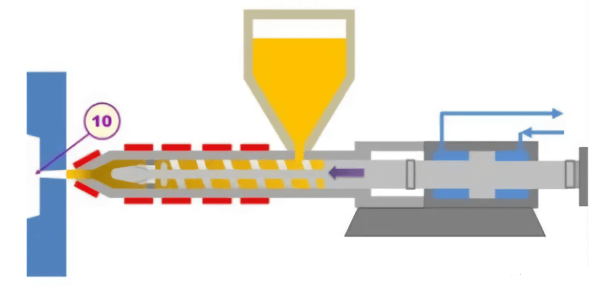

Calculating the barrel capacity of an injection molding machine is crucial for understanding the machine’s ability to handle a specific volume of plastic material during each injection cycle. Barrel capacity is typically measured in terms of shot size, which is the maximum volume of plastic that can be injected in one cycle. This capacity is often specified in ounces (oz), grams (g), or cubic centimeters (cc). Here’s a step-by-step guide on how to calculate the barrel capacity:

Step-by-Step Calculation

1. Understand the Units

- Volume: The barrel capacity can be expressed in cubic centimeters (cc), grams (g), or ounces (oz).

- Density: The density of the plastic material being used is necessary if you need to convert between volume and mass.

2. Basic Formula

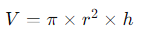

The volume of the barrel (V) can be calculated using the formula for the volume of a cylinder:

Where:

- π (Pi) is approximately 3.14159.

- r is the radius of the barrel.

- h is the stroke length of the screw (the length over which the screw travels during injection).

3. Measurement of Parameters

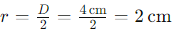

- Radius (r): Measure the inner diameter (D) of the barrel and divide by 2 to get the radius.

- Stroke Length (h): This is the maximum travel distance of the screw inside the barrel.

[elementor-template id=”4330″]

4. Convert to Appropriate Units

Ensure all measurements are in consistent units (e.g., cm or mm). If necessary, convert to cubic centimeters for volume calculations.

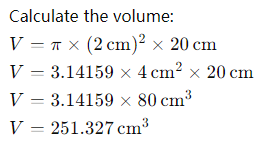

5. Example Calculation

Assume the following measurements:

- Inner diameter (D) of the barrel: 4 cm (40 mm)

- Stroke length (h): 20 cm (200 mm)

Calculate the radius:

Calculate the volume:

So, the barrel capacity is approximately 251.3 cubic centimeters (cc).

6. Convert to Mass if Necessary

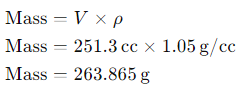

To convert the volume to mass, you need the density (ρ\rhoρ) of the plastic material in grams per cubic centimeter (g/cc). For example, if the density of the plastic is 1.05 g/cc:

[elementor-template id=”4331″]

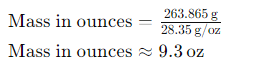

7. Convert to Ounces if Necessary

To convert grams to ounces, use the conversion factor (1 oz ≈ 28.35 g):

So, the barrel capacity is approximately 9.3 ounces of plastic.

Conclusion

By following these steps, you can calculate the barrel capacity of an injection molding machine. This capacity helps in determining the maximum shot size and ensuring the machine is suitable for producing the desired parts. Consistent units and accurate measurements are crucial for precise calculations.

Related Conten: Prototype Injection Molding

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|