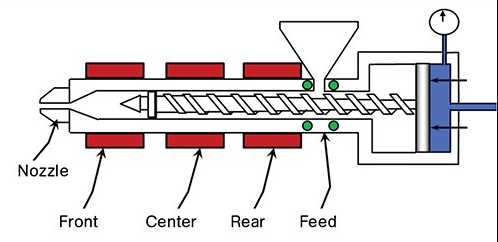

Mold temperature in injection molding refers to the temperature of the mold cavities during the injection molding process. It is a crucial parameter that affects the flow of the molten plastic, the cooling rate, and ultimately the quality of the molded part. Maintaining the correct mold temperature is essential for achieving consistent part dimensions, surface finish, and mechanical properties.

Importance of Mold Temperature

- Flow Properties: Mold temperature affects the viscosity of the molten plastic. A higher mold temperature reduces viscosity, allowing the plastic to flow more easily and fill intricate geometries and thin walls.

- Cooling Rate: The mold temperature influences how quickly the molten plastic cools and solidifies. Proper cooling is essential for minimizing internal stresses and ensuring dimensional stability.

- Surface Finish: Mold temperature impacts the surface quality of the part. Higher mold temperatures can produce smoother surfaces, while lower temperatures may result in surface defects like flow lines and sink marks.

- Cycle Time: The cooling phase is a significant portion of the injection molding cycle. Optimal mold temperature can help balance fast cooling with sufficient material flow, reducing cycle time without compromising part quality.

- Crystallinity: For semi-crystalline polymers, mold temperature affects the degree of crystallinity in the final part, which in turn influences mechanical properties such as strength and stiffness.

Determining Optimal Mold Temperature

- Material Specifications: Each plastic resin has a recommended mold temperature range provided by the manufacturer. This information is typically found in technical data sheets.

- Part Design: The complexity and geometry of the part can influence the required mold temperature. Intricate designs or parts with thin walls may require higher mold temperatures for proper filling.

- Process Requirements: Desired part properties, such as surface finish and mechanical strength, can dictate the optimal mold temperature. For example, a higher mold temperature may be needed for a glossy surface finish.

- Experimental Adjustments: Sometimes, the optimal mold temperature is determined through experimentation and fine-tuning during the initial stages of production.

[elementor-template id=”4330″]

Common Mold Temperatures for Various Plastics

- Polyethylene (PE): 20-60°C (68-140°F)

- Polypropylene (PP): 30-80°C (86-176°F)

- Polystyrene (PS): 50-80°C (122-176°F)

- Polycarbonate (PC): 80-120°C (176-248°F)

- Nylon (PA): 60-120°C (140-248°F)

Managing Mold Temperature

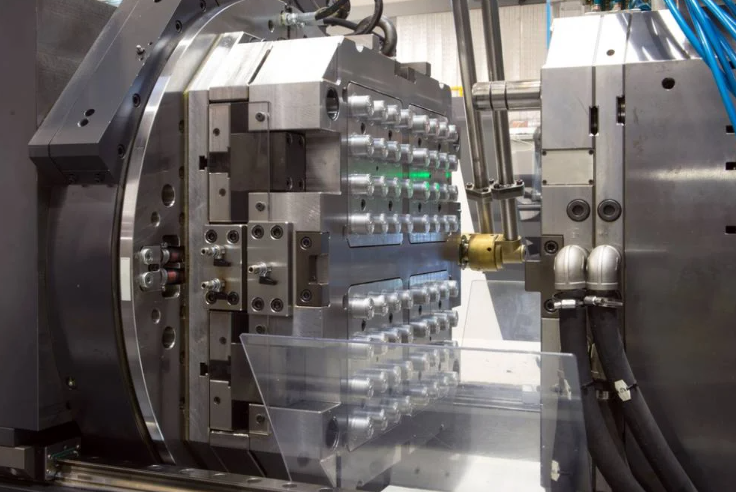

- Temperature Control Units (TCUs): These units circulate a heat transfer fluid (water or oil) through channels in the mold to maintain the desired temperature. They can heat or cool the mold as needed.

- Heaters and Coolers: Embedded heaters can raise the mold temperature, while cooling channels or air vents can lower it. Proper placement and design of these elements are crucial for uniform temperature distribution.

- Monitoring Systems: Sensors and thermocouples are used to continuously monitor the mold temperature. These readings are fed back to the control system to make real-time adjustments.

Effects of Incorrect Mold Temperature

- Too High Mold Temperature:

- Extended Cooling Time: Can increase the overall cycle time, reducing production efficiency.

- Flash: Excessive temperature can cause the molten plastic to flow into parting lines, creating unwanted flash.

- Warpage: Parts may warp or deform if they cool too slowly or unevenly.

- Too Low Mold Temperature:

- Poor Surface Finish: Can lead to surface defects such as flow lines and dull finishes.

- Short Shots: The molten plastic may solidify too quickly, leading to incomplete filling of the mold cavity.

- Internal Stresses: Faster cooling can create internal stresses, compromising the part’s mechanical properties.

[elementor-template id=”4331″]

Practical Example

Consider the production of a plastic housing for electronic devices using polycarbonate (PC):

- Material Selection: The technical data sheet for PC recommends a mold temperature range of 80-120°C.

- Setting Mold Temperature: The injection molding machine’s temperature control unit is set to maintain the mold at 100°C, within the recommended range.

- Injection Process: Molten PC is injected into the mold cavity, flowing easily due to the optimal mold temperature.

- Cooling and Ejection: The part cools uniformly at the set mold temperature, ensuring minimal internal stresses and high dimensional stability.

- Quality Control: The resulting plastic housing has a smooth surface finish and meets all dimensional and mechanical specifications.

Conclusion

Mold temperature is a critical parameter in the injection molding process that significantly affects part quality, cycle time, and material properties. Proper control and optimization of mold temperature are essential for producing high-quality injection-molded parts. By understanding and managing the mold temperature, manufacturers can achieve consistent results, minimize defects, and optimize the efficiency of their production processes.

Related Conten: Plastic Parts Manufacturer

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|