Introduction

Choosing the right PPE injection molding manufacturer is a critical step in ensuring the success of your personal protective equipment (PPE) product. From material selection to compliance with safety regulations, the manufacturer you partner with plays a key role in cost, quality, and efficiency. In this guide, we break down the factors you need to consider when selecting the ideal injection molding partner for your PPE project.

1. Evaluate the Manufacturer’s Experience with PPE Products

Not all injection molding manufacturers specialize in PPE. Look for companies that have a strong portfolio of PPE items such as face shields, goggles, respirator components, or protective housings. Experience ensures that the manufacturer understands the unique challenges involved, including regulatory requirements and safety standards.

2. Verify Certifications and Compliance

A reliable PPE injection molding manufacturer should be ISO 9001 certified and compliant with other relevant standards like FDA, CE, or NIOSH, depending on your market. Certifications indicate a commitment to quality assurance and adherence to global production guidelines.

3. Assess Material Expertise

PPE requires high-performance, medical-grade or industrial-grade plastics like polycarbonate, polypropylene, or ABS. The right manufacturer should guide you on material selection based on your product’s use case, ensuring durability, flexibility, and resistance to chemicals or impact.

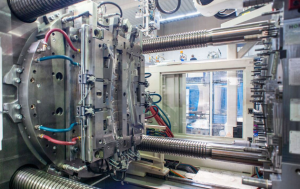

4. Check for In-House Capabilities

Choose a manufacturer that offers end-to-end services, including mold design, tooling, prototyping, and post-processing. This ensures better quality control, faster production cycles, and cost-efficiency. Having in-house capabilities also allows for greater flexibility when making adjustments during the project.

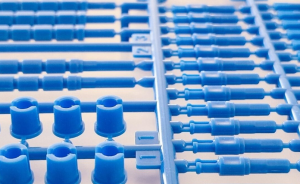

5. Request Samples and Review Quality Control Processes

Ask for product samples or case studies from previous PPE molding projects. Evaluate their surface finish, dimensions, and durability. Also, inquire about their quality control systems—do they perform in-process inspections, testing for material consistency, and batch traceability?

6. Discuss Lead Time and Production Capacity

Timeliness is crucial, especially when producing PPE for emergency response or healthcare supply chains. Make sure the manufacturer can meet your required timeline and volume. Understand their production capacity and whether they can scale up if needed.

7. Review Communication and Project Management

A transparent and responsive manufacturer will provide regular updates, design feedback, and support throughout your project. Choose a partner with strong project management protocols, who understands deadlines, documentation, and communication expectations.

8. Compare Pricing, But Don’t Sacrifice Quality

While cost is important, choosing the cheapest manufacturer may compromise quality or compliance. Balance affordability with reliability and proven experience. A good PPE injection molding partner will offer competitive pricing without cutting corners.

Conclusion

Finding the right PPE injection molding manufacturer involves a balance of technical expertise, certifications, communication, and scalability. By carefully vetting potential partners with the criteria above, you ensure a smoother development process and a high-quality end product that meets safety requirements.