Common Mistakes to Avoid in PPE Injection Molding ProjectsIntroduction

PPE injection molding plays a critical role in producing reliable medical and industrial safety gear, from face shields to respirator components. With demand for high-quality protective equipment growing, manufacturers cannot afford mistakes that compromise safety, efficiency, or compliance. Understanding the most common pitfalls in PPE injection molding projects can help businesses save costs, reduce waste, and ensure top-quality products.

Lack of Proper Material Selection

One of the biggest mistakes is choosing the wrong resin for PPE products. For example, not all plastics offer the same balance of strength, flexibility, and chemical resistance. Materials like polypropylene (PP) and polycarbonate (PC) are widely used for their durability and transparency, but using unsuitable resins can lead to weak or brittle parts. Always consult material experts and test compatibility with the intended application.

Overlooking Design for Manufacturability (DFM)

Poor part design is another common issue. Without considering manufacturability, parts may have thick walls, sharp corners, or improper draft angles that cause defects like warping or sink marks. Collaborating with engineers early on ensures the design is optimized for injection molding and reduces costly revisions later.

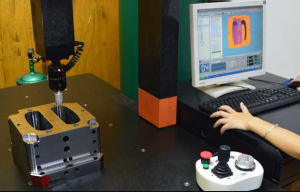

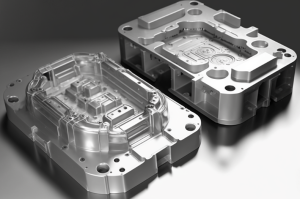

Ignoring Mold Tooling Quality

The mold is the heart of the injection molding process. Low-quality or poorly maintained molds can result in uneven surfaces, flash, or short shots. Investing in precision tooling and regular maintenance is essential for producing consistent, high-quality PPE parts.

Inadequate Process Control

Even with the best materials and molds, improper process settings—such as incorrect injection pressure, temperature, or cooling time—can lead to defective products. Lack of strict process monitoring often results in inconsistent batches. Implementing advanced process controls and automation helps maintain uniformity.

Skipping Regulatory Compliance Checks

PPE must meet strict health and safety standards. Overlooking compliance with certifications like FDA, CE, or ISO can lead to rejected products and legal issues. Manufacturers should integrate regulatory requirements into the design, material selection, and testing phases to ensure products pass inspections smoothly.

Poor Supplier Communication

Another frequent mistake is failing to maintain clear communication with suppliers. Misunderstandings about tolerances, timelines, or quality expectations can delay production. Choosing a reliable injection molding partner and establishing transparent communication channels is vital for project success.

Conclusion

PPE injection molding projects require careful planning, quality control, and regulatory awareness. By avoiding common mistakes such as poor material selection, inadequate mold tooling, and lack of compliance checks, manufacturers can improve efficiency, reduce costs, and deliver safer protective equipment. A proactive approach ensures that PPE products not only meet industry standards but also protect the people who rely on them every day.