Home » Case Products » Injection Molded Plastic Gears

Injection Molded Plastic Gears

We specialize in producing high-quality, precision-engineered plastic gears using advanced injection molding techniques. With our expertise and state-of-the-art equipment, we offer durable, reliable, and cost-effective gear solutions tailored to meet your specific application needs.

Our Expertise:

- Custom Design: Our team of engineers works closely with you to design custom gear solutions that meet your requirements in terms of size, tooth profile, pitch, material, and performance characteristics.

- Material Selection: We offer a wide range of plastic materials suitable for gear manufacturing, including nylon (PA), acetal (POM), polyethylene (PE), and more, chosen for their excellent mechanical properties, wear resistance, and dimensional stability.

- Injection Molding Precision: We utilize advanced injection molding technology and tooling to achieve precise dimensions, tight tolerances, and consistent quality across all gears, ensuring smooth operation and optimal performance in your applications.

Key Features:

- Durability: Our injection molded plastic gears are built to withstand demanding operating conditions, including high loads, speeds, temperatures, and corrosive environments, providing long-lasting durability and reliability.

- Low Noise and Vibration: Plastic gears offer quieter operation compared to metal gears, thanks to their inherent damping properties and smoother tooth engagement, reducing noise and vibration in your machinery and equipment.

- Cost-Effectiveness: Injection molding offers cost-effective solutions for gear manufacturing, particularly for high-volume production runs, providing excellent value for your investment and helping you minimize production costs.

Applications:

Our injection molded plastic gears find applications across various industries, including:

- Automotive: Transmission systems, power seats, HVAC controls, and power window mechanisms.

- Consumer Electronics: Printers, scanners, copiers, cameras, and audio/video equipment.

- Industrial Machinery: Conveyors, actuators, pumps, compressors, and gearboxes.

- Medical Devices: Diagnostic equipment, surgical instruments, and laboratory devices.

- Robotics and Automation: Robotic arms, linear actuators, and motion control systems.

Benefits:

- High Precision: Injection molding allows for the production of gears with precise dimensions, accurate tooth profiles, and tight tolerances, ensuring smooth and efficient power transmission in your applications.

- Corrosion Resistance: Plastic gears are resistant to corrosion, chemicals, and moisture, making them suitable for use in harsh environments and outdoor applications where metal gears may corrode or rust.

- Lightweight: Plastic gears are significantly lighter than metal gears, reducing inertia, energy consumption, and wear on mating components, while also simplifying assembly and handling.

Why Choose Us?

- Experience: With years of experience in injection molding and gear manufacturing, we have the expertise to deliver high-quality, custom gear solutions that meet your exact specifications and performance requirements.

- Quality Assurance: We adhere to strict quality control standards throughout the manufacturing process to ensure that every gear meets the highest standards of quality, reliability, and performance.

- Customer Satisfaction: We prioritize customer satisfaction and strive to exceed your expectations by providing personalized service, timely communication, and superior products that meet or exceed your requirements.

Partner with us for your injection molded plastic gear manufacturing needs, and let us help you create custom gear solutions that deliver precision, durability, and value for your applications. Contact us today to discuss your project requirements or request a quote. We look forward to working with you!

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Trusted Injection Molding Manufacturers: Quality and Precision for Your Projects

Read more -

Soft Plastic Injection Molds Plastic Shrimp, Plastic Bug, Plastic Lures

Read more -

Polycarbonate Injection Molding: Durable and Impact-Resistant Solutions for High-Performance Applications

Read more -

Custom Plastic Bracelets – Plastic Molding

Read more -

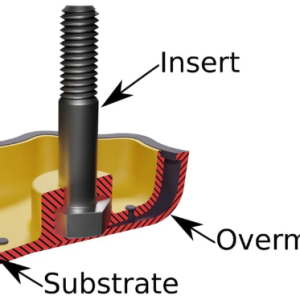

Enhance Your Product’s Functionality with Expert Overmolding Injection Molding

Read more -

TPU Injection Molding Solutions

Read more