Home » Case Products » High-Quality Cellulose Acetate Injection Molding Services

High-Quality Cellulose Acetate Injection Molding Services

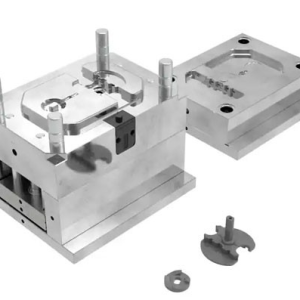

we specialize in cellulose acetate injection molding, offering environmentally friendly, high-performance, and precise components for a variety of industries. Our advanced technology and extensive expertise ensure that every cellulose acetate part we produce meets the highest standards of quality and performance.

Why Choose DTG Injection Molding for Cellulose Acetate Injection Molding?

1. Expertise in Cellulose Acetate: Our team has extensive experience working with cellulose acetate, a sustainable and biodegradable thermoplastic derived from natural sources like wood pulp and cotton. This material offers excellent optical properties, toughness, and chemical resistance, making it ideal for various applications.

2. Advanced Injection Molding Technology: We utilize state-of-the-art injection molding equipment to produce cellulose acetate parts with exceptional precision and consistency. Our advanced machinery allows us to create complex geometries and intricate details with ease, ensuring high-quality results every time.

3. Custom Solutions: Every project is unique, and we provide customized cellulose acetate injection molding solutions tailored to your specific requirements. Whether you need parts with specific mechanical properties, unique designs, or precise dimensions, our team collaborates with you to deliver parts that meet your exact needs.

4. Environmentally Friendly: Cellulose acetate is a renewable and biodegradable material, making it an environmentally responsible choice for various applications. By choosing cellulose acetate injection molding, you contribute to sustainability and reduce your environmental footprint.

5. Wide Range of Applications: Cellulose acetate injection molding is ideal for a variety of industries, including eyewear, consumer electronics, packaging, and medical devices. Our versatile approach enables us to produce parts that meet the specific needs of different applications, enhancing the functionality and aesthetic appeal of your products.

6. Efficient Production Processes: Our efficient production processes and advanced technology enable us to deliver high-quality cellulose acetate parts quickly and cost-effectively. We strive to provide competitive pricing and rapid turnaround times to help you stay ahead of the competition.

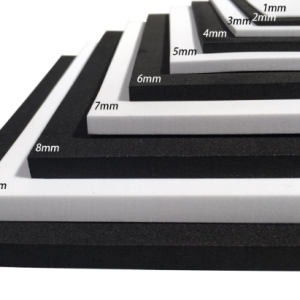

7. Material Selection Expertise: We offer a wide range of cellulose acetate grades and formulations to suit various applications, ensuring that your components have the necessary properties for their intended use, such as high transparency, impact resistance, and chemical stability.

8. Comprehensive Support: From initial design consultation to final production and delivery, our team provides comprehensive support throughout your project. We offer expert guidance, technical assistance, and dedicated customer service to ensure your complete satisfaction.

Experience the Benefits of Cellulose Acetate Injection Molding with DTG Injection Molding

Enhance your product development with our expert cellulose acetate injection molding services. Contact DTG Injection Molding today to discuss your project and discover how our high-quality, precise cellulose acetate components can meet your specific needs and elevate your production capabilities.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Expert Design for Injection Molding Services

Read more -

Cheap Custom ABS PP PA6 Injection Plastic Molding

Read more -

Plastic Phototherapy Skin Beauty Equipments by Plastic Moulds Tool

Read more -

Premium Custom Injection Mold Services

Read more -

EVA Foam Injection Molding Solutions

Read more -

High-Performance Phenolic Injection Molding Services

Read more