Home » Case Products » Understanding Injection Molding Cost: Factors and Considerations

Understanding Injection Molding Cost: Factors and Considerations

Injection molding is a popular manufacturing process used to produce high-quality plastic parts in large volumes. However, understanding the cost associated with injection molding is crucial for businesses looking to optimize their production processes. At DTG injection molding, we provide comprehensive insights into injection molding costs, helping you make informed decisions.

Key Factors Influencing Injection Molding Cost

- Material Selection: The type of plastic material used significantly impacts the overall cost. High-performance materials such as PEEK or Ultem are more expensive than standard materials like polypropylene or ABS. The choice of material depends on the part’s application, required properties, and performance criteria.

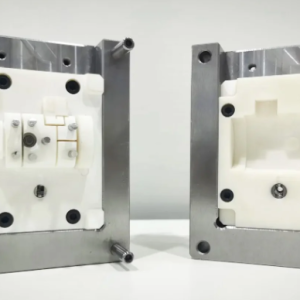

- Mold Complexity: The complexity of the mold design affects the cost. Complex molds with intricate geometries, undercuts, and tight tolerances require advanced manufacturing techniques and longer production times, leading to higher costs. Multi-cavity molds, which produce multiple parts per cycle, also tend to be more expensive than single-cavity molds.

- Production Volume: Higher production volumes typically reduce the cost per part due to economies of scale. While the initial mold creation is costly, spreading this cost over a large number of parts reduces the unit price. Low-volume production runs generally have higher costs per part due to the significant setup and mold costs.

- Cycle Time: The time it takes to complete one injection molding cycle directly affects the overall cost. Shorter cycle times increase production efficiency and reduce labor and overhead costs. Factors influencing cycle time include mold cooling time, part design, and material flow characteristics.

- Labor and Overhead: Labor costs for operating injection molding machines and maintaining molds contribute to the overall cost. Additionally, overhead costs such as energy consumption, machine maintenance, and facility costs need to be considered.

- Secondary Operations: Post-molding operations such as trimming, assembly, painting, or printing add to the total cost. Depending on the complexity and extent of these secondary operations, the cost can vary significantly.

How to Optimize Injection Molding Costs

- Material Optimization: Choose the most cost-effective material that meets the performance requirements of your part. Work with your supplier to identify alternatives that may reduce costs without compromising quality.

- Design for Manufacturability (DFM): Simplify part and mold designs to minimize complexity and reduce manufacturing costs. Collaborate with experienced mold designers to optimize designs for efficient production.

- Increase Production Volumes: Higher volumes can spread the mold cost over more parts, reducing the cost per unit. Consider forecasting demand accurately to plan for optimal production runs.

- Reduce Cycle Time: Optimize molding parameters to achieve the shortest possible cycle time without affecting part quality. This can significantly reduce labor and overhead costs.

Contact Us for Cost-Efficient Injection Molding Solutions

At DTG injection molding, we specialize in providing cost-effective injection molding solutions tailored to your specific needs. Our experienced team is dedicated to helping you optimize production and reduce costs while maintaining the highest quality standards.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Injection Molded Plastic Containers

Read more -

High-Quality Cellulose Acetate Injection Molding Services

Read more -

Premium Silicone Injection Mold Solutions for Superior Quality

Read more -

Customized Injection Molding ABS Plastic Product/Plug/Cover/Caps

Read more -

Innovative 3D Printed Injection Mold Solutions

Read more -

Leading Mold Injection Manufacturer – DTG Injection Molding

Read more