The tonnage of an injection molding machine refers to the clamping force that the machine can exert to keep the mold closed during the injection process. This force is measured in tons and is a critical parameter in the selection and operation of injection molding machines. Here’s a detailed explanation of what tonnage is, why it matters, and how it is calculated and applied in the injection molding process.

Definition of Tonnage

Tonnage: The clamping force, measured in tons, applied by an injection molding machine to keep the mold halves closed during the injection of molten plastic.

Importance of Tonnage

- Mold Integrity:

- The clamping force ensures that the mold remains tightly closed and aligned during the injection process, preventing material from leaking out (flash) and ensuring the accurate formation of parts.

- Part Quality:

- Proper tonnage helps maintain consistent cavity pressure, resulting in uniform part dimensions, surface finish, and mechanical properties.

- Defect Prevention:

- Adequate clamping force prevents defects such as flash, short shots, and incomplete filling by ensuring the mold stays closed and the cavity is properly filled.

- Machine and Mold Protection:

- Using the correct tonnage prevents excessive stress on the mold and the machine, reducing wear and tear and extending the lifespan of both.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Factors Influencing Tonnage Requirements

- Part Size and Design:

- Larger and more complex parts typically require higher clamping forces due to greater projected surface area and higher injection pressures needed to fill the mold.

- Material Type:

- Different plastics have varying viscosities and flow characteristics, affecting the pressure required to fill the mold and, consequently, the tonnage needed.

- Number of Cavities:

- Molds with multiple cavities require higher clamping forces to ensure that all cavities are filled uniformly and the mold stays closed under the increased pressure.

- Projected Area:

- The projected area of the part (the area seen when looking directly at the part’s surface from above) directly impacts the clamping force needed. This area is subjected to the injection pressure during molding.

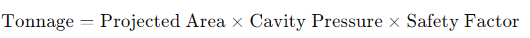

Calculating Tonnage

The basic formula to estimate the required tonnage is:

- Projected Area (A): The area of the part that is subjected to the clamping force. This includes the area of the part and any runners or sprues.

- Cavity Pressure (P): The pressure exerted by the molten plastic in the cavity, typically measured in psi or bar. This varies based on the material and part design.

- Safety Factor (S): A factor typically ranging from 1.5 to 2 to account for variations in the process and ensure reliable mold operation.

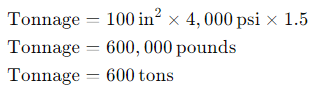

Example Calculation

For a part with a projected area of 100 square inches, using a material with an average cavity pressure of 4,000 psi and a safety factor of 1.5:

So, a machine with a clamping force of at least 600 tons would be required.

Selecting the Right Tonnage

- Avoid Undersizing:

- Insufficient clamping force can lead to mold separation, flash, and poor part quality.

- Avoid Oversizing:

- Excessive clamping force can cause unnecessary wear on the mold and machine, leading to higher maintenance costs and potential damage.

- Consider Material and Process Variability:

- Account for variations in material properties and processing conditions by incorporating a safety factor in the tonnage calculation.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Conclusion

Tonnage in injection molding machines is a crucial factor that affects the quality, consistency, and efficiency of the molding process. Proper calculation and selection of the clamping force ensure mold integrity, part quality, and operational longevity. By understanding and accurately determining the required tonnage based on part design, material properties, and other factors, manufacturers can optimize their injection molding operations for better results and cost efficiency.

Related Conten: Injection Molding Factory