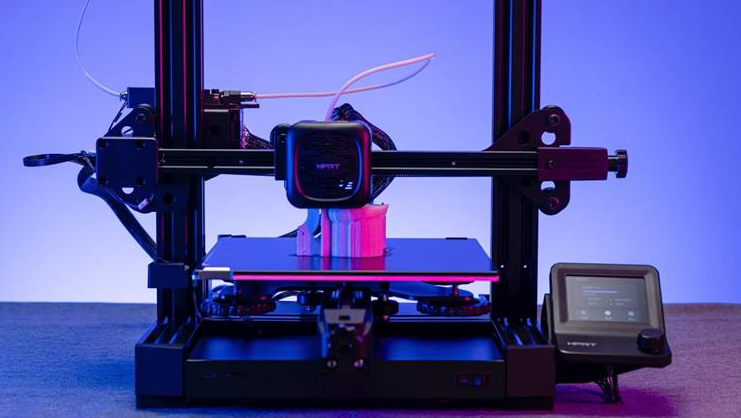

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), is one of the most widely used 3D printing technologies. Here’s an overview of how FDM 3D printing works, its advantages, and its common applications:

How FDM 3D Printing Works

- Material Extrusion:

- FDM printers use thermoplastic filaments, which are fed through an extruder.

- The filament is heated to its melting point inside a hot end.

- The melted material is then extruded through a nozzle.

- Layer-by-Layer Construction:

- The printer’s nozzle moves along the X and Y axes, depositing the molten material onto a build platform, layer by layer.

- After one layer is completed, the build platform lowers (or the print head rises) slightly along the Z-axis to start the next layer.

- Cooling and Solidification:

- As each layer is deposited, it cools and solidifies, bonding with the previous layer to form a cohesive structure.

[elementor-template id=”4330″]

Key Components of an FDM 3D Printer

- Extruder: Feeds the filament into the hot end and controls the flow of material.

- Hot End: Heats the filament to a semi-liquid state and extrudes it through the nozzle.

- Nozzle: Deposits the molten filament onto the build platform.

- Build Platform: The surface on which the 3D print is built; often heated to prevent warping.

- Stepper Motors: Control the movement of the extruder and build platform along the X, Y, and Z axes.

Materials Used in FDM Printing

- PLA (Polylactic Acid): Biodegradable, easy to print, and ideal for beginners.

- ABS (Acrylonitrile Butadiene Styrene): Durable and heat-resistant, but can emit fumes.

- PETG (Polyethylene Terephthalate Glycol): Combines strength and flexibility, with good chemical resistance.

- Nylon: Strong, flexible, and abrasion-resistant, suitable for functional parts.

- TPU (Thermoplastic Polyurethane): Flexible and elastic, ideal for parts that need to bend or stretch.

Advantages of FDM 3D Printing

- Cost-Effective: FDM printers and materials are generally affordable, making them accessible to hobbyists and small businesses.

- Ease of Use: Many FDM printers are user-friendly and require minimal setup.

- Material Variety: A wide range of thermoplastics is available, catering to different applications and properties.

- Scalability: Suitable for both small-scale and large-scale prints.

Limitations of FDM 3D Printing

- Print Quality: Surface finish may have visible layer lines, requiring post-processing for a smoother finish.

- Print Speed: Can be slower compared to other 3D printing technologies, especially for detailed or large prints.

- Material Strength: Some FDM-printed parts may have weaker mechanical properties compared to other methods like SLS or SLA.

[elementor-template id=”4331″]

Common Applications of FDM 3D Printing

- Prototyping: Rapid creation of prototypes for design validation and testing.

- Functional Parts: Production of custom tools, jigs, and fixtures for manufacturing.

- Education: Used in schools and universities for teaching and research purposes.

- Hobby and DIY Projects: Popular among hobbyists for creating custom objects, models, and toys.

- Product Development: Helps in developing and iterating product designs quickly and cost-effectively.

FDM 3D printing is a versatile and accessible technology that has significantly impacted various industries by enabling rapid prototyping and small-scale manufacturing.

Related Conten: https://www.m-dtg.com/service/plastic-blow-molding/

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|