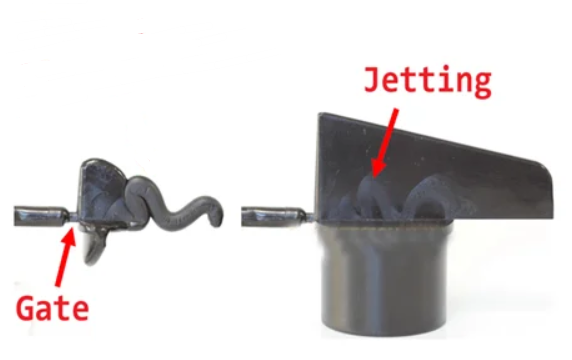

Jetting in injection molding refers to a defect that occurs when the molten plastic enters the mold cavity in a high-speed, narrow stream, causing it to cool and solidify unevenly. This results in a snake-like pattern on the surface of the molded part, leading to poor aesthetic and mechanical properties. Jetting is often caused by improper flow conditions, such as high injection speeds, incorrect gate design, or insufficient mold temperature.

Causes of Jetting

- High Injection Speed: When the injection speed is too high, the molten plastic enters the mold cavity with excessive force, causing it to “jet” rather than flow smoothly.

- Improper Gate Design: The location, size, and type of gate can influence the flow of molten plastic. A gate that is too small or improperly positioned can cause the plastic to enter the mold in a jet-like stream.

- Low Mold Temperature: If the mold is not heated sufficiently, the molten plastic can cool too quickly upon contact, leading to jetting.

- Viscosity of the Material: Highly viscous materials are more prone to jetting as they do not flow as smoothly as lower viscosity materials.

- Mold Design and Flow Path: Complex flow paths or sudden changes in the direction of flow within the mold can cause jetting if the molten plastic does not flow evenly.

[elementor-template id=”4330″]

Effects of Jetting

- Aesthetic Defects: The snake-like patterns on the surface of the part are visually unappealing and can affect the product’s appearance.

- Structural Weaknesses: Jetting can create areas of uneven density, leading to weak points in the part, which may affect its mechanical properties and durability.

- Surface Finish Issues: The surface of the part may have rough or uneven textures, which can be problematic for applications requiring smooth finishes.

Preventing Jetting

- Optimize Injection Speed: Reducing the injection speed can help ensure that the molten plastic flows smoothly into the mold rather than jetting.

- Proper Gate Design: Using appropriately sized gates and positioning them correctly can help distribute the flow of plastic more evenly. Fan gates or tab gates are often effective in reducing jetting.

- Increase Mold Temperature: Ensuring that the mold is heated to the correct temperature can help maintain the molten state of the plastic longer, allowing it to flow more evenly.

- Modify Flow Path: Adjusting the mold design to create a more gradual flow path can help reduce abrupt changes in flow direction, minimizing jetting.

- Use Flow Simulation Software: Utilizing mold flow analysis software can help predict and address potential jetting issues before the mold is manufactured.

[elementor-template id=”4331″]

Example of Preventing Jetting

Consider the production of a plastic housing for electronic devices:

- Optimizing Injection Speed: By reducing the injection speed, the molten plastic can enter the mold cavity more gradually, promoting a smoother flow.

- Gate Design Adjustments: Switching from a small pin gate to a larger fan gate can help spread the flow of plastic more evenly across the cavity.

- Increasing Mold Temperature: Raising the mold temperature ensures that the plastic remains molten longer, reducing the likelihood of it solidifying too quickly and causing jetting.

- Flow Path Modifications: Redesigning the mold to avoid sharp turns and sudden changes in flow direction can help the plastic fill the cavity more uniformly.

Conclusion

Jetting is a common defect in injection molding that results from improper flow conditions of molten plastic entering the mold cavity. It can lead to aesthetic and structural issues in the final product. By optimizing injection speed, improving gate design, increasing mold temperature, and modifying the flow path, jetting can be significantly reduced or eliminated, leading to higher-quality molded parts. Proper design and process control are essential to preventing jetting and ensuring the production of high-quality injection-molded components.

Related Conten: Prototype Injection Molding / Plastic Assembly Decoration

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|