Yes, carbon fiber can be used in injection molding, typically in the form of carbon fiber-reinforced plastic (CFRP). This involves combining carbon fibers with a polymer matrix to create a composite material that offers enhanced mechanical properties. Here’s a detailed overview:

Carbon Fiber Reinforced Plastic (CFRP)

Composition

- Polymer Matrix: Common polymers used include thermoplastics like polyamide (nylon), polycarbonate (PC), polypropylene (PP), and acrylonitrile butadiene styrene (ABS).

- Carbon Fibers: These fibers can be short, long, or continuous, with short and long fibers being more commonly used in injection molding. Continuous fibers are typically used in other processes like lay-up and filament winding.

Properties and Advantages

- High Strength-to-Weight Ratio: Carbon fiber composites are significantly stronger and lighter than many traditional materials, making them ideal for high-performance applications.

- Stiffness: The addition of carbon fibers increases the stiffness of the material, which is beneficial in applications requiring rigidity.

- Thermal Stability: Carbon fibers provide excellent thermal stability and resistance to high temperatures.

- Electrical Conductivity: Depending on the polymer matrix, carbon fiber composites can also offer enhanced electrical conductivity.

Injection Molding Process

- Molding Equipment: Standard injection molding machines can be used with some modifications to handle the abrasive nature of carbon fibers and ensure proper mixing and distribution within the polymer matrix.

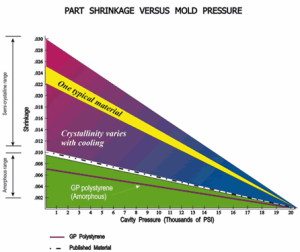

- Processing Conditions: Parameters like temperature, pressure, and cooling rates need to be optimized to ensure the integrity of the carbon fibers and the quality of the final part.

- Tooling: The molds need to be designed to withstand the abrasive nature of carbon fibers, often requiring the use of harder materials or coatings to reduce wear and tear.

Applications

- Automotive Industry: Used in components such as brackets, housings, and structural parts to reduce weight and improve fuel efficiency.

- Aerospace: Utilized in lightweight yet strong components, contributing to overall weight reduction and fuel savings.

- Consumer Electronics: Employed in cases and structural parts for devices that require a combination of strength, durability, and lightweight properties.

- Sports Equipment: Used in high-performance sports gear like bicycle frames, golf clubs, and tennis rackets for enhanced performance.

Challenges

- Cost: Carbon fiber materials are generally more expensive than traditional materials, which can be a limiting factor for some applications.

- Wear and Tear on Equipment: The abrasive nature of carbon fibers can cause increased wear on molds and machinery, requiring more frequent maintenance and potential replacements.

Your Partner in Custom Injection Molding

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Sources for Further Reading

- Plastics Technology: Injection Molding with Carbon Fiber

- Composites World: Carbon Fiber Composites

- ResearchGate: Processing and Applications of Carbon Fiber-Reinforced Thermoplastics

These sources provide comprehensive information on the use of carbon fiber in injection molding, detailing the benefits, challenges, and applications of CFRP in various industries.

Related Conten: Plastic Assembly Decoration