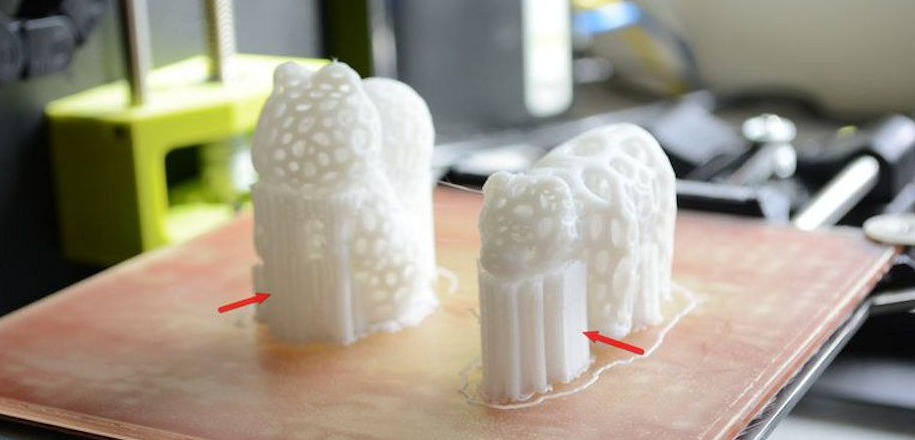

Removing supports from 3D prints is a crucial step to ensure your model looks clean and professional. Here’s a comprehensive guide on how to effectively remove supports from your 3D prints:

1. Understanding the Types of Supports

Before you begin, it’s essential to know the different types of supports:

- Breakaway Supports: These are designed to be manually snapped off. They are generally easier to remove but may leave surface marks.

- Soluble Supports: These dissolve in water or a specific solvent, leaving a smoother surface but requiring additional post-processing.

2. Preparing Your Workspace

Set up a clean, well-lit workspace with all necessary tools within reach. Essential tools include:

- Pliers (needle-nose or flush-cut)

- Hobby knife or scalpel

- Sandpaper or sanding sticks

- Tweezers

- Solvent (for soluble supports)

3. Removing Breakaway Supports

- Start with Pliers: Use needle-nose pliers to gently wiggle and break off larger support structures. Start from the outside and work your way in.

- Use a Knife for Precision: For smaller, more delicate areas, use a hobby knife to carefully cut away the supports. Be cautious to avoid damaging the model.

- Sanding and Smoothing: After removing the majority of the supports, use sandpaper or sanding sticks to smooth out any rough spots or marks left by the supports. Start with a coarse grit and move to a finer grit for a polished finish.

4. Removing Soluble Supports

- Prepare the Solvent: If you’re using soluble supports (like PVA or HIPS), prepare a bath with the appropriate solvent. For PVA, warm water is usually sufficient. For HIPS, a solution of d-Limonene is used.

- Submerge the Print: Place your 3D print in the solvent bath, ensuring it is fully submerged. Leave it for the recommended amount of time, typically several hours to overnight.

- Rinse and Dry: Once the supports have dissolved, rinse the print with clean water to remove any residual solvent. Allow the print to dry completely before further handling.

[elementor-template id=”4330″]

5. Post-Processing

- Filling and Smoothing: If there are any imperfections or gaps left by the supports, you can use a filler material to smooth these areas. Sanding can also help achieve a more uniform surface.

- Painting and Finishing: After supports are removed and the surface is smooth, you can proceed with painting or applying any other finishing touches to your model.

6. Safety Tips

- Wear Safety Gear: Always wear protective gloves and eye protection when handling sharp tools or solvents.

- Ventilation: Ensure your workspace is well-ventilated, especially when using solvents.

- Proper Disposal: Dispose of used solvents and support material according to local regulations to minimize environmental impact.

By following these steps, you can efficiently remove supports from your 3D prints, ensuring a high-quality finish that showcases your work’s detail and precision.

Related Conten: Prototype Manufacturing

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|