Glass cannot be injection molded in the same way as plastics due to its distinct physical properties. Traditional injection molding involves melting the material and injecting it into a mold under high pressure. While plastics can be easily melted and molded, glass behaves differently, necessitating other methods. Here’s why and how glass is typically processed:

Why Glass Cannot Be Injection Molded

1. High Melting Point

- Temperature Requirements: Glass has a much higher melting point than most plastics, often exceeding 1000°C (1832°F). Typical injection molding machines are not designed to operate at these extreme temperatures.

2. Viscosity and Flow

- Viscosity Differences: When molten, glass is highly viscous compared to plastics. This high viscosity makes it difficult to inject molten glass into a mold through a narrow nozzle, which is standard in injection molding processes.

3. Cooling and Solidification

- Controlled Cooling: Glass requires controlled cooling (annealing) to prevent internal stresses and cracking. Rapid cooling, as seen in injection molding, would cause significant internal stresses, leading to defects and breakage.

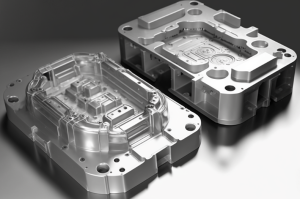

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

How Glass is Typically Processed

1. Glass Blowing

- Traditional Method: Involves shaping molten glass by blowing air into it through a tube. This method is used for creating hollow objects like bottles, vases, and light bulbs.

2. Pressing

- Pressing: Molten glass is pressed into a mold using a plunger. This method is often used for making flat glass products like lenses and dinnerware.

3. Casting

- Glass Casting: Molten glass is poured into molds and allowed to cool slowly. This method is used for creating thick or intricate glass items, including sculptures and decorative pieces.

4. Float Glass Process

- Float Glass: Involves floating molten glass on a bed of molten tin to create flat, uniform glass sheets. This method is primarily used in the production of window glass and mirrors.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Alternative Approaches in Glass Processing

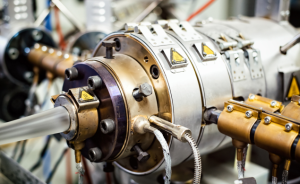

1. Injection Molding of Glass-Reinforced Plastics

- Composite Materials: While pure glass cannot be injection molded, glass-reinforced plastics (composites) can be. These materials combine plastic polymers with glass fibers to improve strength and durability, making them suitable for injection molding.

2. Sol-Gel Process

- Advanced Techniques: The sol-gel process involves creating glass at a much lower temperature by transitioning from a liquid “sol” to a solid “gel” phase, which can then be molded. This process is used for specialized applications like coatings and optical components.

Conclusion

While glass itself cannot be injection molded due to its high melting point, viscosity, and cooling requirements, various alternative processes are used to shape and form glass. Traditional glass processing methods like blowing, pressing, casting, and the float process are well-established techniques tailored to the unique properties of glass. For applications requiring the advantages of injection molding, glass-reinforced plastics provide a viable alternative.

Related Conten: Quick Turn Injection Molding