Scientific Injection Molding (SIM), also known as Decoupled Molding, is an advanced injection molding technique that emphasizes the use of data and scientific principles to optimize the molding process. The goal of SIM is to produce high-quality, consistent parts by systematically controlling and understanding the various stages of the injection molding process.

Key Principles of Scientific Injection Molding

1. Data-Driven Approach

SIM relies heavily on the collection and analysis of data at every stage of the injection molding process. This data includes parameters such as temperature, pressure, and time, which are used to develop a comprehensive understanding of the process and its effects on the final product.

2. Decoupled Molding

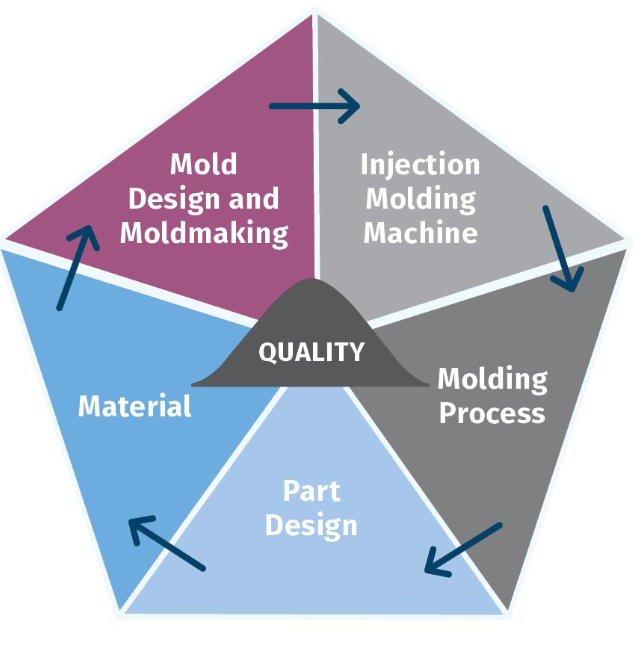

In SIM, the molding process is decoupled into distinct stages, each optimized separately to ensure consistency and quality. The typical stages include filling, packing, and cooling:

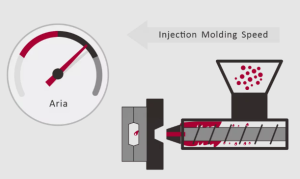

- Filling: The mold cavity is filled with molten plastic at a controlled rate to ensure uniform flow and minimize defects.

- Packing: Additional material is injected under pressure to compensate for shrinkage and ensure the mold is fully packed.

- Cooling: The part is allowed to cool and solidify under controlled conditions to prevent warping and dimensional inaccuracies.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

3. Scientific Methods

SIM employs scientific methods and principles such as Design of Experiments (DOE), Statistical Process Control (SPC), and thorough material characterization to optimize the process and achieve consistent results.

Benefits of Scientific Injection Molding

1. Improved Part Quality

By systematically controlling and optimizing each stage of the injection molding process, SIM produces parts with superior mechanical properties, dimensional accuracy, and surface finish.

2. Process Consistency

SIM reduces variability in the injection molding process, leading to more consistent production runs and fewer defective parts. This consistency is crucial for industries with stringent quality requirements, such as automotive and medical.

3. Reduced Cycle Times

Optimizing the injection molding process can lead to shorter cycle times, increasing production efficiency and reducing costs.

4. Better Understanding of the Process

SIM provides a deeper understanding of the injection molding process, enabling manufacturers to troubleshoot issues more effectively and implement continuous improvements.

Implementation of Scientific Injection Molding

1. Material Characterization

Understanding the properties of the plastic material being used is crucial for SIM. This includes determining the material’s viscosity, thermal properties, and behavior under different processing conditions.

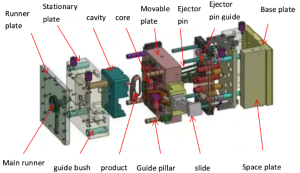

2. Process Mapping

A detailed process map is created to document each stage of the injection molding process, including all relevant parameters such as temperature, pressure, and time. This map serves as a baseline for optimization.

3. Design of Experiments (DOE)

DOE is used to systematically vary process parameters and study their effects on part quality. This helps identify the optimal settings for each stage of the process.

4. Monitoring and Control

Advanced monitoring systems are employed to continuously measure process parameters and ensure they remain within specified ranges. Statistical Process Control (SPC) techniques are used to detect and correct deviations in real-time.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

5. Validation and Testing

The optimized process is validated through rigorous testing to ensure it consistently produces high-quality parts. This includes mechanical testing, dimensional inspection, and visual inspection.

Practical Example

Consider the production of a high-precision gear used in an automotive transmission system:

Material Selection

A high-performance thermoplastic, such as polyamide (nylon), is chosen for its strength, durability, and wear resistance.

Process Mapping

The injection molding process for the gear is mapped out, including detailed parameters for the filling, packing, and cooling stages.

Design of Experiments

DOE is conducted to study the effects of various parameters, such as injection speed, packing pressure, and cooling time, on the gear’s quality. The optimal settings are identified to minimize defects such as warping and dimensional inaccuracies.

Monitoring and Control

Advanced sensors and monitoring systems are installed on the injection molding machine to continuously measure key parameters. SPC techniques are used to detect any deviations from the optimal process settings.

Validation and Testing

The optimized process is validated through extensive testing, including tensile strength tests, dimensional inspections, and visual inspections. The results confirm that the gears meet all quality and performance requirements.

Conclusion

Scientific Injection Molding is a sophisticated approach that leverages data and scientific principles to optimize the injection molding process. By decoupling the process into distinct stages and systematically controlling key parameters, SIM produces high-quality, consistent parts with improved efficiency. Implementing SIM requires a thorough understanding of material properties, process mapping, and advanced monitoring and control techniques, but the benefits in terms of part quality, process consistency, and production efficiency make it a valuable methodology for advanced manufacturing applications.

Related Conten: Prototype Manufacturing