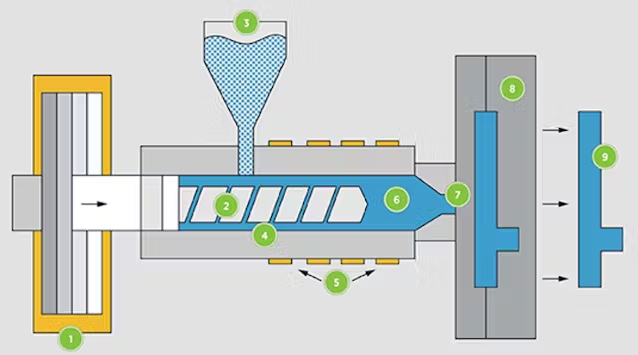

Plastic injection molding is a widely used manufacturing process for producing plastic parts. It involves injecting molten plastic material into a mold, where it cools and solidifies into the final product shape. Here’s a detailed look at how plastic injection molding works:

Key Components of an Injection Molding Machine

- Injection Unit:

- Hopper: Holds the plastic pellets or granules before they enter the machine.

- Barrel: Heats and melts the plastic material.

- Screw: Moves the molten plastic forward and builds up pressure to inject it into the mold.

- Nozzle: Directs the molten plastic into the mold cavity.

- Clamping Unit:

- Mold: Consists of two halves, the core and the cavity, which shape the final part.

- Clamping Mechanism: Holds the mold halves together with sufficient force to withstand the injection pressure.

- Control System:

- Manages the various machine parameters such as temperature, injection pressure, and cycle time.

The Injection Molding Process

- Material Preparation:

- Plastic Pellets: The raw material, usually in pellet form, is fed into the hopper. Common materials include polyethylene (PE), polypropylene (PP), polystyrene (PS), and ABS.

- Melting and Mixing:

- Heating: The barrel contains heaters that melt the plastic pellets as they are moved forward by the rotating screw.

- Mixing: The screw also helps mix the molten plastic to ensure uniform temperature and consistency.

- Injection:

- Filling: Once the plastic is melted and homogenized, the screw pushes the molten plastic through the nozzle into the mold cavity.

- Pressure: High pressure ensures the mold cavity is completely filled, and any intricate details are captured.

- Cooling:

- Solidification: The plastic cools and solidifies in the mold, taking the shape of the cavity.

- Cooling Time: This is a crucial phase, as proper cooling affects the final part’s quality and dimensional stability.

- Mold Opening:

- Ejection: After the part has cooled sufficiently, the clamping unit opens the mold, and ejector pins push the part out of the cavity.

- Cycle Repetition:

- The mold closes again, and the process repeats for the next cycle. This cycle time can range from a few seconds to several minutes, depending on the part size and complexity.

[elementor-template id=”4330″]

Advantages of Plastic Injection Molding

- High Efficiency: Capable of producing large volumes of parts quickly and consistently.

- Complex Designs: Can create intricate shapes and detailed features that would be difficult or impossible with other manufacturing methods.

- Material Variety: Compatible with a wide range of thermoplastics, allowing for versatility in product properties.

- Low Waste: Excess plastic can often be recycled, reducing material waste.

Applications

Plastic injection molding is used across various industries due to its versatility and efficiency. Common applications include:

- Automotive: Dashboard components, bumpers, and interior trims.

- Consumer Goods: Toys, household items, and electronics housings.

- Medical Devices: Syringes, medical equipment housings, and disposable instruments.

- Packaging: Caps, containers, and lids.

Conclusion

Plastic injection molding is a powerful manufacturing process that combines efficiency, versatility, and precision to produce a wide range of plastic parts. By understanding the key components and steps involved in the process, manufacturers can optimize their production and achieve high-quality results suitable for various applications.

Related Conten: https://www.m-dtg.com/service/plastic-assembly-decoration/

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|