1: Reduction Part Volume

Materials used in 3D printing processes, such as nylon powder (SLS) or rolls of thermoplastic filament (FDM) are a main price element. The good news is, additive manufacturing processes are really effective due to the fact that printers can either reuse some unused material (e.g. non-melted nylon powder that works as an assistance structure in SLS) or create minimal waste material (e.g. FDM cartridges that only extrude enough filament to make the part and assistance structure).

One method to restrict volume, but still protect general measurements, is lightweighting. Producing pockets in layouts will certainly minimize material usage, making it more economical to build. When producing a pocket, make certain to produce a leave opening for un-sintered (SLS and DMLS) or assistance (PolyJet) product removal.

For FDM printing, altering the infill is a fantastic way to lower part volume and cost. supplies 3 different infill patterns for FDM:

- Ultralight: ultralight infill components are full of a solitary zig-zag pattern. This is the lightest and least expensive infill alternative.

- Light: light infill parts are filled with a double cross-hatch pattern. This choice provides boosted rigidness and is lighter than a total strong infill.

- Solid: solid infill parts are totally filled up for the greatest thickness. This is the heaviest and most pricey choice.

2: Lower Z-height

3D printers produce components on a layer-by-layer basis, fusing or bonding one cross-section at once until the whole object is created. For powder bed fusion processes, such as SLS, HP Multi Jet Combination, and DMLS, the machines thaw layers of powder and afterwards relocates incrementally up to produce the next degree. For extruding/jetting procedures, the product is ejected through a printhead nozzle. Shanty town and DLS processes balance layers and remedy times. For every layer, which differs from 0.001″– 0.013″ in height relying on the process, there is a mechanical movement that can add a great deal of time to a part’s build. Coupling the vertical movement, recoating of material layers, and even step-by-step automated printhead cleaning can add hours of equipment time.

Minimizing the upright Z-height of the part is an excellent method to keep printing costs down. Sometimes splitting components is also much more economical than boosting height. With a reduced part height, the impact of the equipment task between layers is reduced and the costs are concentrated much more on straight product prices.

SLS, HP Multi Jet Fusion, FDM, SLA, DLS, PolyJet, and DMLS procedures all make use of printers with numerous maximum develop platform dimensions. These are integrated into our AI-based estimating algorithms, which means that parts that can be constructed lying on their side (flat) often tend to be extra cost-efficient than those that need to be built with their lengthiest face in the upright direction.

Here are some excellent “finest practices’ lengths to keep in mind when developing your part for a particular procedure. Remaining under these will typically ensure a lower-priced part. An additional method to think of it is that if you remain under half the offered platform size then you can get numerous components on the develop, allowing some overhanging expenses to be shared.

3: Pick the Right Process

Various 3D printing processes have distinctive rate points, which indicates selecting the procedures that fall within your budget plan (without endangering part feature) can assist you reduce costs.

SLS or HP Multi Jet Combination printing processes using Nylon 12 is nearly constantly one of the most affordable process to make plastic parts wholesale. This is mostly driven by the fact that SLS parts can be published in a household build which allows lots of items to be made “free-floating” in the powder bed. This enables quantity discount rates to be put on extra things of the exact same part in addition to included special components in the exact same quote. For large flat parts, FDM ABS-M30 or ASA is the go-to procedure as a result of the system’s ability to develop components promptly with different materials, infill, and shade options.

One of the most affordable procedure for 3D printing steels is binder jetting. This budget-friendly metal 3D printing process can develop intricate components accurately without tooling, which reduces producing lead times from months to days. We likewise advise binder jetting as a financial choice to steel spreading in reduced volumes.

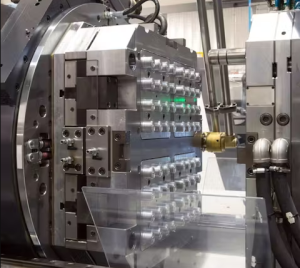

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

4: Select the Right Product

Just like exactly how various 3D printing systems have various cost-drivers, so as well do various materials. Some products are extra common– usually called “asset” products– while others are crafted to have higher rigidity and heat-resistance– these are specialized “engineered” products. Depending on your phase of product advancement, you ought to pick a material that matches your acceptance criteria for that stage.

For example, if you are in the fast prototyping phase and require to confirm your idea or examine the fit of a component within an assembly, you may want to pick ABS for FDM or Nylon 12 for SLS. These are inexpensive materials with acceptable mechanical buildings and function resolution for many applications. When you require a higher-resolution product to model the last geometry, a more pricey Accura or Somos material for stereolithography 3D printing might be the most effective 3d printing product. For a useful or late-stage prototype, you may intend to select a strengthened, high-performance material like SLS nylon 12 carbon-filled or FDM ULTEM 9085 to evaluate the component in its end atmosphere. These crafted materials ought to be selected just at later phases in your product growth cycle to minimize your material prices and save money on 3D printing.

5: Follow 3D Printing Style Finest Practices

There are a couple of standard style approaches you must adhere to whatever your part is constructed from or what procedure it’s printed in. Doing so will certainly reduce the variety of times you will need to revise and reprint a style, decreasing the general price of production. Some layout techniques consist of:

Designing with even wall densities will minimize any thermal discrepancies or damage Including clearance in between features to guarantee features settle during printing, along with lowering confined hollows to make sure there are no excess products stuck in between attributes.

Filleting all internal and external corners to decrease acute tension points and boost the total performance of the part Reducing the number of cantilevers or making these parts replaceable with off-the-shelf components given that they might damage throughout 3D printing.