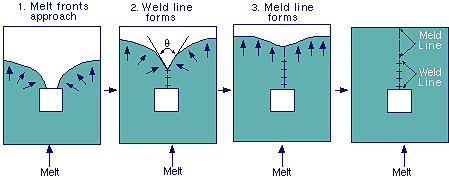

Weld lines, also known as knit lines or meld lines, are visible lines on a molded part where two or more flow fronts of molten plastic meet during the injection molding process. These lines can be points of structural weakness and aesthetic defects. Avoiding or minimizing weld lines is crucial for maintaining the integrity and appearance of the final product. Here are several strategies to avoid weld lines in injection molding:

1. Optimize Mold Design

Gate Location:

- Place gates in a way that allows for uniform flow of material and minimizes the number of flow fronts that meet.

- Avoid gating into areas that will force the flow fronts to meet at critical points of the part.

Runner and Gate Design:

- Use balanced runner systems to ensure equal flow paths and reduce the chance of weld lines.

- Consider using multiple gates or hot runners to control flow and reduce weld lines.

Part Geometry:

- Design parts with uniform wall thickness to ensure consistent flow and minimize the formation of multiple flow fronts.

- Incorporate features like flow leaders and deflectors to control and direct the flow of molten plastic.

[elementor-template id=”4330″]

2. Adjust Processing Parameters

Injection Speed:

- Increase injection speed to ensure that the material fills the mold cavity quickly, reducing the time for flow fronts to cool and create weld lines.

Melt Temperature:

- Increase the melt temperature to improve flowability and ensure that flow fronts merge more seamlessly.

Mold Temperature:

- Increase the mold temperature to maintain the flow fronts in a molten state longer, promoting better fusion.

Packing Pressure:

- Increase packing pressure to help material flow into weld line areas and improve their integrity.

3. Material Selection and Additives

Material Choice:

- Select materials with better flow characteristics that can help reduce the formation of weld lines.

- Some materials are more prone to weld lines than others due to their viscosity and cooling properties.

Additives:

- Use appropriate additives, such as flow enhancers or lubricants, to improve the material’s flow properties.

[elementor-template id=”4331″]

4. Venting and Degassing

Mold Venting:

- Ensure proper venting to allow trapped air to escape, preventing air pockets and weak weld lines.

- Place vents near areas where weld lines are likely to form to allow for smoother merging of flow fronts.

Degassing:

- Properly dry the material to remove any moisture that could cause gas formation and result in weld lines.

5. Advanced Techniques

Flow Simulation Software:

- Use flow simulation software during the design phase to predict and identify potential weld line locations.

- Make design and process adjustments based on simulation results to minimize weld lines.

Vacuum Assist:

- Implement vacuum-assisted molding to reduce air entrapment and improve the merging of flow fronts.

Summary of Strategies

| Strategy | Action |

|---|---|

| Optimize Mold Design | Gate location, runner design, part geometry |

| Adjust Processing Parameters | Injection speed, melt temperature, mold temperature, packing pressure |

| Material Selection and Additives | Use materials with good flow properties, apply flow enhancers |

| Venting and Degassing | Proper mold venting, degassing material |

| Advanced Techniques | Flow simulation, vacuum assist |

Conclusion

Avoiding weld lines in injection molding requires a combination of optimizing mold design, adjusting processing parameters, selecting appropriate materials, and sometimes using advanced techniques. By carefully considering these factors and implementing the appropriate strategies, you can significantly reduce or eliminate weld lines, resulting in stronger and more aesthetically pleasing molded parts.

Related Conten: https://www.m-dtg.com/landing-page/plastic-parts-manufacturer/

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|