CNC programming refers to the process of creating instructions (often in the form of G-code) that a CNC machine follows to perform operations such as cutting, drilling, milling, and shaping materials. Here’s an overview of CNC programming, its components, and how it works:

Components of CNC Programming

- CAD (Computer-Aided Design):

- Design Creation: The initial step involves creating a detailed digital model or drawing of the part or component using CAD software.

- Dimensions and Geometry: Define the dimensions, shapes, and geometry of the part to be manufactured.

- CAM (Computer-Aided Manufacturing):

- Toolpath Generation: CAM software translates the CAD model into machine-readable instructions.

- G-code Generation: Converts the design into a series of commands (G-code) that the CNC machine can interpret.

- G-code:

- Programming Language: G-code is a standardized programming language used to control CNC machines.

- Commands: Includes commands for movement along different axes (X, Y, Z), tool selection, spindle speed, feed rate, coolant activation, and other parameters.

- Manual and Automated Programming: G-code can be generated manually or automatically through CAM software.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

How CNC Programming Works

- Design Preparation:

- Create a detailed design of the part or component using CAD software.

- Define the dimensions, tolerances, and specifications required for the part.

- Toolpath Generation:

- CAM software analyzes the CAD model and generates toolpaths based on the desired operations (cutting, drilling, milling, etc.).

- Optimizes toolpaths for efficiency, minimizing unnecessary movements and reducing machining time.

- G-code Generation:

- CAM software generates G-code based on the toolpaths and machine specifications.

- G-code includes specific commands for each operation, detailing tool movements, spindle speeds, feed rates, and other parameters.

- Machine Setup:

- Load the G-code file into the CNC machine’s controller.

- Securely mount the workpiece and select the appropriate cutting tools.

- Execution:

- The CNC machine’s controller reads and executes the G-code instructions.

- Automated movements of the machine’s axes and tools perform the programmed operations on the workpiece.

- Continuous monitoring ensures accuracy and adjusts parameters as necessary.

Importance of CNC Programming

- Precision and Accuracy: CNC programming ensures precise control over tool movements and operations, producing parts with consistent quality.

- Efficiency: Optimized toolpaths and parameters reduce material waste and machining time.

- Flexibility: Easily modify programs for different parts and prototypes without the need for physical tool changes.

- Automation: Minimizes human error and increases productivity by automating repetitive tasks.

Applications of CNC Programming

- Manufacturing: Used in industries such as automotive, aerospace, medical, electronics, and consumer goods for mass production and prototyping.

- Prototyping: Rapidly iterate designs and produce prototypes for testing and validation.

- Customization: Enables the production of complex and customized parts that are difficult to manufacture manually.

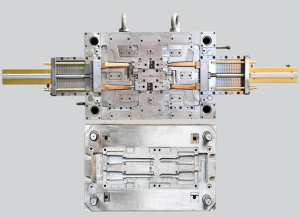

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Conclusion

CNC programming is integral to modern manufacturing, enabling the precise control and automation of CNC machines. By translating design specifications into machine-readable instructions (G-code), CNC programming ensures efficient and accurate production of parts and components across various industries. Mastering CNC programming requires proficiency in CAD/CAM software and understanding of machining principles to optimize operations and achieve desired outcomes.

Related Conten: Custom Plastic Fabrication