Is PPE Injection Molding the Best Manufacturing Solution for Your Safety Product Line?

In the rapidly growing field of safety products, manufacturers must choose production methods that balance efficiency, cost, and quality. PPE injection molding has emerged as a leading solution for producing high-volume personal protective equipment with consistency and precision. But is it the right choice for your specific product line?

What Is PPE Injection Molding?

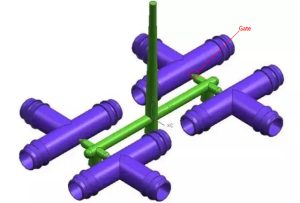

PPE injection molding is a manufacturing process in which melted plastic is injected into a custom mold to create consistent and high-quality PPE components. It is commonly used for producing:

Face shield frames

Protective goggles

Respirator parts

Helmets and headgear components

This method is especially beneficial for companies that require scalable production of plastic-based safety equipment.

Top Advantages of PPE Injection Molding

Cost-Efficiency at Scale

Once the mold is developed, PPE injection molding becomes highly economical for mass production. The per-unit cost drops significantly with higher output, making it ideal for large-scale PPE manufacturing.

High Precision and Consistency

Safety products must meet strict standards. This method delivers highly uniform parts, ensuring each PPE item is built to exact specifications.

Wide Range of Material Options

PPE injection molding supports various thermoplastics like polypropylene, polycarbonate, and ABS—materials known for durability, impact resistance, and chemical protection.

Complex Designs Made Simple

The process allows for ergonomic and functional designs, enhancing the usability and comfort of safety gear like respirator masks and protective eyewear.

Potential Drawbacks to Consider

High Initial Tooling Costs

Creating the mold requires a significant upfront investment, which may not be feasible for startups or small production runs.

Long Lead Time

Designing and producing a custom mold can take several weeks, which might delay time-sensitive PPE launches.

Limited Flexibility for Design Changes

Once the mold is made, modifying the design can be costly and time-consuming, making this method best suited for finalized product designs.

Is PPE Injection Molding Right for Your Safety Product Line?

PPE injection molding is best suited for companies that:

Need to produce PPE at scale

Require high precision and repeatability

Are working with finalized, stable product designs

Want to reduce long-term per-unit costs

Seek to maintain consistent product quality

If your business falls into these categories, injection molding could offer unmatched advantages for your PPE line.

Alternative Manufacturing Methods to Consider

If PPE injection molding isn’t a perfect fit for your current stage, consider these options:

3D Printing: Ideal for prototyping and small-batch PPE items

Thermoforming: Great for face shields and curved surfaces

Compression Molding: Better for rubber-based PPE like gloves and pads