Calculating cavity pressure in injection molding is crucial for ensuring the quality and integrity of molded parts. Cavity pressure refers to the pressure exerted by the molten plastic on the cavity walls during the injection molding process. It provides insights into the filling behavior, material flow, and potential defects in the molded part. Here’s a step-by-step guide on how to calculate cavity pressure:

1. Understand the Variables

- Injection Pressure: The pressure applied by the injection molding machine to push molten plastic into the mold cavity.

- Cavity Area: The projected area of the part in the mold cavity.

- Cavity Volume: The volume of the part cavity into which the molten plastic is injected.

- Material Properties: Include melt density (ρ), injection temperature, and viscosity (η).

2. Basic Formula

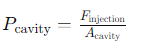

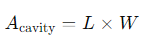

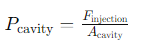

The cavity pressure (P_cavity) can be calculated using the following formula:

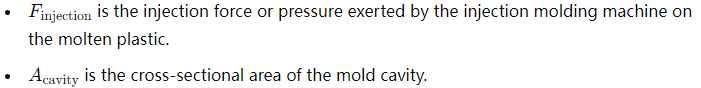

Where:

3. Calculation Steps

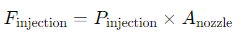

Step 1: Determine Injection Force (F_injection)

The injection force can be calculated using:

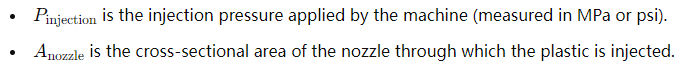

Where:

[elementor-template id=”4330″]

Step 2: Calculate Cavity Area (A_cavity)

The cavity area (A_cavity) is the projected area of the part in the mold cavity. For simple geometries, this can be calculated using:

Where:

- L is the length of the part in the mold cavity.

- W is the width of the part in the mold cavity.

For more complex geometries, the cavity area may need to be calculated using CAD software or mold design specifications.

Step 3: Calculate Cavity Pressure (P_cavity)

Finally, use the formula to calculate cavity pressure:

Example Calculation

Assume the following parameters:

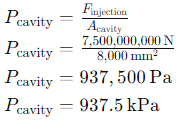

- Injection pressure (P_injection): 150 MPa (150,000,000 Pa)

- Nozzle area (A_nozzle): 50 square millimeters (50 mm²)

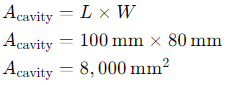

- Part dimensions (L × W): 100 mm × 80 mm

Step 1: Calculate Injection Force (F_injection)

Step 2: Calculate Cavity Area (A_cavity)

Step 3: Calculate Cavity Pressure (P_cavity)

[elementor-template id=”4331″]

Considerations

- Material Behavior: The viscosity and temperature of the molten plastic influence its flow behavior and thus the cavity pressure.

- Pressure Variation: Cavity pressure can vary during the injection process due to factors like injection speed, mold temperature, and material properties.

- Simulation Software: Advanced injection molding simulation software can provide more accurate predictions of cavity pressure based on detailed material and process parameters.

By accurately calculating cavity pressure, manufacturers can optimize injection molding processes, minimize defects, and ensure consistent part quality throughout production runs.

Related Conten: Prototype Manufacturing

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|