The strength of injection-molded gun parts compared to milled steel parts varies significantly due to the inherent differences in material properties and manufacturing processes. Here’s a detailed comparison of injection-molded plastic gun parts and milled steel parts, focusing on their strength and suitability for various applications.

Material Properties

- Injection-Molded Plastics:

- Common Materials: High-strength polymers such as glass-filled nylon, polycarbonate (PC), and acrylonitrile butadiene styrene (ABS).

- Tensile Strength: Typically ranges from 60-100 MPa for high-performance polymers and can exceed 150 MPa for glass-filled variants.

- Impact Resistance: Generally good, with some polymers offering excellent toughness.

- Density: Lower than steel, resulting in lighter components.

- Milled Steel:

- Types of Steel: Carbon steel, stainless steel, and alloy steels are commonly used.

- Tensile Strength: Can range from 250 MPa to over 1500 MPa, depending on the type and heat treatment.

- Impact Resistance: Very high, especially for toughened and tempered steels.

- Density: Much higher than plastics, leading to heavier components.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Strength Comparison

- Tensile Strength:

- Injection-Molded Plastics: Tensile strength is significantly lower than steel. Even with high-performance polymers, the tensile strength of plastics is only a fraction of that of steel.

- Milled Steel: Far superior in tensile strength, making it more suitable for load-bearing and high-stress applications.

- Impact Resistance:

- Injection-Molded Plastics: Certain plastics like polycarbonate have excellent impact resistance, which can be advantageous for parts that need to absorb shock or impact.

- Milled Steel: Exceptional impact resistance, particularly important for components subjected to sudden forces or impact.

- Durability and Wear Resistance:

- Injection-Molded Plastics: Generally good for non-load-bearing parts but can wear more quickly under friction and stress compared to steel.

- Milled Steel: Superior wear resistance, especially when treated with surface hardening techniques.

Applications in Firearms

- Injection-Molded Plastic Parts:

- Suitable Components: Non-critical components such as grips, stocks, magazine followers, and housings.

- Advantages: Lighter weight, lower cost, corrosion resistance, and ease of manufacturing complex shapes.

- Limitations: Lower strength and durability compared to steel, not suitable for high-stress components like barrels, bolts, or frames.

- Milled Steel Parts:

- Suitable Components: Critical, high-stress components such as barrels, bolts, frames, and action components.

- Advantages: High strength, durability, and wear resistance, essential for withstanding the pressures and forces in a firearm.

- Limitations: Heavier, more expensive to machine, and susceptible to corrosion without proper treatment.

Practical Considerations

- Weight Reduction:

- Using injection-molded plastic parts can significantly reduce the overall weight of a firearm, enhancing portability and reducing fatigue during use.

- Cost Efficiency:

- Injection molding is more cost-effective for mass production of complex shapes and non-critical components, while milled steel parts are more expensive due to material costs and machining time.

- Design Flexibility:

- Injection molding allows for more intricate designs and integration of features that would be difficult or costly to machine in steel.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Conclusion

Injection-molded plastic gun parts offer significant advantages in terms of weight reduction, cost, and design flexibility, making them suitable for non-critical components. However, when it comes to strength, durability, and performance under high stress, milled steel parts are far superior and essential for critical firearm components. The choice between injection-molded plastics and milled steel ultimately depends on the specific requirements of the firearm and the intended use of the parts.

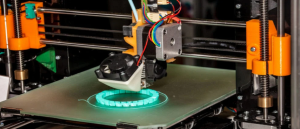

Related Conten: Mold Manufacturing / 3D Printing