Yes, melamine formaldehyde (MF) can be injection molded, but the process differs from typical thermoplastic injection molding due to its thermosetting nature. Melamine formaldehyde is a type of aminoplast resin, which is a thermosetting plastic. Here’s an overview of how it can be injection molded, including the process and its applications:

Melamine Formaldehyde Injection Molding Process

1. Material Characteristics

- Thermosetting Plastic: Unlike thermoplastics, melamine formaldehyde does not melt upon reheating. Instead, it undergoes a chemical reaction during molding that creates a rigid, infusible structure.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

2. Molding Process

- Preprocessing: The raw melamine formaldehyde resin is often mixed with fillers, pigments, and other additives to achieve the desired properties.

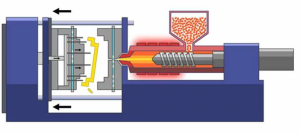

- Injection Molding Machine: A specialized injection molding machine designed for thermosetting plastics is used. These machines typically have features such as temperature control and high-pressure capabilities to handle the material’s properties.

- Heating and Injection: The melamine formaldehyde resin is heated and injected into the mold cavity. The heat and pressure initiate the chemical curing reaction.

- Curing: The material cures (sets) in the mold, forming a hard, durable part. This curing process is irreversible, meaning the part cannot be re-melted and reshaped.

- Cooling and Ejection: After curing, the part is cooled and ejected from the mold.

3. Post-Molding Operations

- Finishing: Depending on the application, additional finishing operations like trimming, polishing, or coating may be required to achieve the desired surface quality.

Advantages of Using Melamine Formaldehyde

1. Durability and Strength

- Hardness: Melamine formaldehyde is known for its hardness, making it suitable for applications where wear resistance is important.

- Chemical Resistance: It has excellent resistance to chemicals, heat, and moisture, making it ideal for applications that require long-term durability.

2. Aesthetic Qualities

- Color and Finish: Melamine formaldehyde can be easily colored and finished to achieve various aesthetic effects, including glossy surfaces.

3. Electrical Properties

- Insulation: It is an excellent electrical insulator, making it suitable for electrical and electronic components.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Applications of Melamine Formaldehyde

1. Household Goods

- Tableware: Plates, bowls, and other dinnerware are commonly made from melamine due to its durability and aesthetic qualities.

- Kitchenware: Kitchen utensils and appliances often use melamine for its heat resistance and hardness.

2. Electrical Components

- Switches and Sockets: Due to its electrical insulating properties, melamine formaldehyde is used in electrical switches, sockets, and other components.

- Electrical Housings: Protective housings for electrical devices often utilize melamine formaldehyde for its durability and insulation.

3. Industrial Applications

- Automotive Parts: Certain automotive components, especially those requiring heat and chemical resistance, can be made from melamine formaldehyde.

- Adhesives and Laminates: Melamine formaldehyde is also used in adhesives, laminates, and coatings due to its strong bonding properties and durability.

References

- Plastics Technology: Overview of thermosetting plastics and their molding processes, including melamine formaldehyde. Plastics Technology

- SpecialChem: Information on melamine formaldehyde properties and applications. SpecialChem

- ScienceDirect: Detailed technical information on the injection molding of melamine formaldehyde. ScienceDirect

By leveraging the properties of melamine formaldehyde and using appropriate injection molding techniques, manufacturers can produce a wide range of durable and aesthetically pleasing products.

Related Conten: Custom Molders Corp