ABS (Acrylonitrile Butadiene Styrene) and Hylon (a type of nylon, typically reinforced with glass fiber) can potentially use the same injection mold, but several factors must be considered to ensure compatibility and optimal performance. Here’s an overview of the key considerations:

Key Considerations for Using the Same Mold

1. Material Properties

- ABS: Known for its strength, rigidity, and ease of processing, ABS has a lower melting temperature and lower shrinkage compared to nylon.

- Hylon: Typically a reinforced nylon with higher melting temperatures and greater shrinkage. It also has higher tensile strength and heat resistance.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

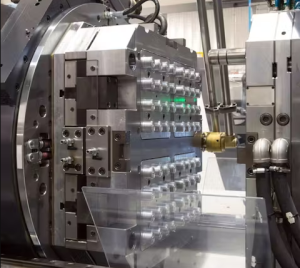

2. Mold Design and Construction

- Tolerance and Shrinkage: The mold must be designed to accommodate the different shrinkage rates of ABS and Hylon. Nylon’s higher shrinkage rate may require adjustments in the mold dimensions to ensure accurate part dimensions.

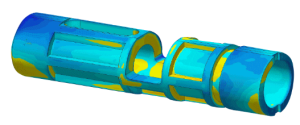

- Cooling System: The cooling system must be capable of handling the different thermal properties of the materials. Nylon often requires more efficient cooling due to its higher processing temperatures.

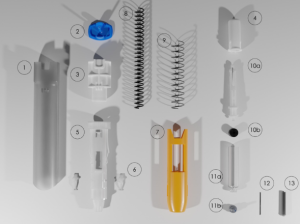

- Ejection System: The ejection system should be robust enough to handle the higher rigidity and potential brittleness of glass-filled nylon compared to ABS.

3. Processing Parameters

- Temperature: Injection molding parameters such as melt temperature, mold temperature, and cooling time will differ significantly between ABS and Hylon. These parameters must be adjusted accordingly for each material.

- Injection Pressure: Nylon typically requires higher injection pressures than ABS due to its higher viscosity.

4. Mold Wear and Maintenance

- Wear and Tear: Glass-filled nylon (Hylon) can be more abrasive and cause more wear on the mold than ABS. Molds used with Hylon may require more frequent maintenance and potentially harder steels or surface treatments to withstand the increased abrasion.

Practical Steps for Using the Same Mold

- Mold Design Adaptations:

- Incorporate interchangeable mold inserts if frequent switching between ABS and Hylon is expected. This allows for adjustments specific to each material without requiring a completely new mold.

- Adjustable Processing Settings:

- Ensure the injection molding machine can easily switch between the different processing parameters required for ABS and Hylon.

- Regular Maintenance:

- Implement a rigorous maintenance schedule to check for wear and tear, especially when using glass-filled nylon, to ensure mold longevity.

Conclusion

While ABS and Hylon can potentially use the same injection mold, careful consideration of material properties, mold design, processing parameters, and maintenance requirements is essential. By addressing these factors, manufacturers can optimize the injection molding process for both materials, ensuring high-quality parts and efficient production.

Related Conten: Rapid Injection Molding