: Used in areas of the mold requiring rapid heat removal, such as cores and inserts.

- Advantages: Excellent thermal conductivity, reducing cycle times and improving part quality.

4. Tooling Inserts and Coatings

Molds can also include inserts made from different materials to enhance specific properties or prolong mold life. Additionally, various coatings can be applied to improve performance.

- Ceramic Inserts

- Characteristics: High wear resistance and thermal stability.

- Applications: High-wear areas to extend mold life.

- Advantages: Enhanced durability and performance in high-temperature environments.

- Coatings

- Types: PVD (Physical Vapor Deposition) coatings, TiN (Titanium Nitride), and DLC (Diamond-Like Carbon).

- Applications: Applied to steel molds to improve wear resistance, reduce friction, and prevent corrosion.

- Advantages: Increased mold longevity and improved part ejection.

[elementor-template id=”4331″]

Conclusion

The choice of material for injection molds is critical to the success of the injection molding process. Steel, particularly P20 and H13, is favored for its durability and versatility in high-volume production. Aluminum offers a cost-effective solution for prototyping and lower volume runs, while beryllium-copper alloys and specialized inserts provide enhanced performance in specific applications. Coatings further extend the life and efficiency of the molds, ensuring high-quality and cost-effective production of plastic parts. Understanding these materials helps manufacturers select the right mold construction to meet their production needs and achieve optimal results.

Related Conten: Quick Turn Injection Molding

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|