Weld lines, also known as knit lines or flow lines, are surface defects that occur when two or more flow…

2024

Starting an injection molding machine involves a series of steps to ensure that the machine is set up correctly and…

Reducing part weight in injection molding is beneficial for cost savings, material efficiency, and improving product performance. Achieving weight reduction…

Calculating cavity pressure in injection molding is crucial for ensuring the quality and integrity of molded parts. Cavity pressure refers…

Calculating the barrel capacity of an injection molding machine is crucial for understanding the machine’s ability to handle a specific…

Flow marks, also known as flow lines, are surface defects that appear as streaks or patterns on the molded part….

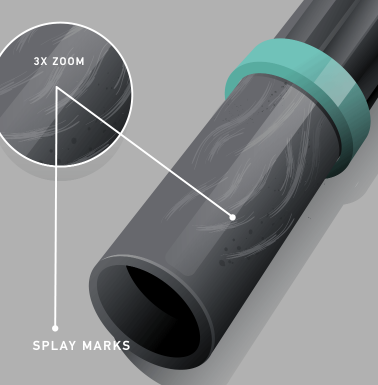

Splay, also known as silver streaking or silvering, is a common defect in injection molding characterized by streaks or lines…

Bubbles, also known as voids or air pockets, are a common defect in injection molding that can affect the quality…

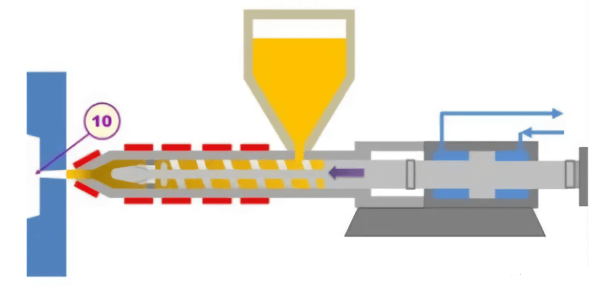

Injection molding machines are essential for producing plastic parts with precision, efficiency, and consistency. Understanding how these machines work can…

Injection molds are critical tools in the manufacturing industry, enabling the mass production of plastic parts with high precision and…